An idc non-stripping wiring device

A wiring device and stripping-free technology, which is applied in the direction of connection, conductive connection, electrical components, etc., can solve the problem of large wire diameter and large operating force of stripping-free connection, and achieve the advantages of avoiding adverse effects, convenient wiring, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

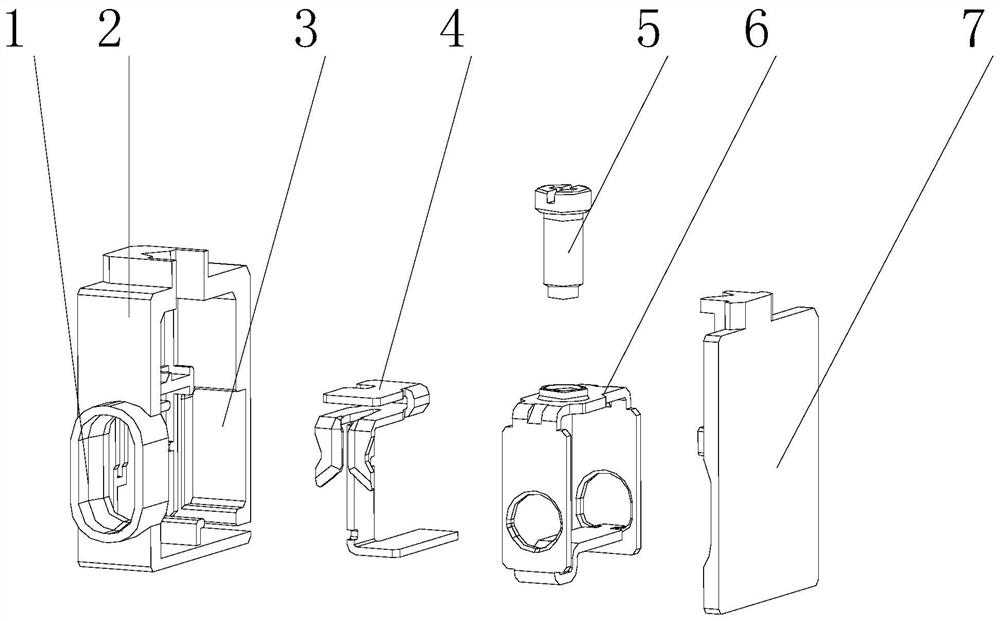

[0033] Example 1: See Figure 1-Figure 3 , Figure 5-Figure 8 , the first technical solution of the present invention is: an IDC non-stripping wire connection device, including a mounting housing, a switch knife conductive strip 4, a clamping body 6 and a driver;

[0034] The installation housing is a rectangular housing structure, which is snapped together by the right housing 2 and the left housing 7; the front wall of the installation housing is provided with a through waist-shaped long hole 1, and the installation A stop groove 3 is provided on the inner side of the rear wall of the housing, and the stop groove 3 is opposite to the elongated hole 1;

