Compensation sealing valve seat

A technology for sealing valves and valve seats, which is applied to valve devices, cocks including cut-off devices, engine components, etc., which can solve problems such as leakage of sealing pairs, and achieve the effect of increasing the amount of wear and improving the ability to prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

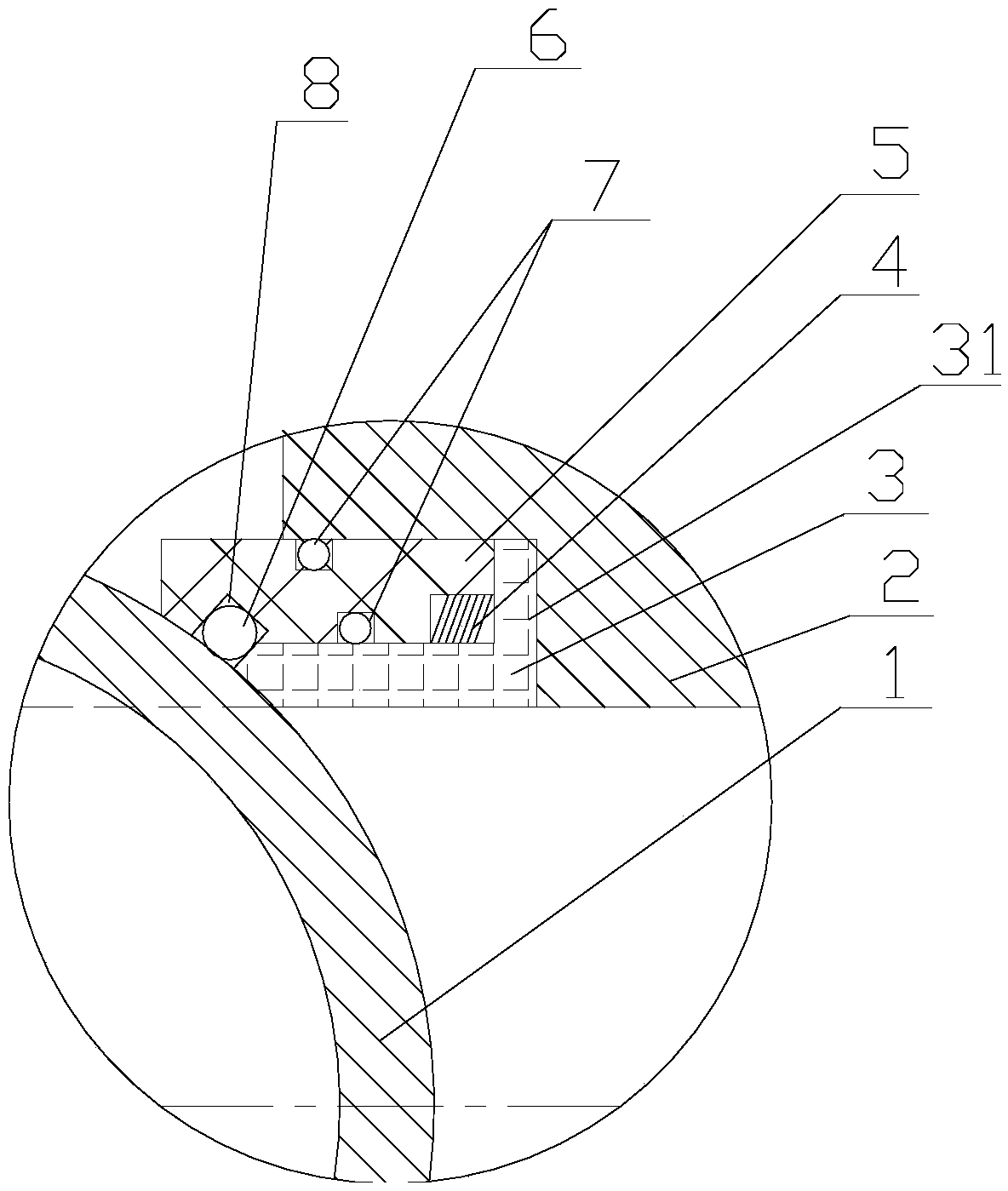

[0020] Such as Figure 1~2 As shown, the compensating sealing valve seat includes an inner ring 3 and an outer ring 5 , the inner ring 3 has a shoulder 31 at an end close to the valve body 2 , and the circumferential direction of the shoulder 31 is connected to the valve body 2 through threads. The outer ring 5 is sleeved on the inner ring 3, and the inner side of the outer ring 5 which is in contact with the inner ring 3 has a circumferential groove, and a compensating spring 4 is arranged in the circumferential groove, and the two ends of the compensating spring 4 Contact the outer ring 5 and the inner ring 3 respectively. In this embodiment, the compensating spring 4 is a disc spring; The fit shape, the fit between the outer ring 5 and the valve core 1 constitutes a first sealing pair, and the fit between the inner ring 3 and the valve core 1 constitutes a second seal pair. In this embodiment, both the first sealing pair and the second sealing pair are rigid seals, that is...

Embodiment 2

[0024] Similarly, a gasket is provided between the end surface of the shoulder 31 and the valve body 2 to prevent the fluid from entering between the shoulder 31 and the valve body 2 into the compensating spring 4 and causing the compensating spring 4 to fail due to corrosion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com