High efficient improved wood preservation method

A high-efficiency technology for wood preservatives, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of slow drying speed of paint, large space required, lack of oiling machine anti-corrosion oil, general quality and effect, etc. Achieve the effects of improving oiling efficiency and anti-corrosion quality, improving practical performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

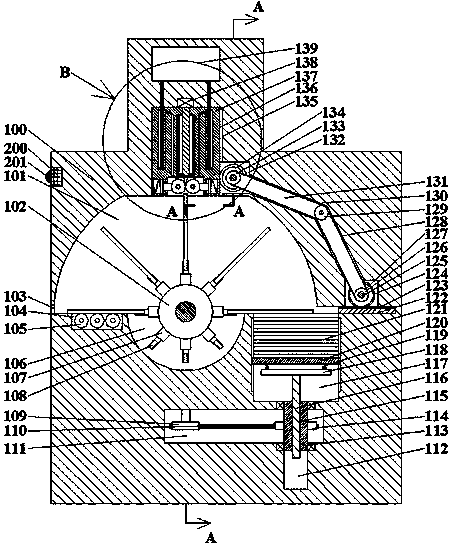

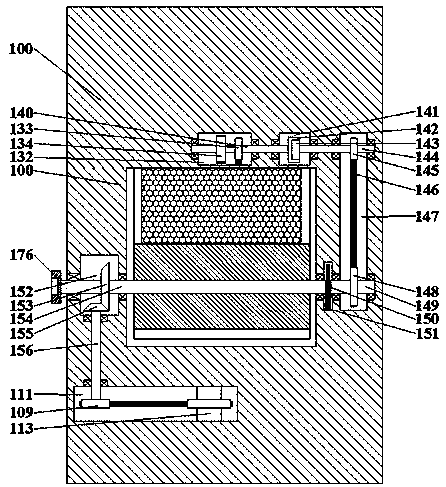

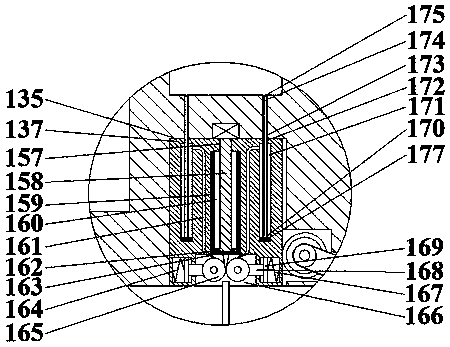

[0020] like Figure 1-Figure 3 As shown, the improved high-efficiency wood preservative equipment of the present invention includes a fuselage 100, a first cavity 101 arranged in the fuselage 100, and a first transmission cavity 111 arranged in the fuselage 100. A second cavity 135 with a downward opening is provided in the top wall of the first cavity 101, and a third cavity 106 with an upward opening is provided in the bottom wall of the first cavity 101, and the left side of the third cavity 106 A fourth cavity 104 communicating with the first cavity 101 is provided in the end wall, and a fifth cavity 117 communicating with the first cavity 101 is provided in the right end wall of the third cavity 106 , a second transmission cavity 147 is arranged in the front end wall of the first cavity 101, and a third transmission cavity 152 is arranged in the rear end wall of the first cavity 101. A sixth cavity 151 is disposed between the second transmission cavity 147, and a first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com