Multi-stage temperature difference frequency vibratory fluidization system and method for oxidizing and non-melting coal tar pitch pellets

A non-melting, vibrating fluidization technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of limited stacking height, slow oxidation heating rate, low production efficiency, etc., to reduce particle agglomeration. or channeling, the residence time is uniform, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

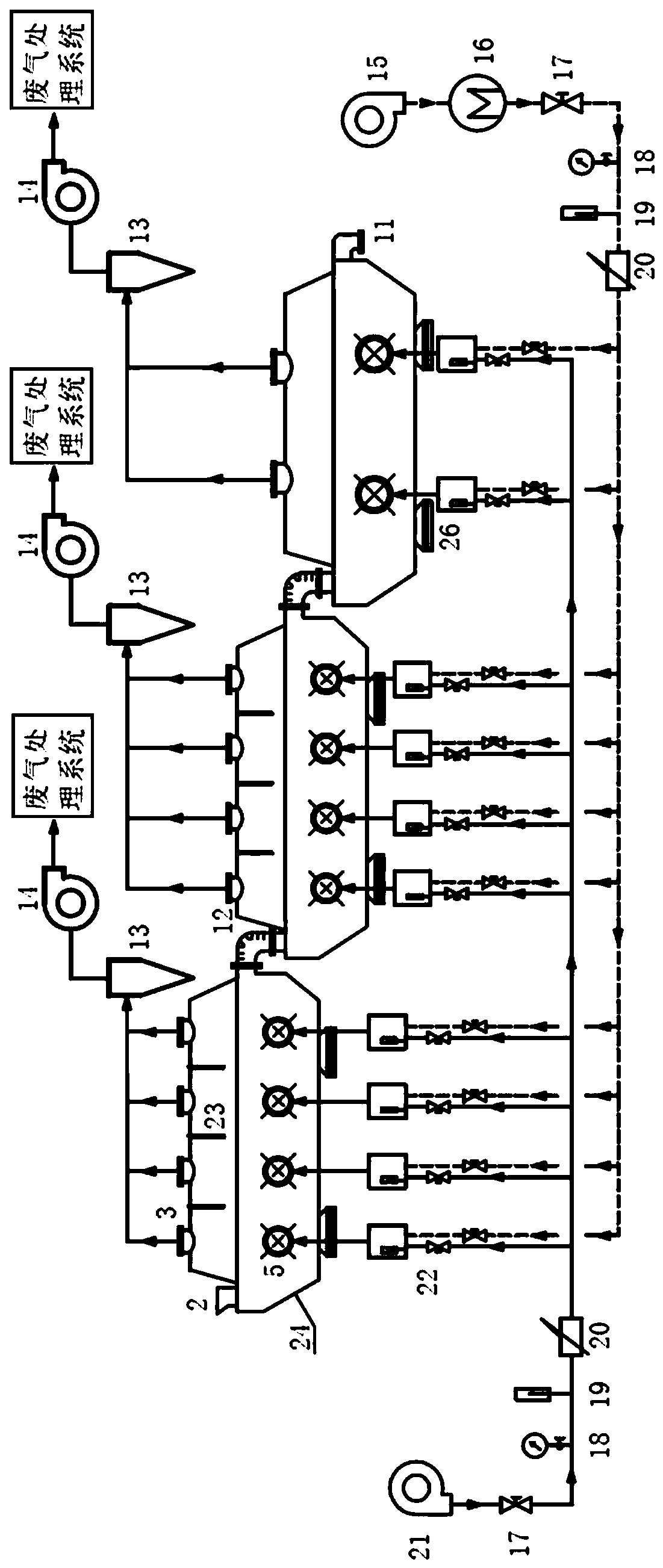

[0036] Attached below Figure 1~4 , taking the three-stage temperature-raising differential-frequency vibratory fluidization system as an example, the technical solution of the present invention will be described in detail.

[0037] The three-stage temperature difference frequency vibratory fluidization system for oxidation and non-melting of coal tar pitch balls includes three-stage fluidized bed reactors with different vibration frequencies and a temperature-controlled gas supply device.

