Pneumatic tensioning wheel device

A tensioner device, pneumatic technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of reduced shock absorption capacity of the tensioner, abnormal belt wear, reduced durability, etc., to avoid The effect of reduced shock absorption, elimination of loose mounting bolts, and optimized response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

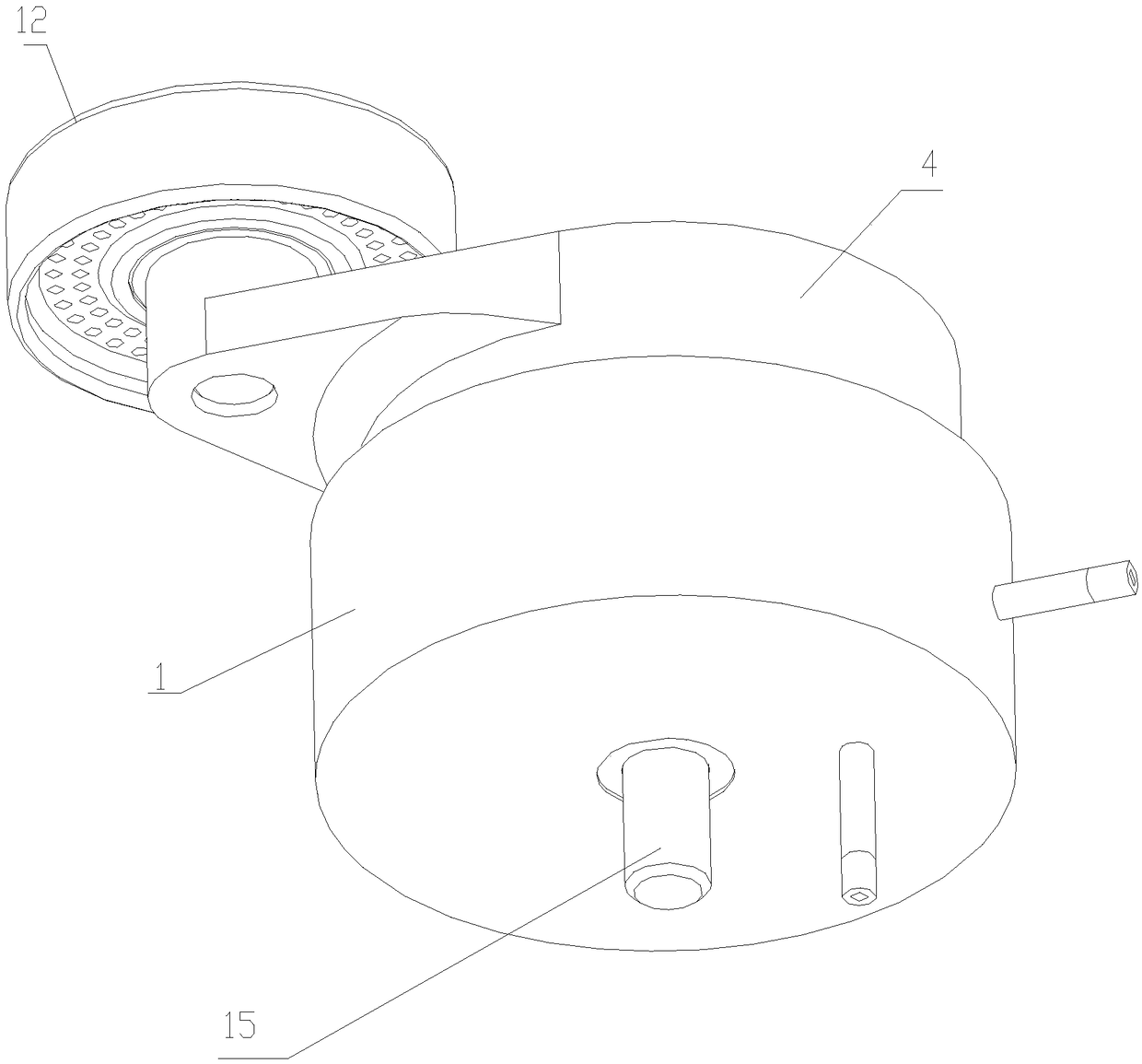

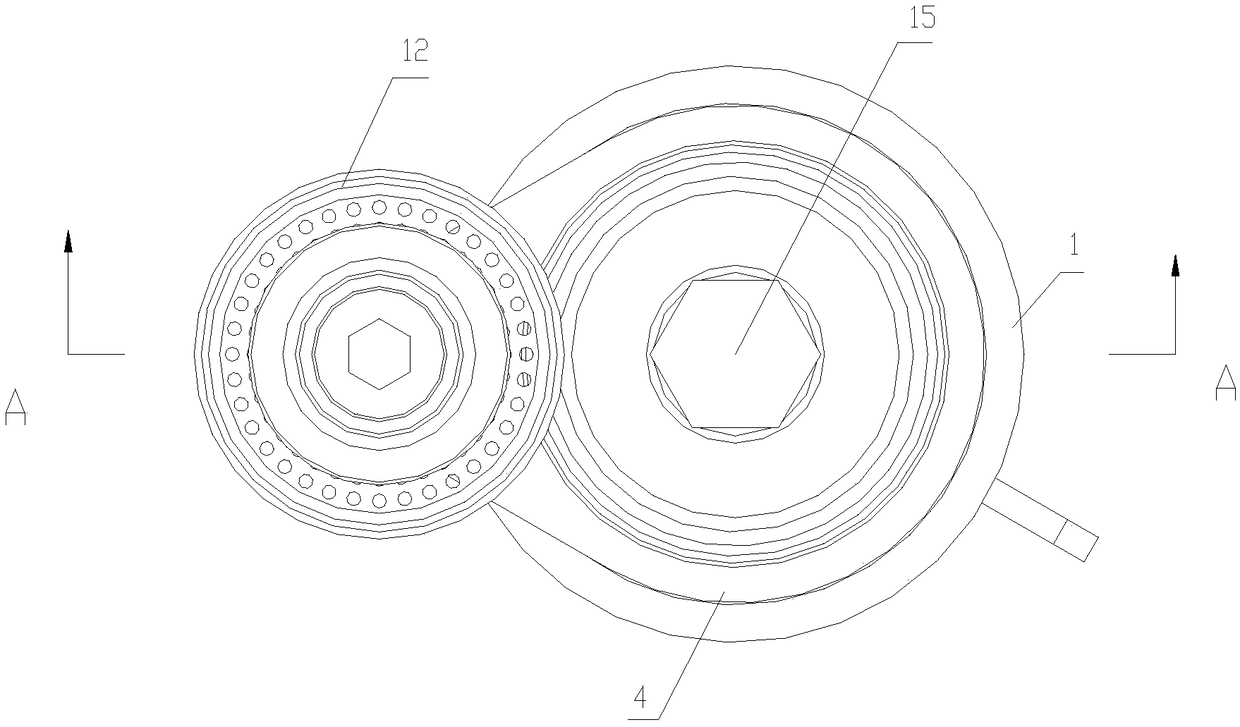

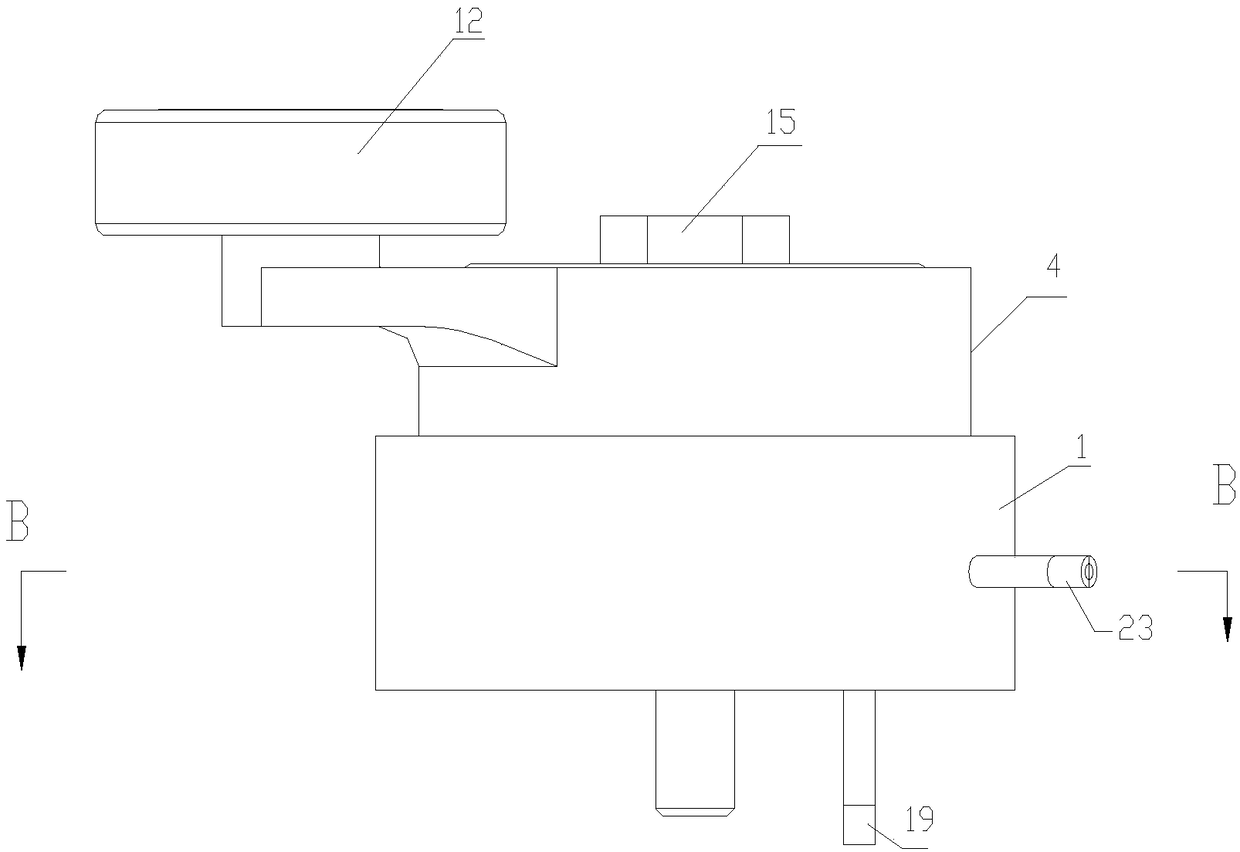

[0038] see Figure 1 to Figure 8 , this embodiment discloses a pneumatic tensioner device, which includes a cylindrical shell 1 with an opening at the top of the shell 1, and a mandrel extending vertically upward is fixed in the center hole of the bottom wall of the cavity of the shell 1 2. The bottom end surface of mandrel 2 is about 0.5mm higher than the bottom end surface of housing 1, which can prevent the mandrel 2 from contacting other supports when the mounting bolts 15 are tightened during the process of installing the tensioning wheel 12 device on other supports The mounting surface creates a false moment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com