Paste filling material laboratory curing method for simulating actual stope environment

A paste filling and laboratory technology, applied in the field of paste filling mining, can solve problems such as differences, and achieve the effect of ensuring consistency, overall stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

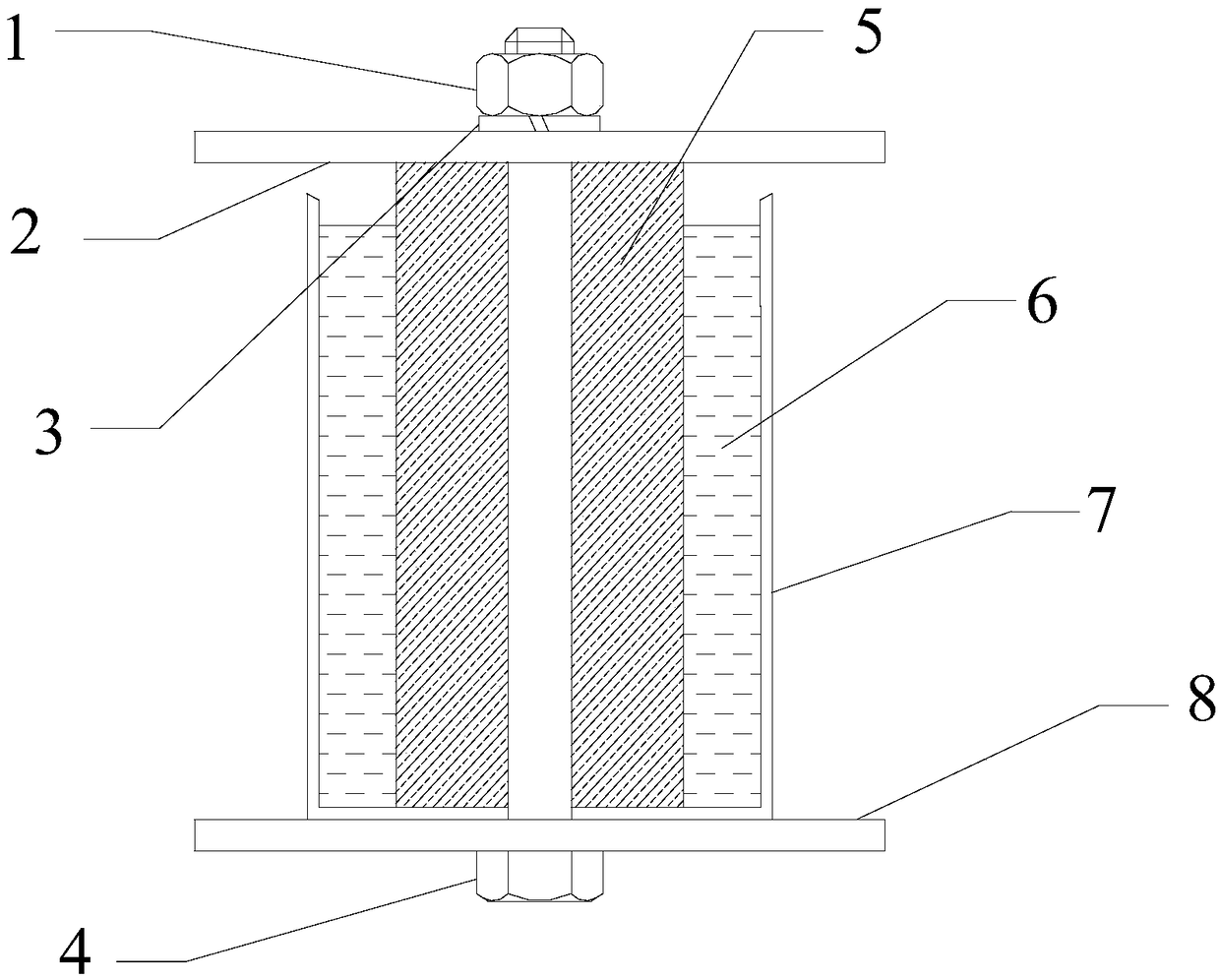

Image

Examples

Embodiment 1

[0049] The metal mine adopts the open-stop mining method in sections, and uses the whole tailings paste filling method to deal with the goaf in the later stage. One of the gobs has a size of 5m (width) × 22m (length) × 26m (height). The required full tailings paste filling body is transported to the goaf by pumping through the delivery pipeline for filling;

[0050] Conduct on-site investigations on the actual stope. After the paste filling is completed, the actual stope temperature, humidity, stress on the filling body, mine water level and CO 2 Concentration is monitored in real time, and the chemical composition of mine water is detected at the same time;

[0051] During real-time monitoring, the temperature, humidity, stress on the filling body, mine water level and CO are recorded every 1 hour. 2 Concentration value, the average value of all values within 24h is used as the basis for setting the indicators of prefabricated maintenance;

[0052] Prepare the filling bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com