Leak determination on hydraulic clutch actuators

A clutch and actuator technology, applied in clutches, mechanical equipment, etc., can solve the problems of inaccuracy and inaccuracy of known methods of wear and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

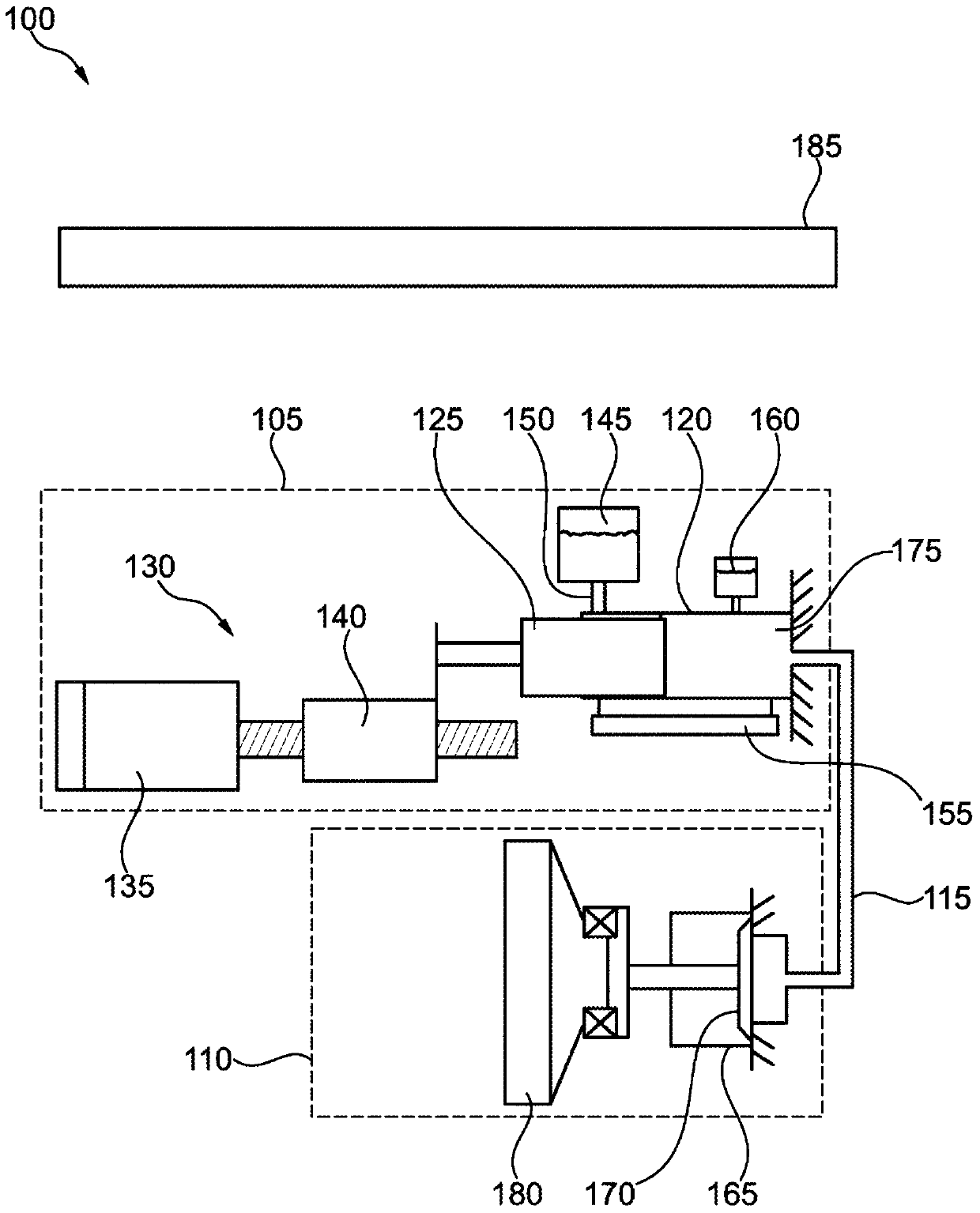

[0027] figure 1 A hydrostatic clutch actuator 100 is shown. Clutch actuator 100 includes a driving side 105 and a driven side 110 . The two sides are fluidically connected to each other by means of hydraulic lines 115 .

[0028] The active side 105 includes an active cylinder 120 which is closed by means of an active piston 125 . The active piston 125 can be moved axially in the active cylinder 120 by means of a drive 130 . The drive 130 generally includes an electric motor 135 , which is connected to the drive piston 125 by means of a switching mechanism 140 , wherein the switching mechanism 140 includes, for example, a screw drive.

[0029] In one embodiment, a compensating tank 145 is provided on the master cylinder 120 , which is filled with hydraulic fluid at ambient pressure. The connection opening 150 between the compensation container 145 and the master cylinder 120 is released by the master piston 125 when the master piston has moved far enough away from the maste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com