Vibrating roller unmanned driving system

An unmanned, roller compactor technology, applied in the direction of roads, road repair, roads, etc., can solve the problem that the unmanned driving technology has not matured application, does not consider the difference of unmanned driving on unmanned roads in the construction of water conservancy projects, It is difficult to achieve the ideal effect and other problems to achieve the effect of saving manpower, improving the level of construction quality and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples of implementation.

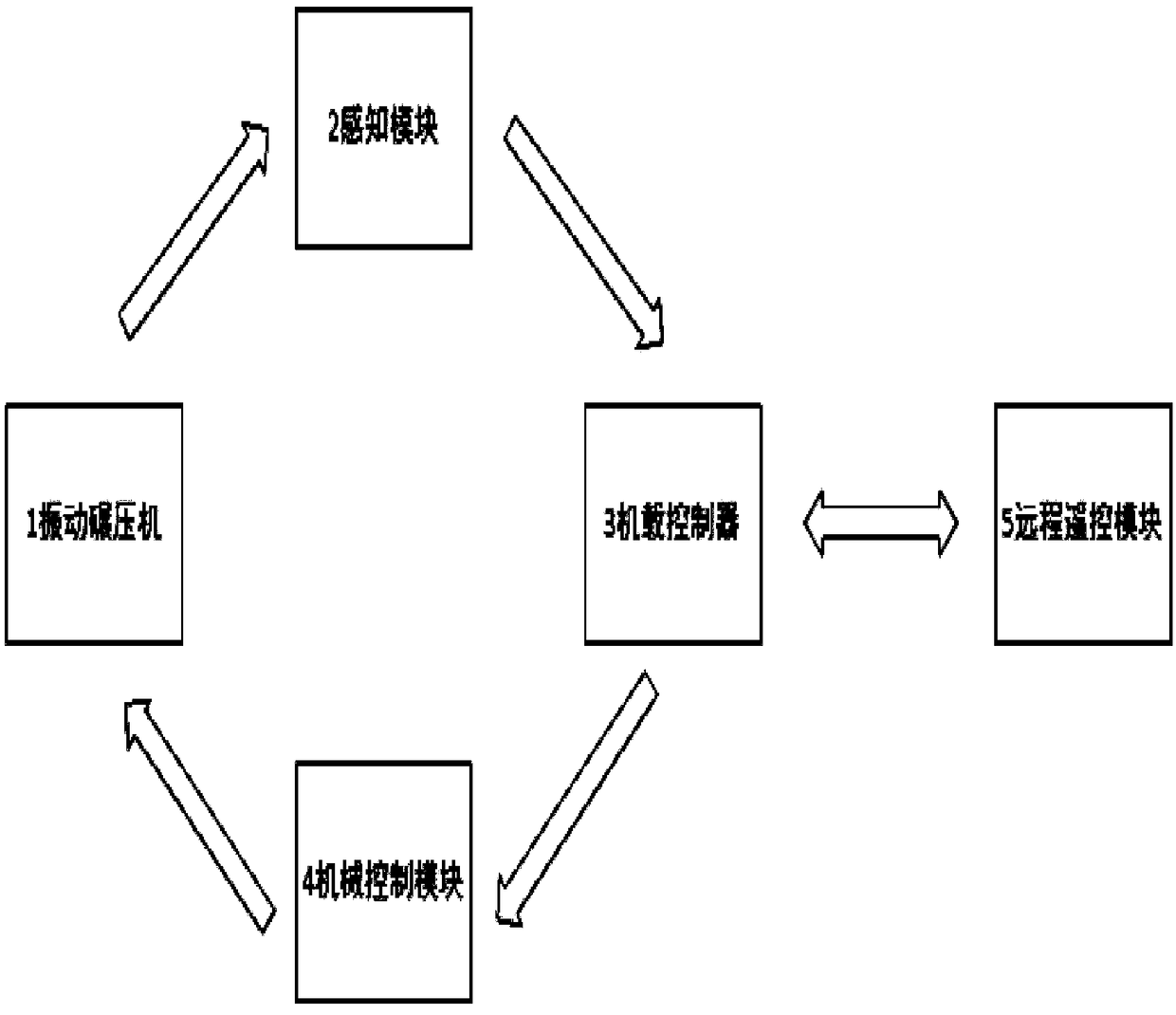

[0040] Such as figure 1The unmanned driving system of a vibratory roller includes: a vibratory roller, a perception module, an on-board controller, a mechanical control module, and a remote control module.

[0041] The vibratory rolling machine is the carrier of the unmanned driving system. The sensing module, on-board controller, and mechanical control module are mounted on the vibrating rolling machine; Surrounding obstacle detection information and real-time transmission of the data to the onboard controller; the onboard controller is used to analyze and process the data, send instructions to the mechanical control module, and communicate with the remote control module in real time; the mechanical control module passes the mechanical The device controls the operation of the vibration rolling machine; the remote co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com