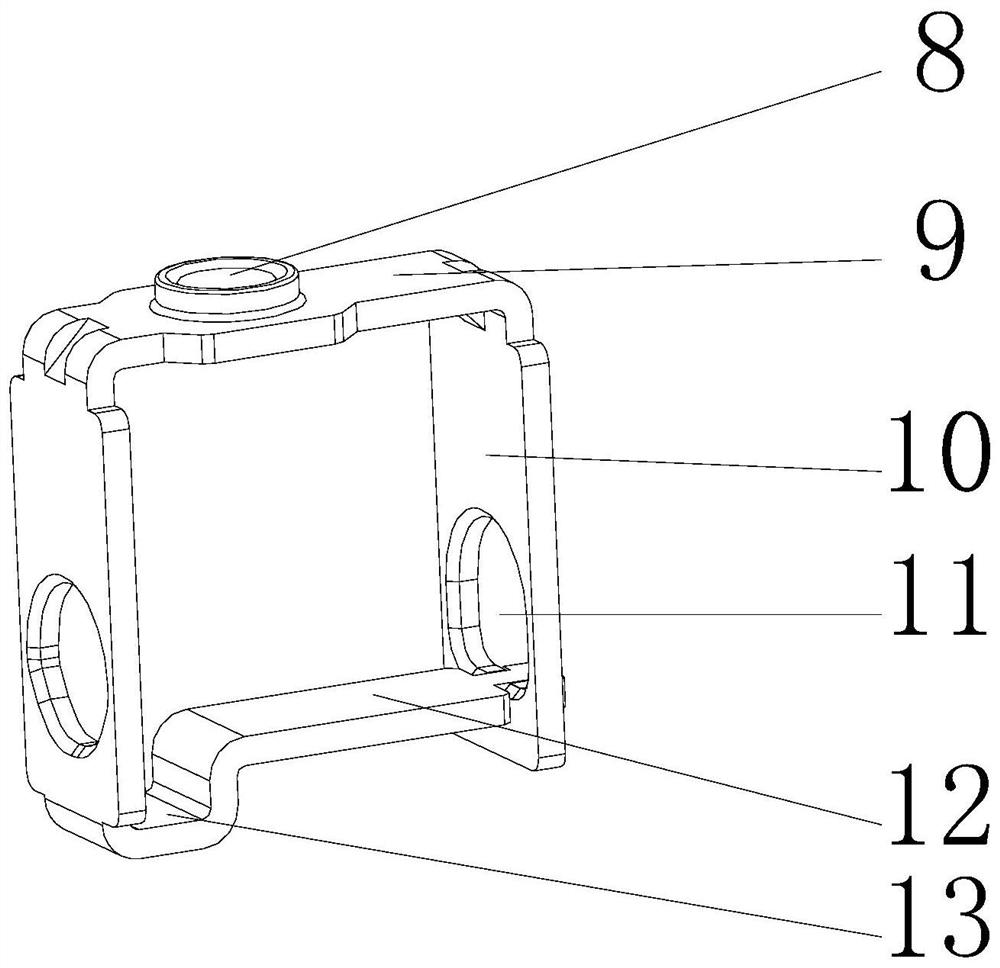

[0035] The clamping body 6 is a frame structure, including: front and rear side plates 10, a bottom plate, and a top plate 9; the front and rear side plates 10 of the clamping body 6 are respectively provided with wire through holes 11, and the wires pass through The inner diameter of the hole 11 is equal to or slightly lar...

Embodiment 2

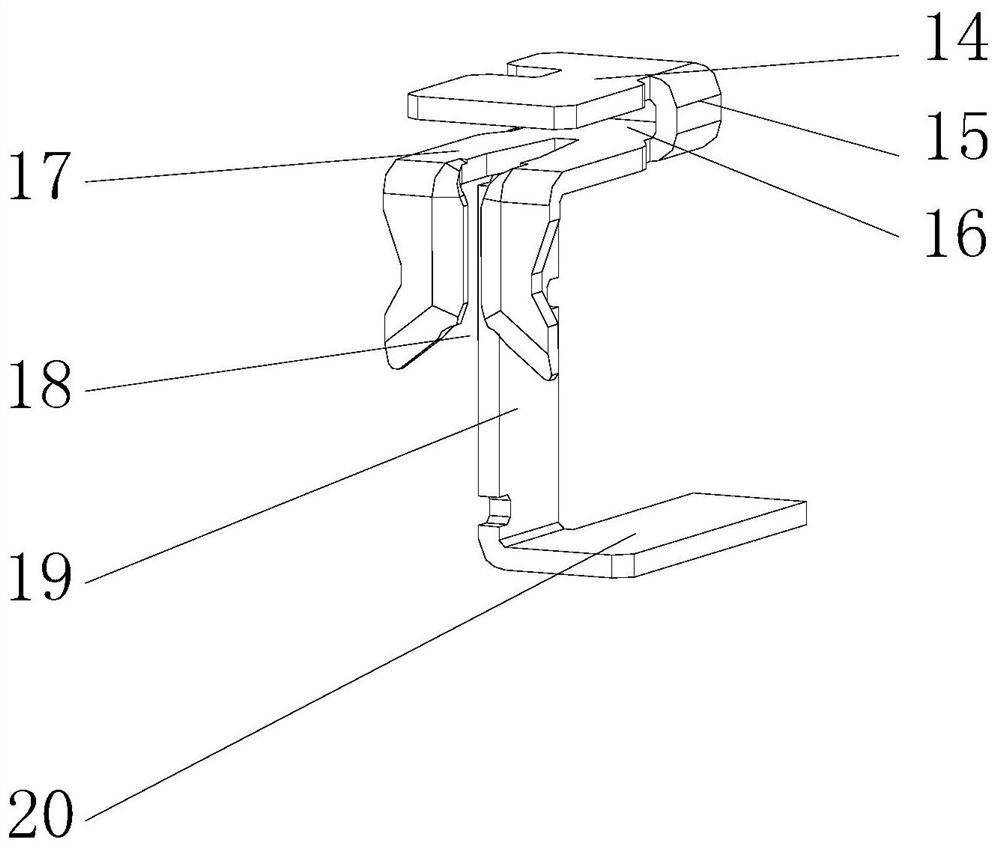

[0039] Embodiment 2: Please refer to the second technical scheme of the present invention Figure 1-Figure 2 , Figure 4-Figure 8 ; The main difference between the second technical scheme and the first technical scheme is the difference in the structure of the switch knife conductive strip 4:

[0040] In the second technical solution, the switch knife conductive strip 4 comprises a switch knife conductive strip main body and a knife edge 18 fixedly connected to the switch knife conductive strip main body; 1. The supporting conductive strip 19 and the top conductive strip 16 are formed, and the same sides of the bottom conductive strip 20 and the top conductive strip 16 are horizontally connected to the upper and lower ends of the supporting conductive strip 19 respectively;

[0041] The two conductive strips forming the knife edge 18 are respectively fixedly connected to the supporting conductive strip 19 and the top conductive strip 16 through two vertical connecting plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com