Combined rock debris cleaning tool with positively and reversely spiral blades

A technology of anti-helical blades and helical blades, which is applied in the field of forward and reverse helical blade combined cuttings cleaning tools, can solve the problems of low cleaning efficiency of wellbore cuttings, achieve improved cuttings cleaning efficiency, optimize upward return kinetic energy, and suppress Effects on the formation of debris beds and dunes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the present invention will be further described:

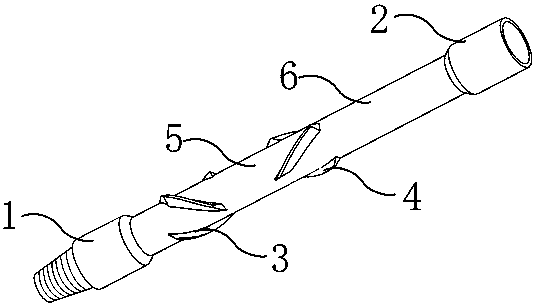

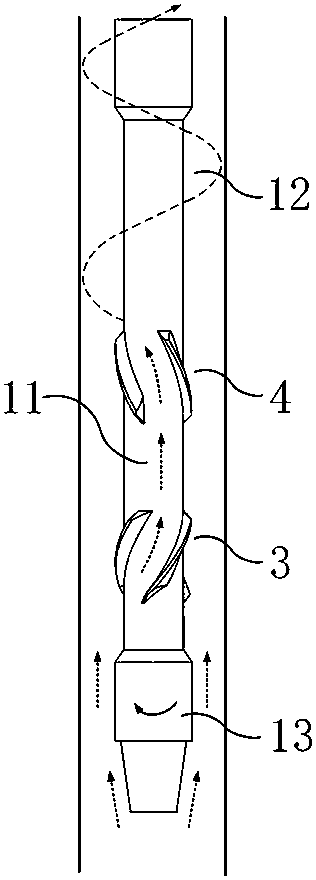

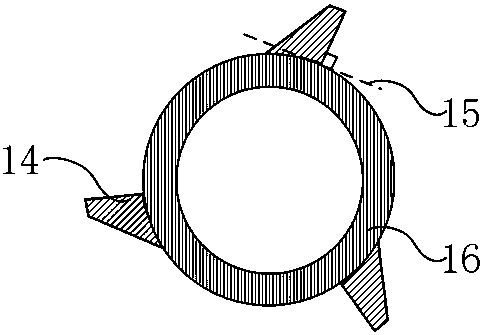

[0045] Such as figure 1 As shown, this combined forward and reverse spiral blade cuttings cleaning tool includes a body 16, the body 16 is a pipe body, the body 16 is provided with a forward spiral blade group and a reverse spiral blade group, and the upper end of the body 16 is provided with a female threaded joint 2, The lower end of the body 16 is provided with a male threaded joint 1, and the male threaded joint 1 and the female threaded joint 2 are used together with the drill pipe joint to connect the drill pipe. The male threaded joint 1 and the female threaded joint 2 can be machined from blanks, or can be connected to the body 16 by friction welding to ensure welding quality and connection strength. The forward helical blade 3 and the reverse helical blade 4 are both formed in cooperation with the body 16, and can be machined from a whole blank, or can be formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com