Dust collector compressed air leakage alarming method

A technology of compressed air and leakage alarm, which is applied to alarms, instruments, and liquid/vacuum measurement for liquid tightness. The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

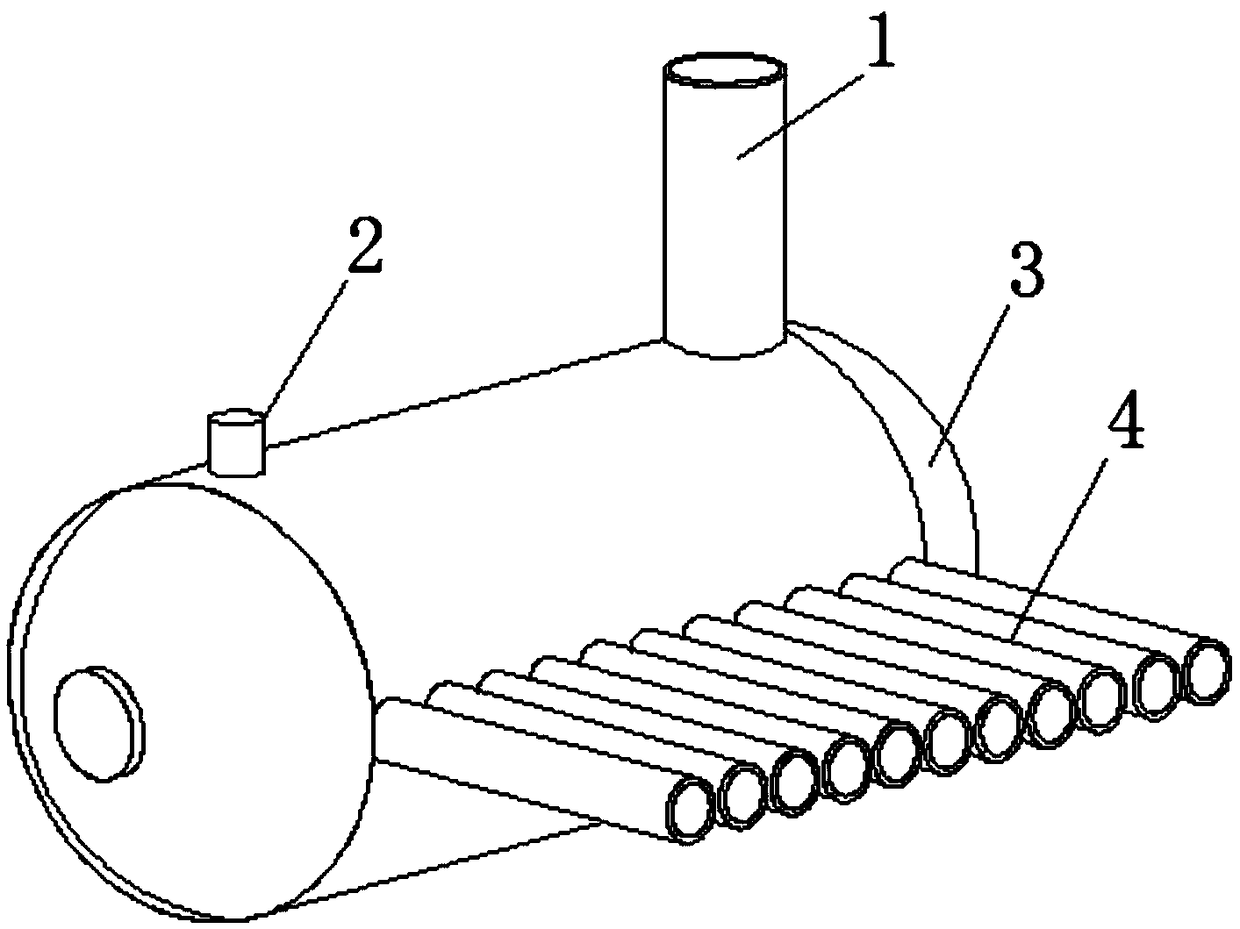

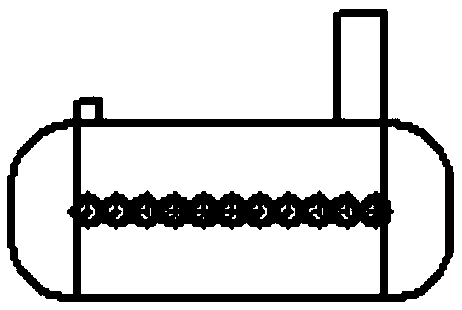

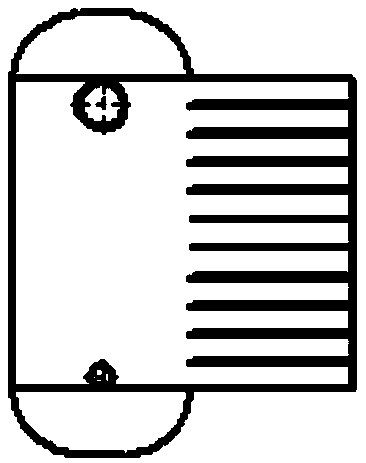

[0030] After the system is initialized, the compressed air intake pipe 1 on the air bag 3 is connected to the compressed air pipeline; the compressed air enters the air bag 3, and the air bag 3 is installed with a pressure sensor through the pressure sensor installation hole 2; The sensor is connected to the PLC analog channel through a shielded cable; the analog signal collected by the pressure signal is processed; based on the S7-400PLC pressure detection system, after the pressure sensor analog signal is processed, it is judged whether the compressed air is leaking in the PLC program; Whether the pressure signal is abnormal, if it is abnormal, the program will output an alarm signal to drive the alarm light on the electric cabinet to flash and the alarm bell will sound, and at the same time, the upper monitoring system will pop up an alarm message; if the system detects a compressed air leak, the equipment administrator will find it immediately and deal with it in time; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com