Prefabricated type moulding bed and construction method thereof

A prefabricated assembly and membrane technology, which is applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of masonry quality and membrane size control, uneven quality of workers, and pollution discharge on construction sites. Achieve the effects of easy manual handling, stable personnel team, and excellent process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

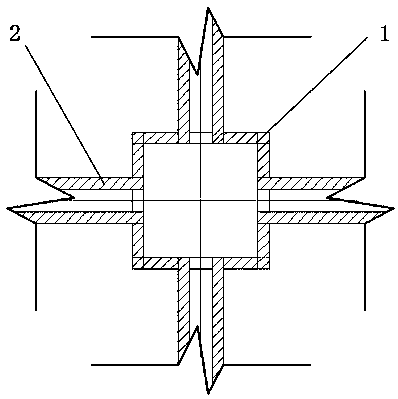

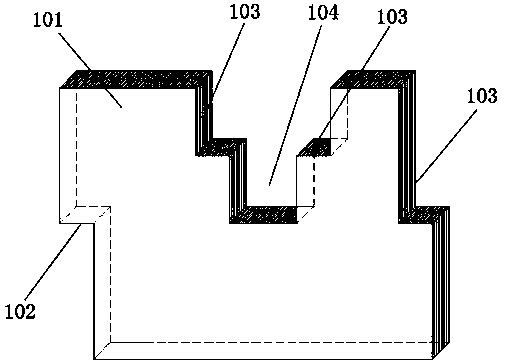

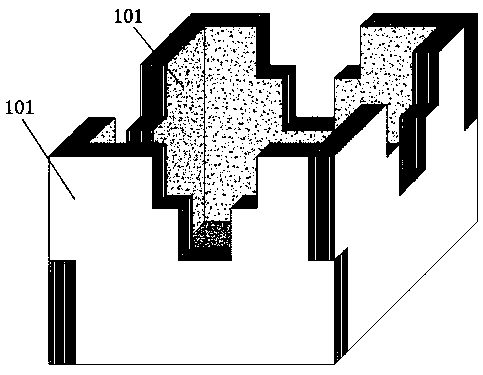

[0040] Such as Figure 1-10 As shown, a prefabricated assembly type membrane includes a platform membrane 1, a platform template 101, a second horse-tooth frame 102, a first horse-tooth frame 103, a pouring connection port 104, a transfer stack 105, and a beam membrane 2 , beam formwork 201, reserved hole 3, prefabricated bolt 4, beam end formwork 5, middle formwork 6, T-shaped support plate 7 and rectangular support plate 8.

[0041]The beam membrane 2 is arranged between the platform membranes 1, and the platform membrane 1 includes a set of platform templates 101. One end of the platform template 101 is provided with a first buttress 103, and the other end is provided with a second Ma Yacha 102, a group of cap formworks 101 are adjacent to each other to form a closed pouring space through the cooperation of the first mosaic cup 103 and the second mosaic cup 101, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com