Cyclic hydrodynamic pipeline fracture simulation experiment apparatus and cyclic hydrodynamic pipeline fracture simulation experiment method

A technology of simulating experimental equipment and circulating water, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of consuming a lot of manpower, material resources, extremely high loading capacity requirements, and dangerous experiment processes, and achieve saving Space, increased utilization, and reduced work risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

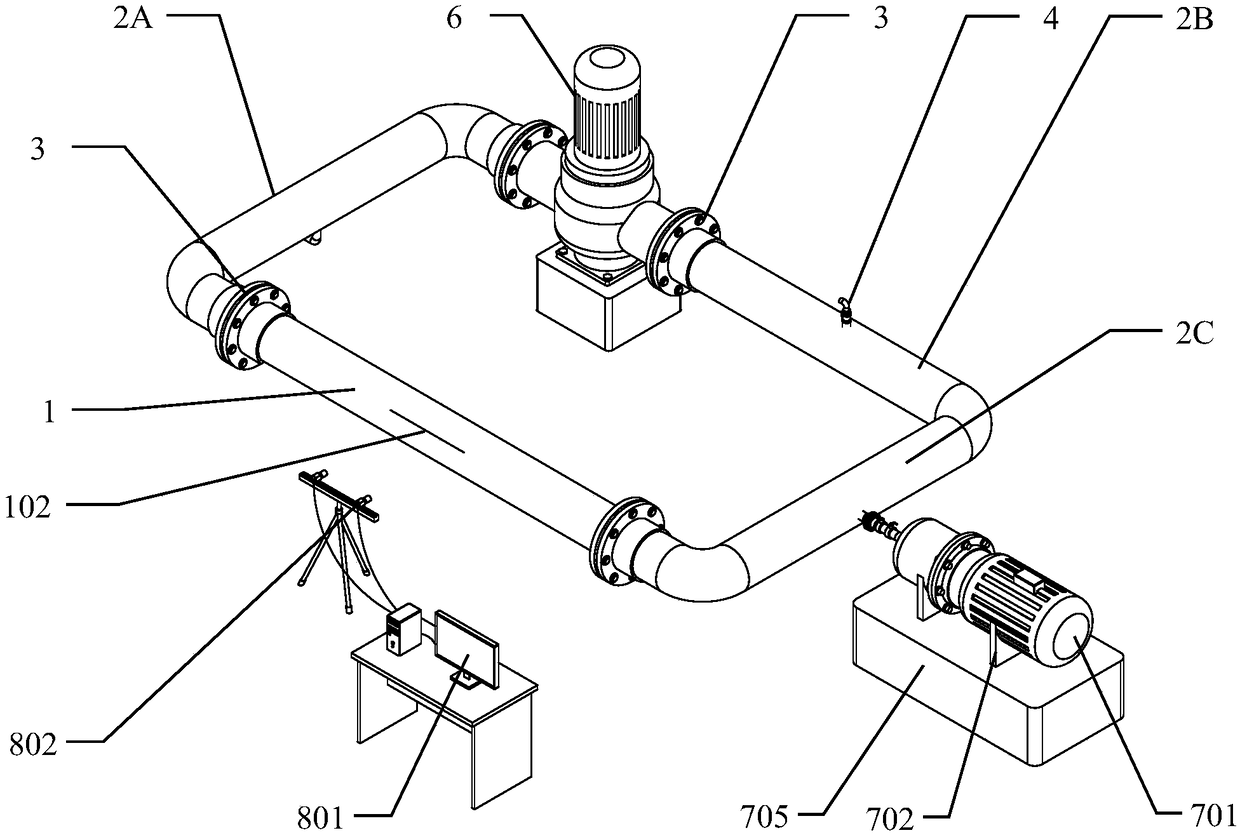

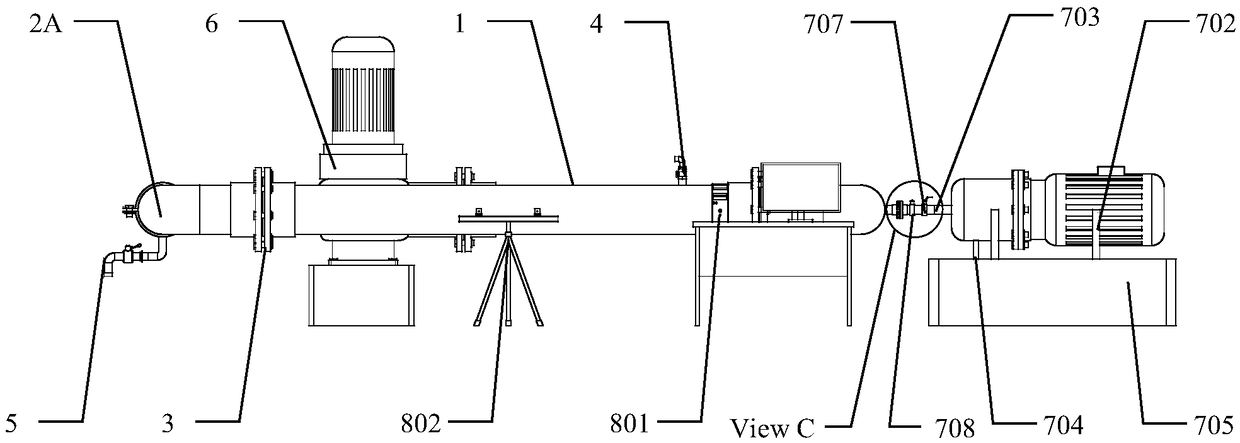

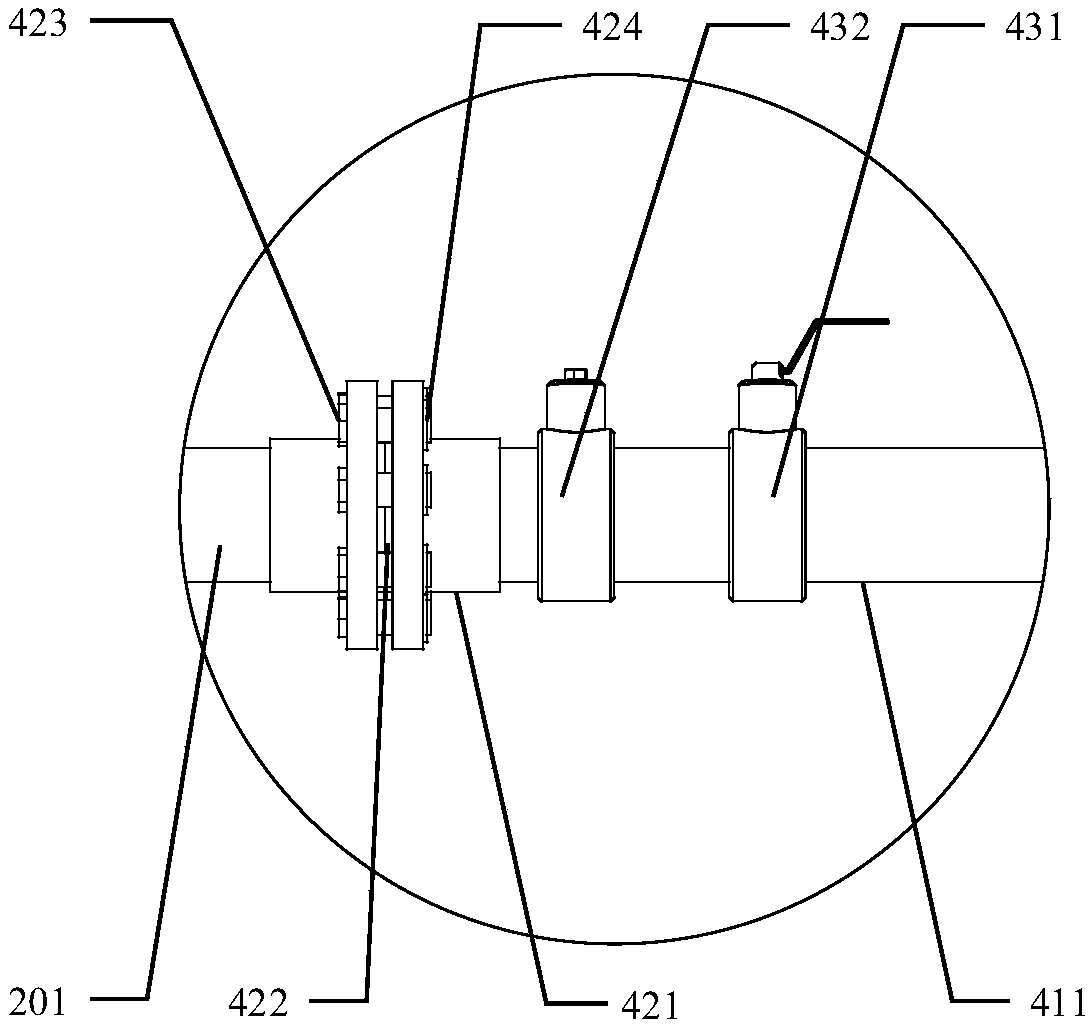

[0020] Such as Figure 1 to Figure 6 As shown, the circulating hydrodynamic pipeline fracture simulation experiment device includes: experimental pipe section 1, left connecting pipe section 2A, rear connecting pipe section 2B, right connecting pipe section 2C, electric circulation pump 6, booster system 7, DIC test system 8; Among them, the experimental pipe section 1, the left connecting pipe section 2A, the electric circulation pump 6, the rear connecting pipe section 2B, and the right connecting pipe section 2C are sequentially connected end to end through the flange 3 to form a closed-loop piping system; the pressurization system 7 is set in The right side is connected to the right side of the pipe section 2C, which transmits fluid into the device and increases the pressure inside the device, causing the experimental pipe section 1 to break; the DIC test system 8 is placed directly in front of the experimental pipe section to observe the crack growth process of the experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com