Heat source-less independent starting method of cold start oil auxiliary heating system of boiler generating set

A cold start-up and auxiliary heating technology, which is applied in the control system, combustion method, lighting and heating equipment, etc., can solve the problems of increasing start-up costs, increasing start-up boiler room construction funds, etc., and achieve the effect of reducing operating costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

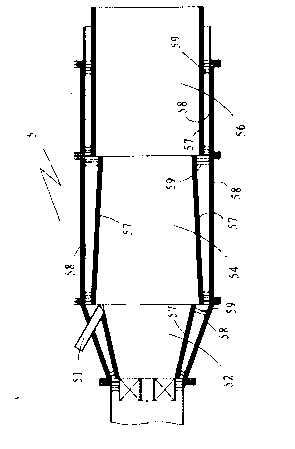

[0035] The patent of the present invention will be further described below with reference to the accompanying drawings in conjunction with the embodiments, so that those skilled in the art can better understand the patent of the present invention and implement it, but the examples given are not intended to limit the present invention.

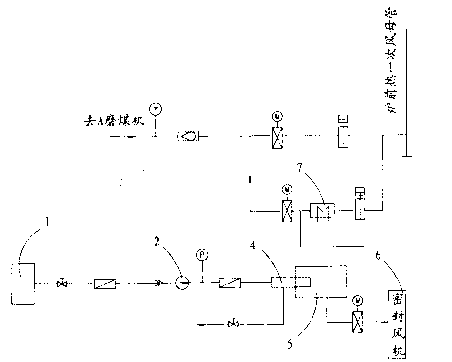

[0036] The external heat source required for the cold start of the boiler is mainly to meet the steam demand of hot air pulverization of coal mill, soot blowing of boiler air preheater, thermal deoxygenation of feed water, steam for turbine shaft seal, and running of steam-driven feed water pump, etc. . Considering that the amount of ash in the initial stage of the boiler is very small, the compressed air used for ash transportation has a capacity of 80Nm3 / h, and the ash transportation gas source of the economizer can be connected with the soot blowing steam pipeline of the air preheater through the stop valve to provide soot blowing of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com