An anti-interference sub-pixel line fitting method

A straight line fitting, sub-pixel technology, applied in the field of anti-interference sub-pixel straight line fitting, can solve the problems of insufficient pixel-level edge detection accuracy, poor anti-interference ability, low pixel-level line detection accuracy, etc., and achieves strong configurability. strong anti-interference ability and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

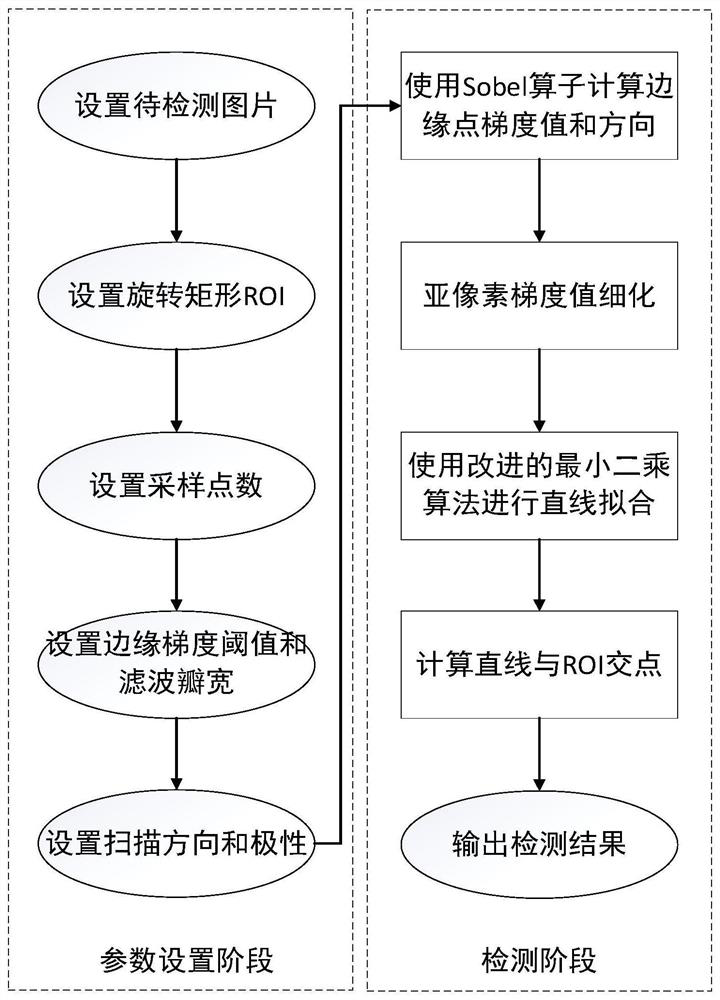

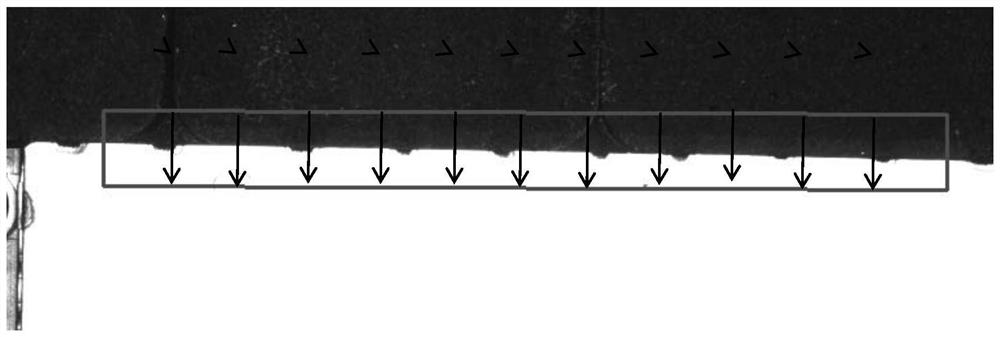

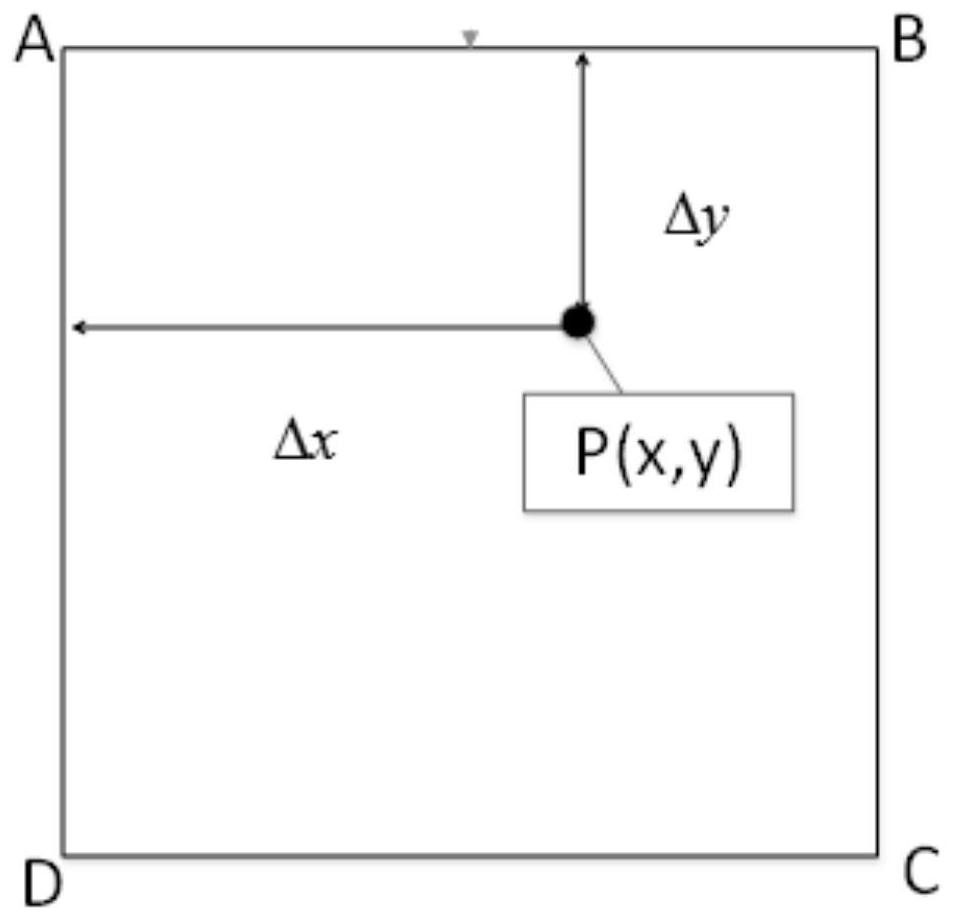

[0059] In order to solve the problems of low accuracy and poor anti-interference ability of traditional pixel-level line detection, the present invention proposes an anti-interference sub-pixel line fitting method, the process of which can be found in figure 1 , set the ROI of the image, and set the detection information for edge point detection. According to the set detection information, use the Sobel operator and neighborhood weighting to calculate the edge gradient value and angle value of the scanning point, and then use the filter lobe width parameter Further reduce the influence of noise points, record the scan points whose gradient value and angle value meet the requirements, perform quadratic curve fitting on the scan points that meet the requirements, and take the extreme point of the quadratic curve as the edge point of the candidate line; then use The straight line fitting algorithm based on the distance weight of the edge point performs multiple iterative fitting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com