Fabricating method of all-ceramic preformed crown basic set

A manufacturing method and technology of prefabricated crowns, applied in the field of oral restoration, can solve problems such as compression of gingiva, long clinical time-consuming of prefabricated crowns, incomplete placement of prefabricated crowns, etc., achieve high accuracy, reduce labor costs, and ensure quality The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

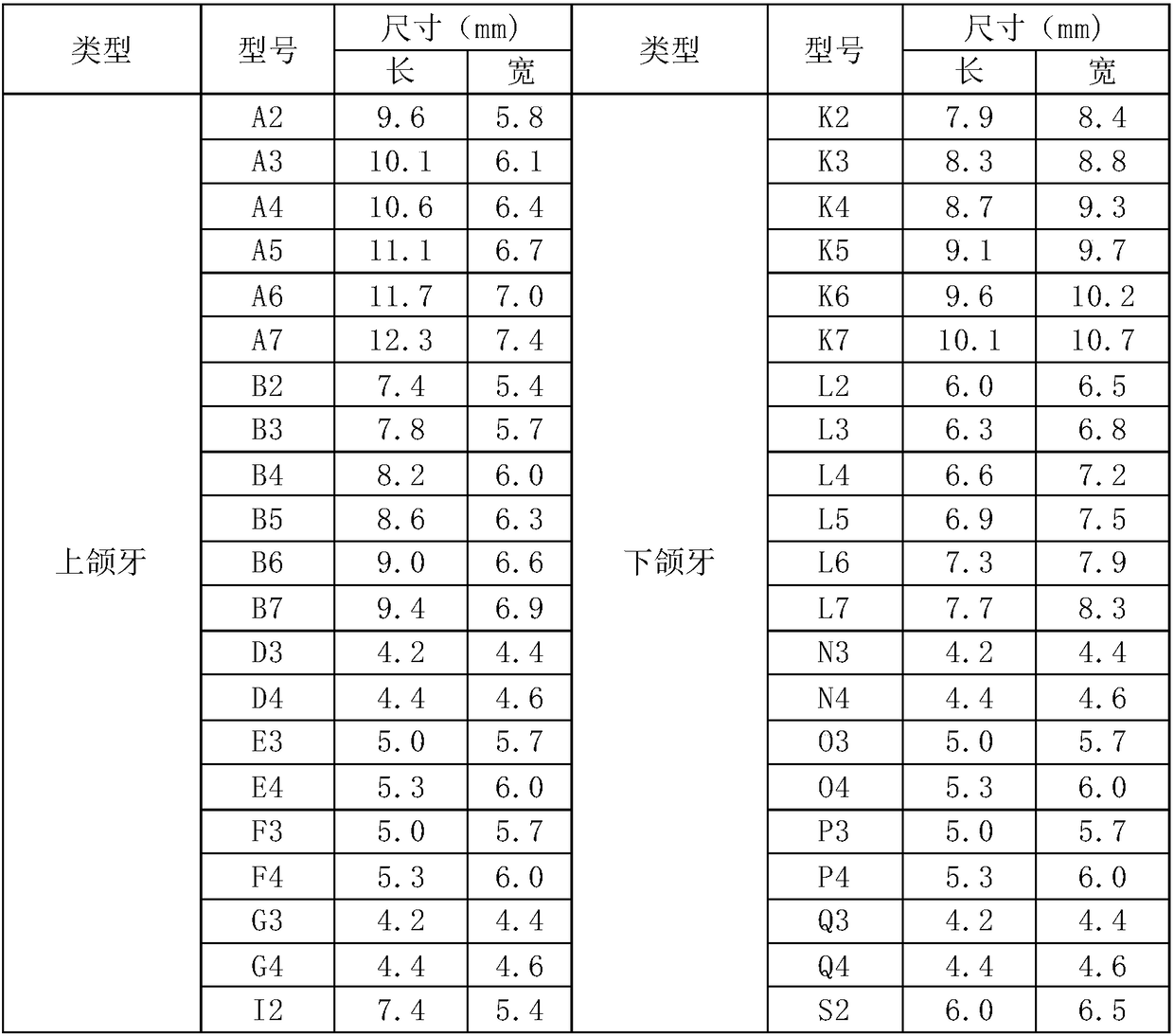

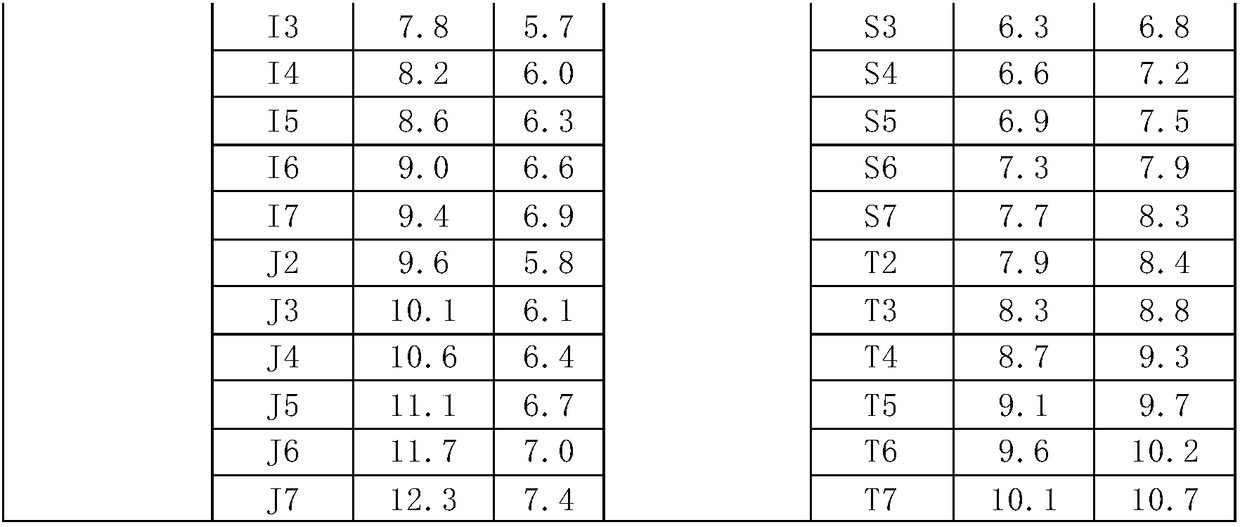

[0017] 1) Design the size of the all-ceramic prefabricated crown set according to the data in Table 1, where the thickness of the all-ceramic prefabricated crown is 5mm, and then use the computer for typesetting;

