Milling roller for roller mill,

The technology of a roller mill and grinding roller is applied in the field of grinding rollers for roller mills, which can solve the problems of low utilization rate of wear-resistant materials, low grinding efficiency, unreasonable structure, etc., so as to achieve long service life and improve grinding efficiency. , the effect of low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

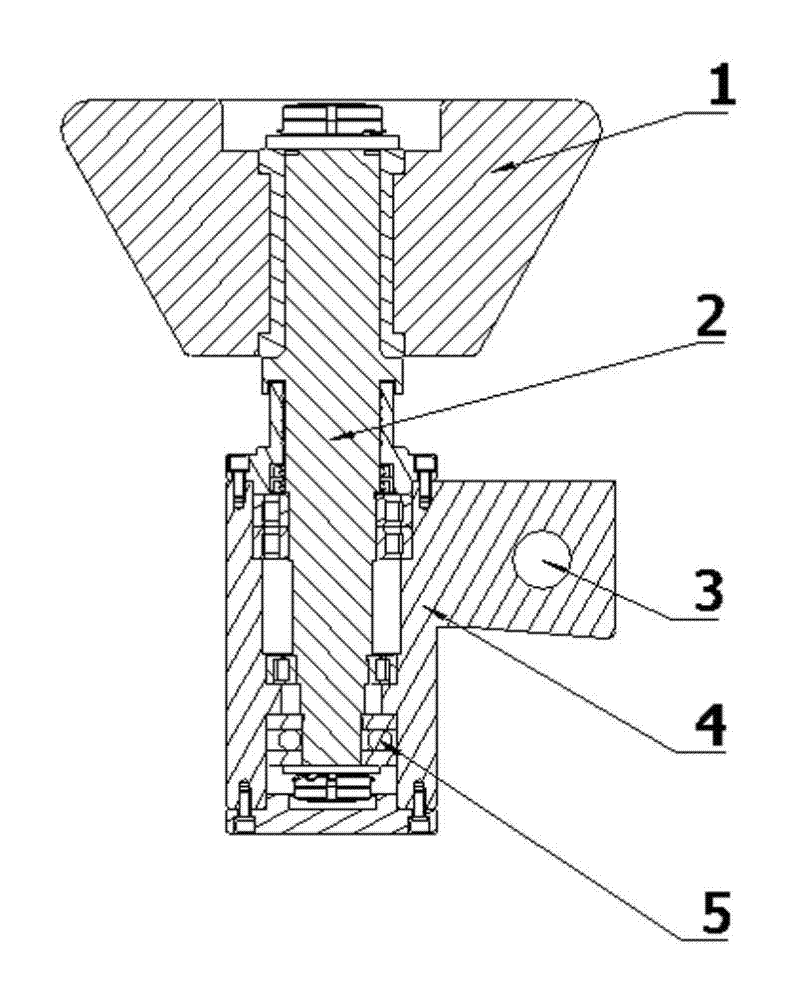

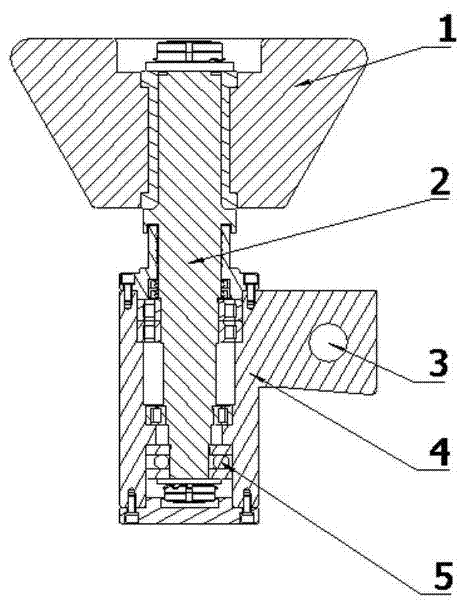

[0010] refer to figure 1 , this embodiment includes a roller shaft 2, the upper end of the roller shaft 2 is fixedly connected to a roller sleeve 1, the cross section of the roller sleeve 1 is in the shape of an inverted frustum, and its shape is like the flame of a torch, and the roller sleeve 1 is a wear-resistant medium; The lower end of the shaft 2 is sleeved with a bearing sleeve 4 with a hinge ear 3, and a bearing 5 is arranged between the bearing sleeve 4 and the roller shaft 2; the outer shape of the roller shaft 2 is like a handle of a torch.

[0011] The torch-shaped grinding roller of the present invention can maximize the wearable amount in a limited space; reduce the difficulties caused by machining of high-hardness wear-resistant materials; can withstand frequent vibrations and large axial forces, and is flexible in operation. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com