Adjustment structure of hob installation position for full-face hard rock tunnel boring machine

A tunnel boring machine and structure adjustment technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problem that the installation height of the hob cannot be adjusted according to specific conditions, the installation height of the hob cannot be adjusted, and the wear of the TBM hob is limited etc., to avoid eccentric wear, shorten construction time, and increase the wearable amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

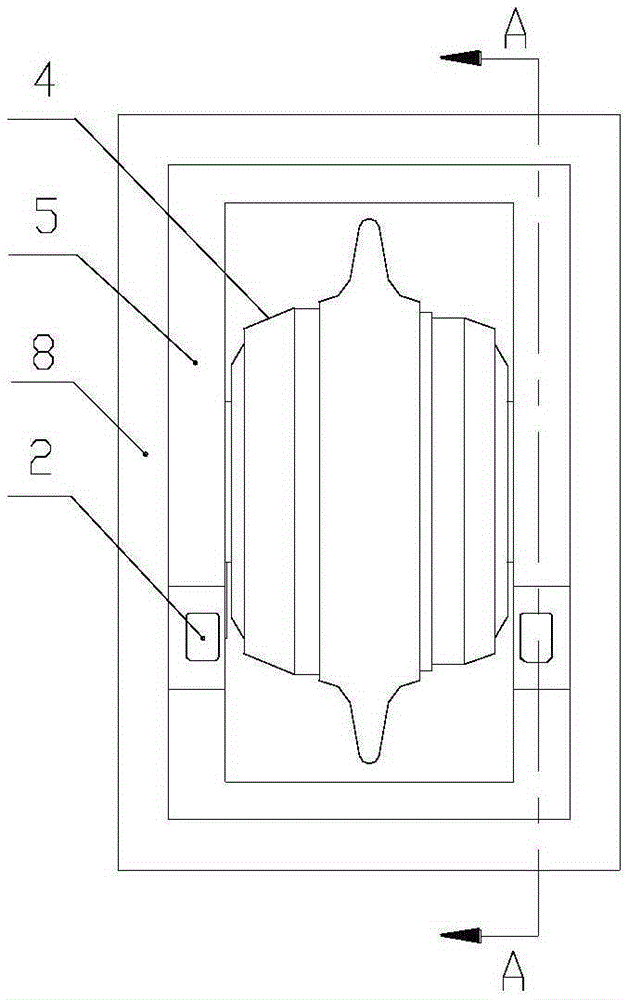

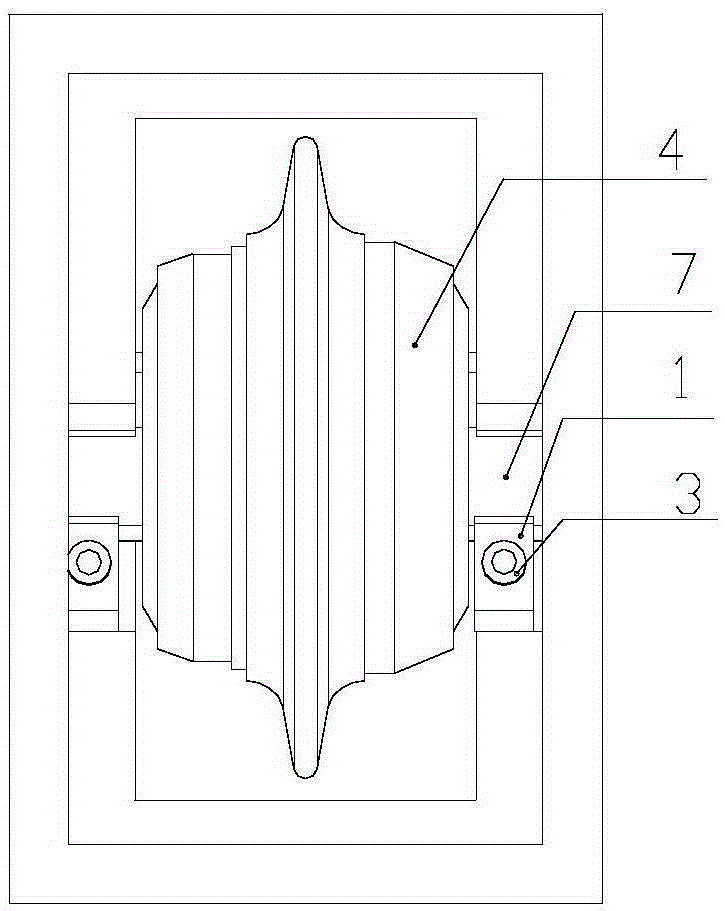

[0016] see Figure 1 ~ Figure 4 , a hob installation position adjustment structure for a full-section hard rock tunnel boring machine, comprising a hob support mandrel 6 and a support seat 5 thereof, the support seat 5 is fixed in the cutterhead mouth 8, and the support seat 5 is There are two supporting side plates 5-1 respectively corresponding to the two ends of the hob supporting mandrel 6, and each of the two supporting side plates 5-1 supports one of the hob supporting mandrel 6 The two ends of the hob supporting mandrel 6 are respectively connected to the supporting side plate 5-1 at the corresponding end through a mounting block 7, and the hob supporting mandrel 6 interferes with the mounting block 7 In cooperation, the mounting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com