Production device of preserved roxburgh rose fruits

A technology for production equipment and preserved fruit, which is applied in confectionery, confectionery industry, food processing and other directions, can solve the problems of unstable manpower operation time, increased labor intensity, low manual handling efficiency, etc., so as to reduce labor cost consumption and improve cleanliness. the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

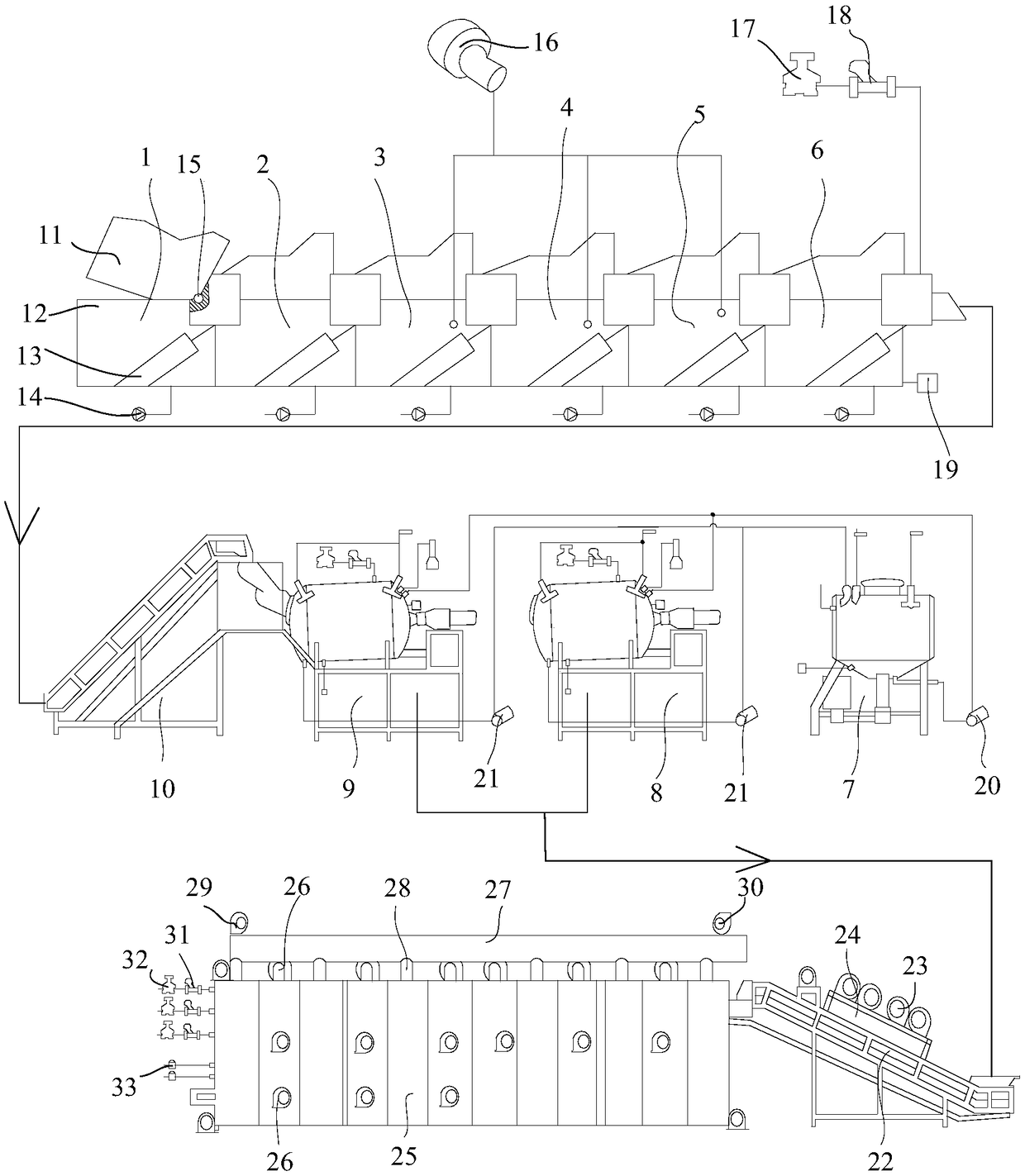

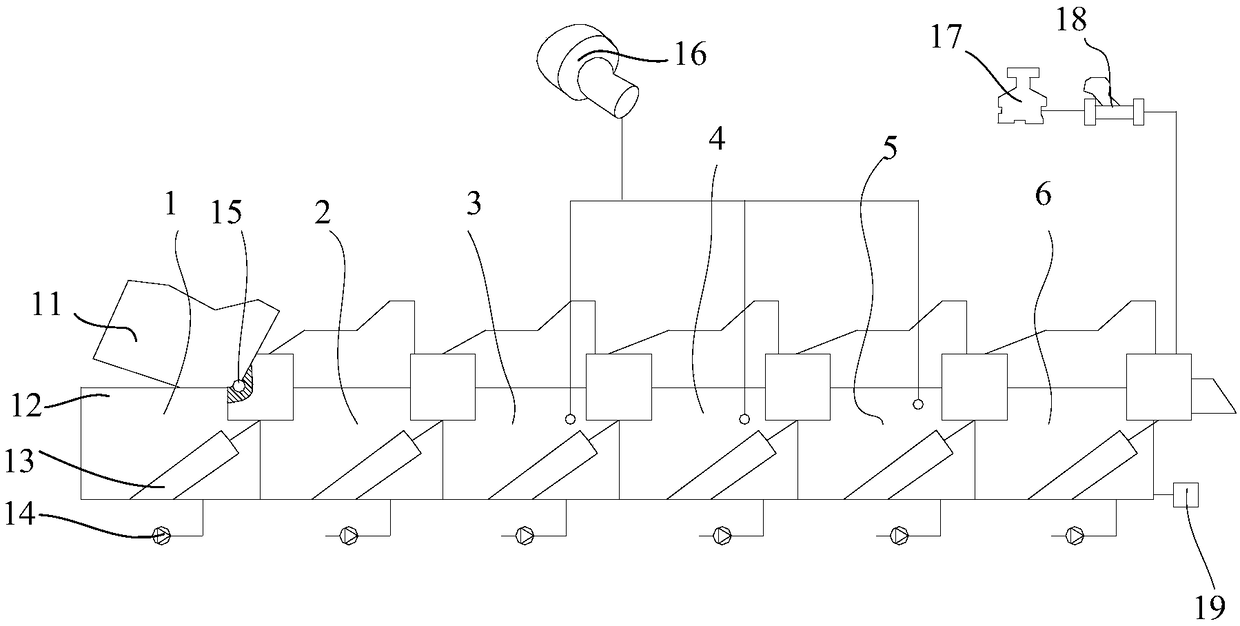

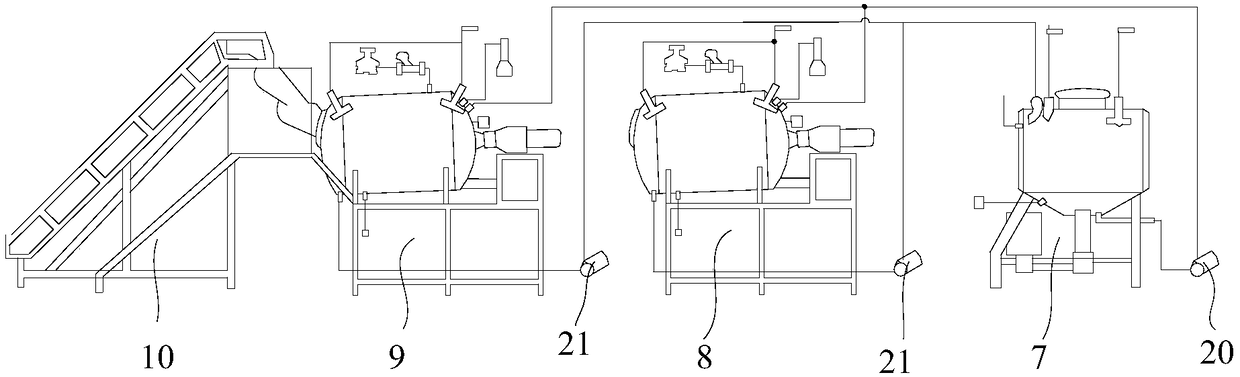

[0036] Such as Figure 1 to Figure 8 As shown, a kind of roxburghii preserved fruit production equipment in the present embodiment comprises: successively connected immersion cleaning pool 1, color protection pool 2, first cleaning pool 3, second cleaning pool 4, third cleaning pool 5, greening Pool 6, the first hoist 10, sugar dipping device, the second hoist 22 and dryer 25, the sugar dipping device is connected with a high-speed sugar dissolving tank 7; the first cleaning pool 3, the second cleaning pool 4 and the third cleaning The pool 5 is connected with a vortex air pump 16; the cleaning pool 6 is provided with a pipeline for feeding steam, and the pipeline is sequentially provided with a first stop valve 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com