A kind of impure steam collection and condensation equipment

A pure steam and condensing device technology, applied in the field of resource utilization of chemical products, can solve the problems of damaged pipelines, large delay, insensitive temperature adjustment, etc., and achieve the effect of reducing corrosion, small delay and good washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention provides many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

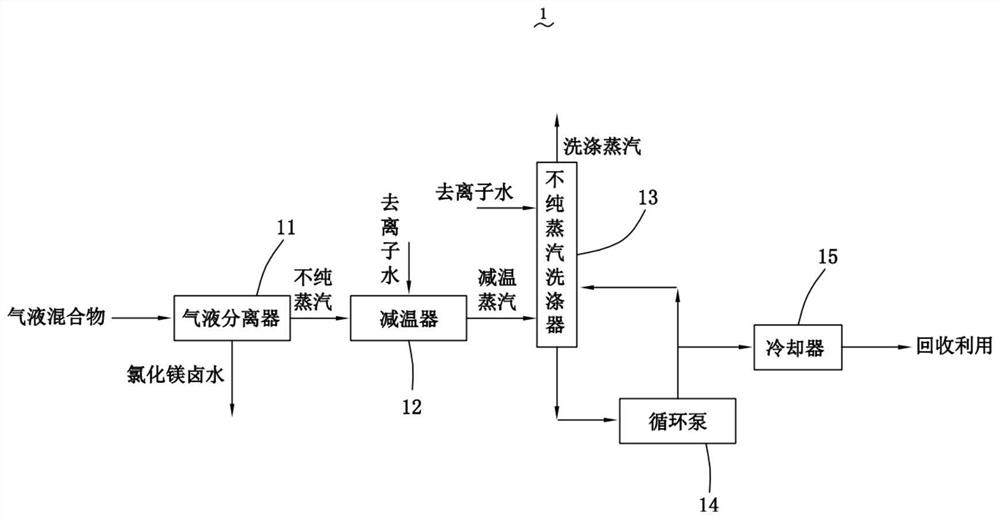

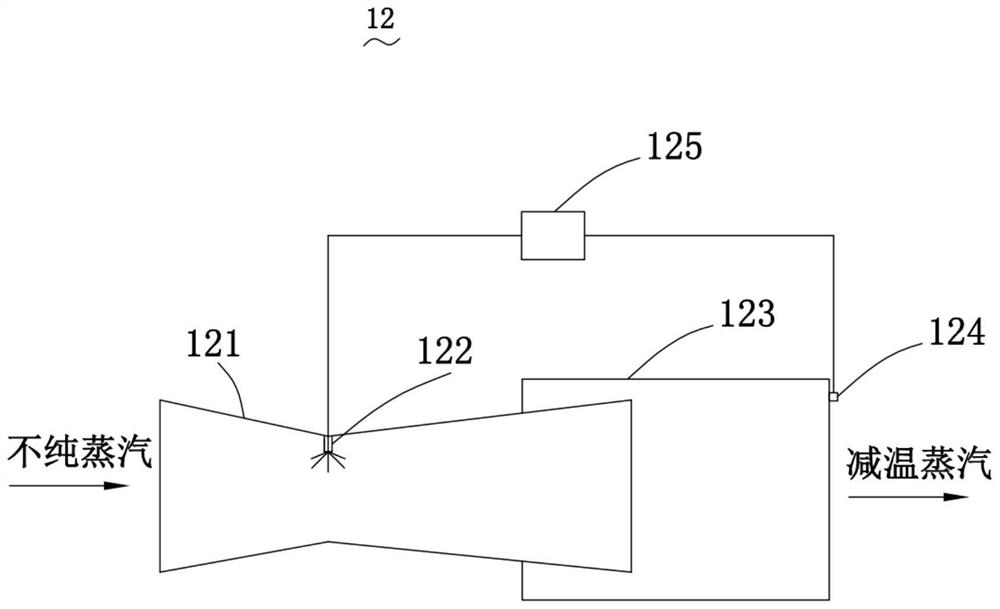

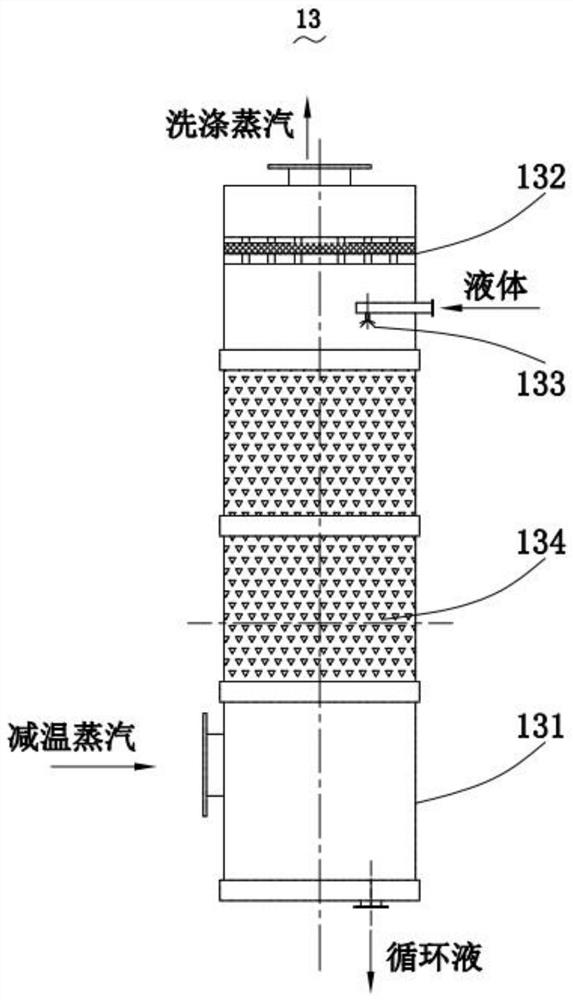

[0034] Such as figure 1 as shown, figure 1 It is a process flow diagram of a collection and condensation device for impure steam in a preferred embodiment of the present invention. This embodiment provides a collecting and condensing device 1 for impure steam, which is used to process the gas-liquid mixture containing magnesium chloride brine and impure steam produced during the preparation of high-purity anhydrous magnesium chloride, and complete the process of separation-lower temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com