Preparation method of oatmeal

A technology of oatmeal and oats, which is applied in food ingredients as antimicrobial preservation, food science, food preservation, etc. It can solve the problems of unhealthy and harmful, and achieve the effect of good taste, high nutritional content and excellent shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of preparation method of oatmeal, comprises the following steps:

[0019] (1) Mix oats, wheat and corn at a mass ratio of 1:0.4:0.24, pulverize and pass through a 200-mesh sieve to obtain composition A; mix okara and hazelnuts at a mass ratio of 1:0.54, pulverize and pass through a 200-mesh sieve, Composition B is obtained; the composition B is added to the composition A, and mixed to obtain the main component, the mass ratio of the composition A and the composition B in the main component is 1:0.09; the selected oats, wheat, corn, bean dregs and hazelnuts have a moisture content below 5%;

[0020] The bean dregs are prepared by the following method: mix soybeans and water at a mass ratio of 1:6.0, soak for 12 hours, pass the slurry through a 200-mesh sieve after beating, and take the solid residue; add egg white and yeast to the solid residue, mix well, and put Leave for 3 hours, the mass ratio of solid residue, egg white and yeast is 1:0.03:0.001...

Embodiment 2

[0025] Embodiment 2: a kind of preparation method of oatmeal, comprises the following steps:

[0026] (1) Mix oats, wheat and corn at a mass ratio of 1:0.30:0.20, pulverize and pass through a 200-mesh sieve to obtain composition A; mix okara and hazelnuts at a mass ratio of 1:0.50, pulverize and pass through a 200-mesh sieve, Composition B is obtained; the composition B is added to the composition A, and mixed to obtain the main component, the mass ratio of the composition A and the composition B in the main component is 1:0.08; the selected oats, wheat, corn, bean dregs and hazelnuts have a moisture content below 5%;

[0027] The bean dregs are prepared by the following method: mix soybeans and water at a mass ratio of 1:6.5, soak for 8 hours, pass the slurry through a 150-mesh sieve after beating, and take the solid residue; add egg white and yeast to the solid residue, mix well, and put Leave for 2 hours, the mass ratio of solid residue, egg white and yeast is 1:0.04:0.002...

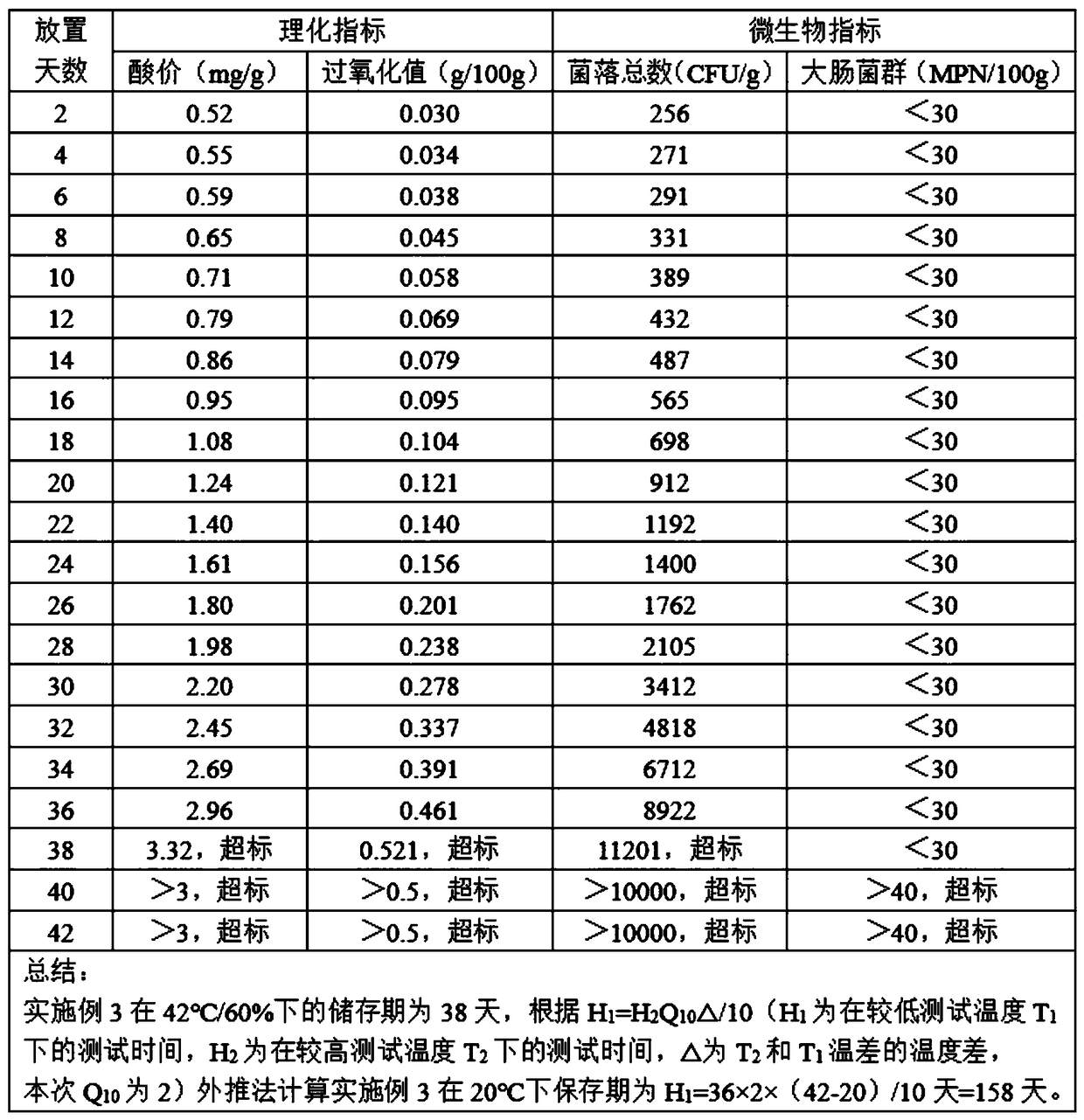

Embodiment 3

[0032] Embodiment 3: a kind of preparation method of oatmeal, comprises the following steps:

[0033] (1) Mix oats, wheat and corn at a mass ratio of 1:0.51:0.30, pulverize and pass through a 150-mesh sieve to obtain composition A; mix okara and hazelnuts at a mass ratio of 1:0.61, pulverize and pass through a 150-mesh sieve, Composition B is obtained; the composition B is added to the composition A, and mixed to obtain the main component, the mass ratio of the composition A and the composition B in the main component is 1:0.10; the selected oats, wheat, corn, bean dregs and hazelnuts have a moisture content below 5%;

[0034] The bean dregs are prepared by the following method: mix soybeans and water at a mass ratio of 1:6.5, soak for 8 hours, pass the slurry through a 150-mesh sieve after beating, and take the solid residue; add egg white and yeast to the solid residue, mix well, and put Leave for 2 hours, the mass ratio of solid residue, egg white and yeast is 1:0.04:0.002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com