[0018] 2) Select the zirconia material according to the color of the deciduous teeth and cut out the zirconia crown according to the design in step 1);

[0019] 3) Soak the zirconia crown in the dyeing agent for 20 seconds;

[0020] 4) Sintering the zirconia crown in a sintering furnace for 4 hours at a temperature of 1500-1550 degrees;

[0021] 5) Grinding and trimming the zirconia crown;

[0022] 6) Glaze the outside of the zirconia crown and sinter at 800-890 degrees for 10 minutes;

[0023] 7), quality inspection shipments.

[0024] Table 1 Model list of all-ceramic prefabricated crowns

[0025] Remarks: The size is described as (length * width) (mm), tolerance ± 0.3mm

[0026]

[0027]

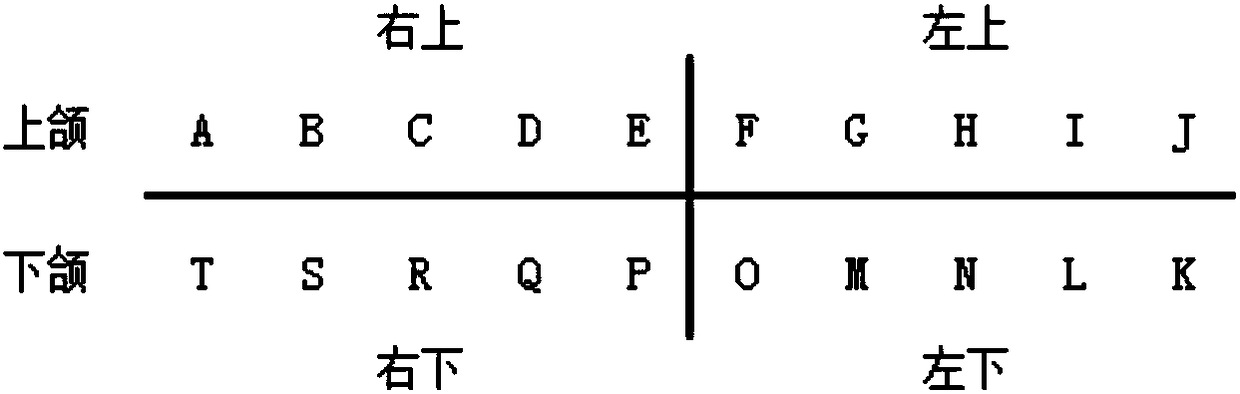

[0028] The arrangement order of the numbered crowns in Table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com