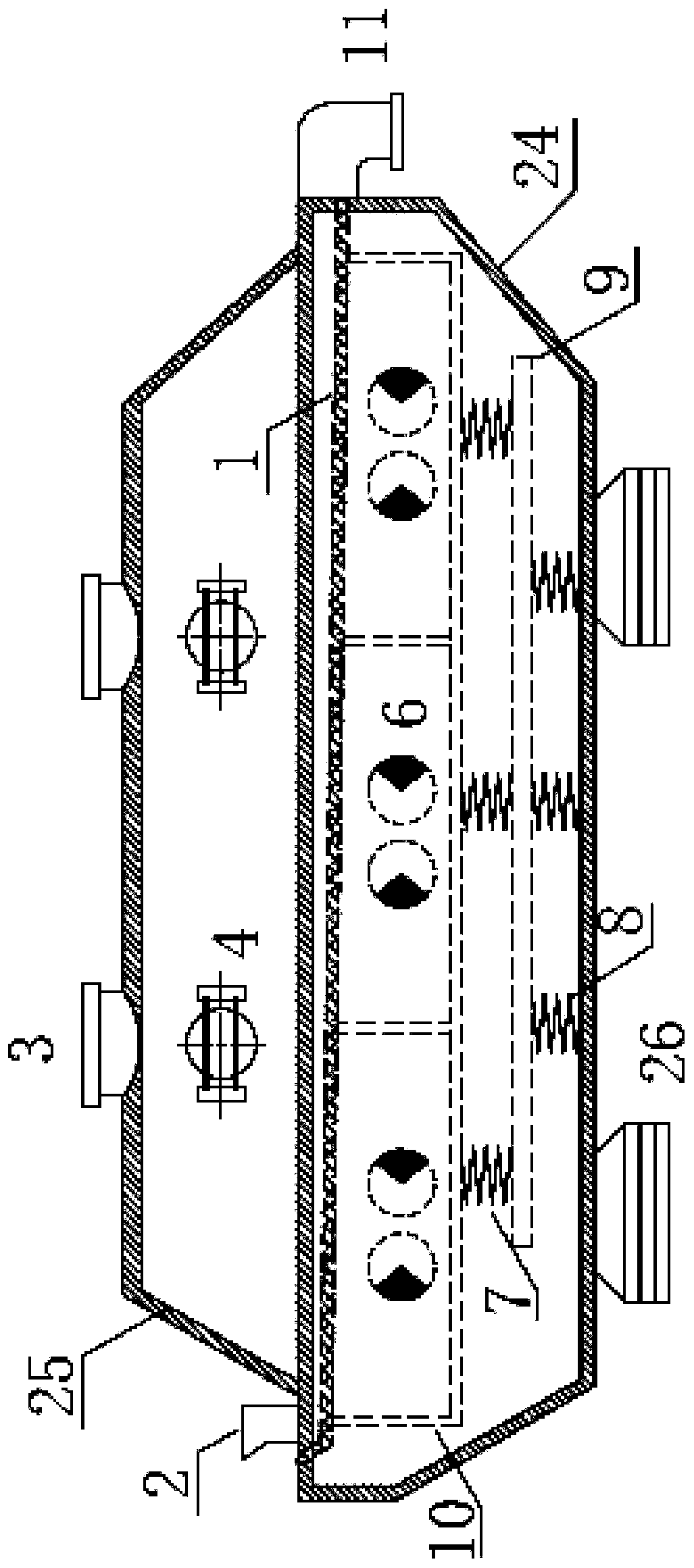

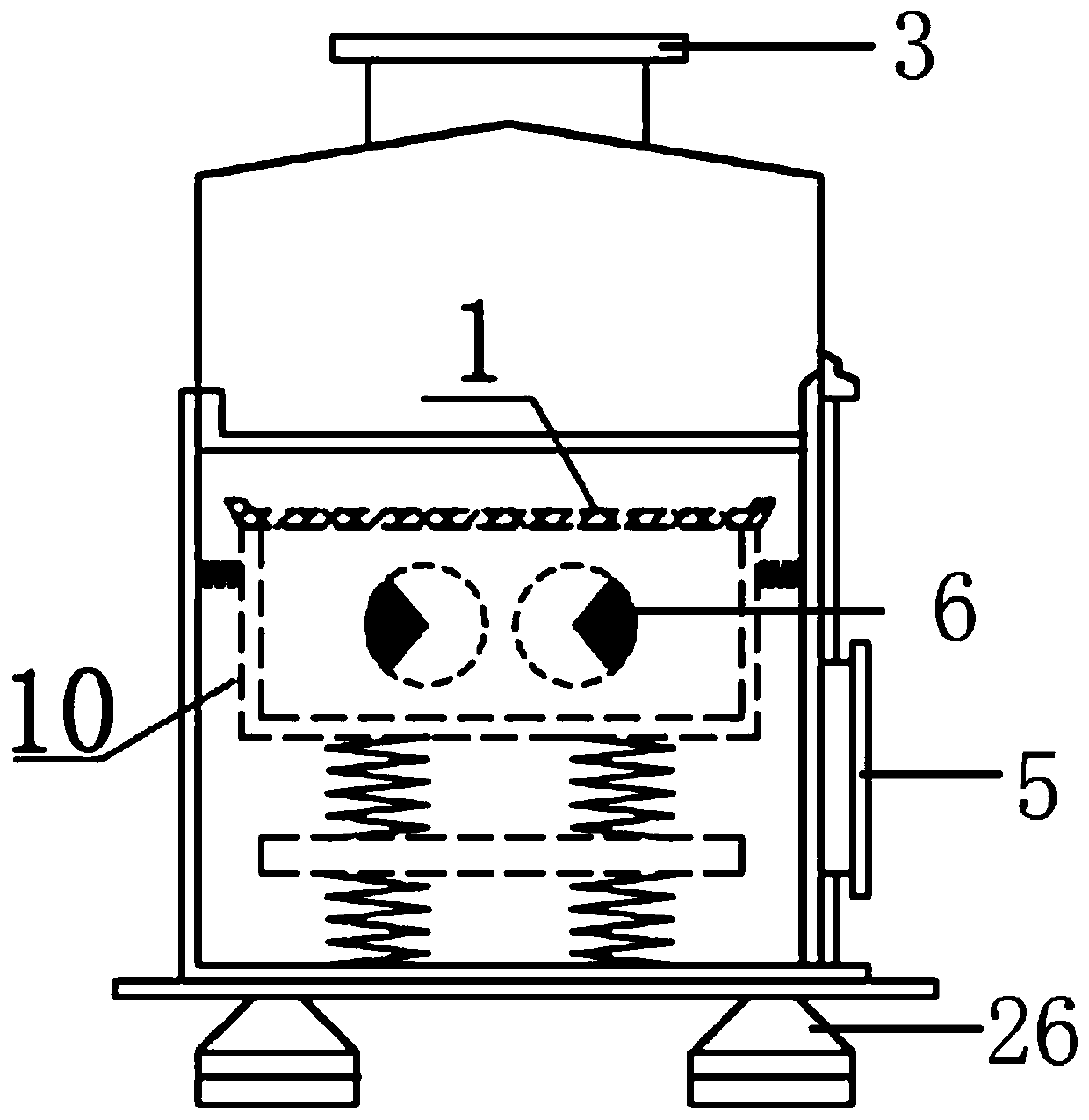

[0038] The three-stage vibrating fluidized bed reactor includes three sets of fluidized bed reactors and bed vibration devices. Each set of fluidized bed reactor includes porous distribution plate 1, feed inlet 2, discharge outlet 11, air inlet 5, air outlet 3, cleaning peep door 4, cyclone separator 13, exhaust fan 14, windshield 23, Shell 24 and insulation layer 25. The feed port 2 and the discharge port 11 are respectively arranged above the two ends of the porous distribution plate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com