Natural circulation steam generation system and generation method for fused salt tower-type heat power generation

A technology of natural circulation and thermal power generation, which is applied in the steam generation method using heat carrier, steam generation, preheating, etc., can solve problems such as molten salt condensation, and achieve the effect of reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

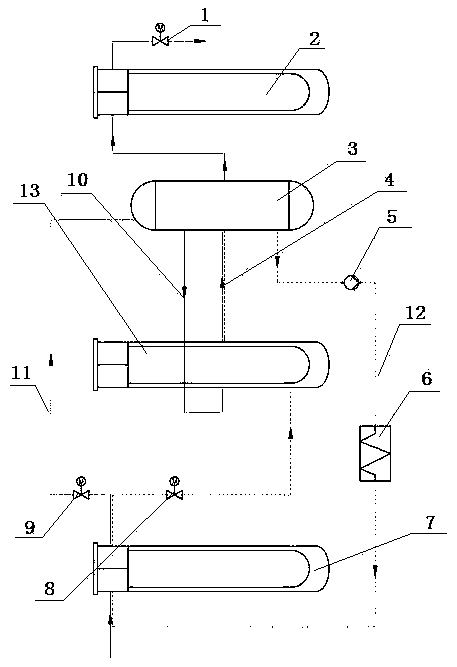

[0020] A natural circulation steam generation system for molten salt tower thermal power generation, which consists of: a circulation system 11 and a preheating system 12, said preheating system includes a circulating water pump 5 and a heater 6, and one end of said circulating water pump It is connected with the steam drum 3 through a pipeline, the other end of the circulating water pump is connected with the heater through a pipeline, and the heater is connected with the water supply end of the preheater 7 through a pipeline.

Embodiment 2

[0022] According to the natural circulation steam generation system for molten salt tower thermal power generation described in Embodiment 1, the circulation system includes the evaporator 13, the superheater 2, the steam drum and the preheater, and the The preheater is connected to the steam drum through valve A, part number: 9, the preheater is connected to the evaporator through valve B, part number: 8, and the evaporator is connected to the An ascending pipe 4 and a descending pipe 10 are arranged between the steam drums, and the steam drum is connected to the superheater through pipelines, and a valve C, part number: 1, is arranged on the superheater.

Embodiment 3

[0024] A generation method of a natural circulation steam generation system for molten salt tower thermal power generation, the method comprising the following steps:

[0025] (1) Preheating process;

[0026] Close valve A and open valve B, open valve C to a certain degree, turn on the heater and circulating water pump, the feed water passes through the preheater, passes through valve B to the evaporator, and passes through the rising pipe of the evaporator to the steam drum, and the water in the steam drum is The circulating water pump enters the heater for heating, and the heated water passes through the preheater, evaporator and steam drum to generate saturated steam, and the generated saturated steam enters the superheater, the system pressure gradually increases, and finally the saturated temperature is raised to the point where the molten salt can pass Enter the temperature to complete the preheating process;

[0027] (2) Cycle process;

[0028] Close the circulation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com