an electric iron

A technology for an electric iron and a casing, applied in the field of electric irons, can solve the problems of generating more warm water vapor, affecting the user experience, scratching clothes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

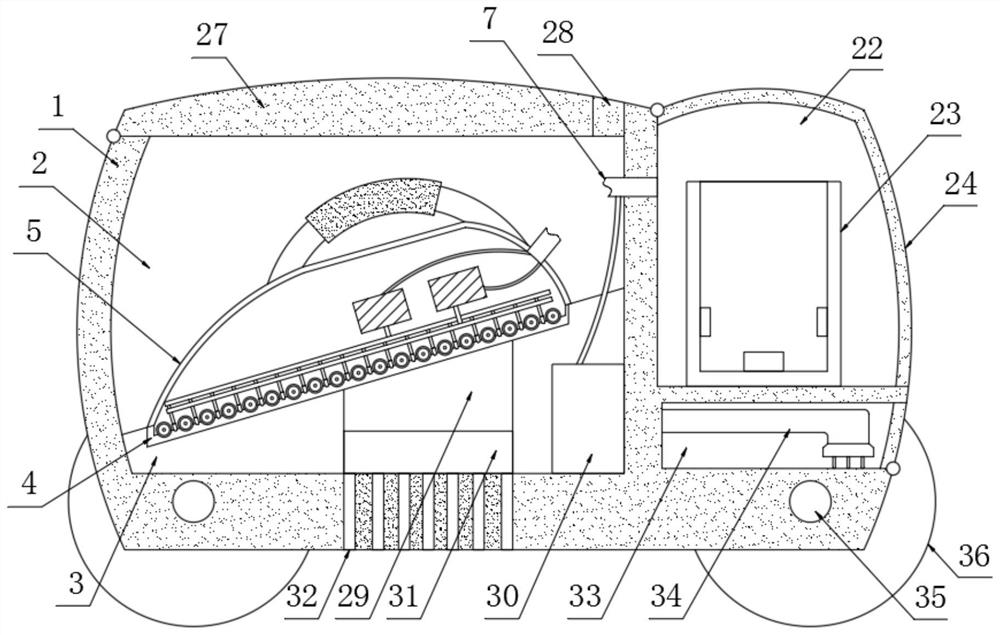

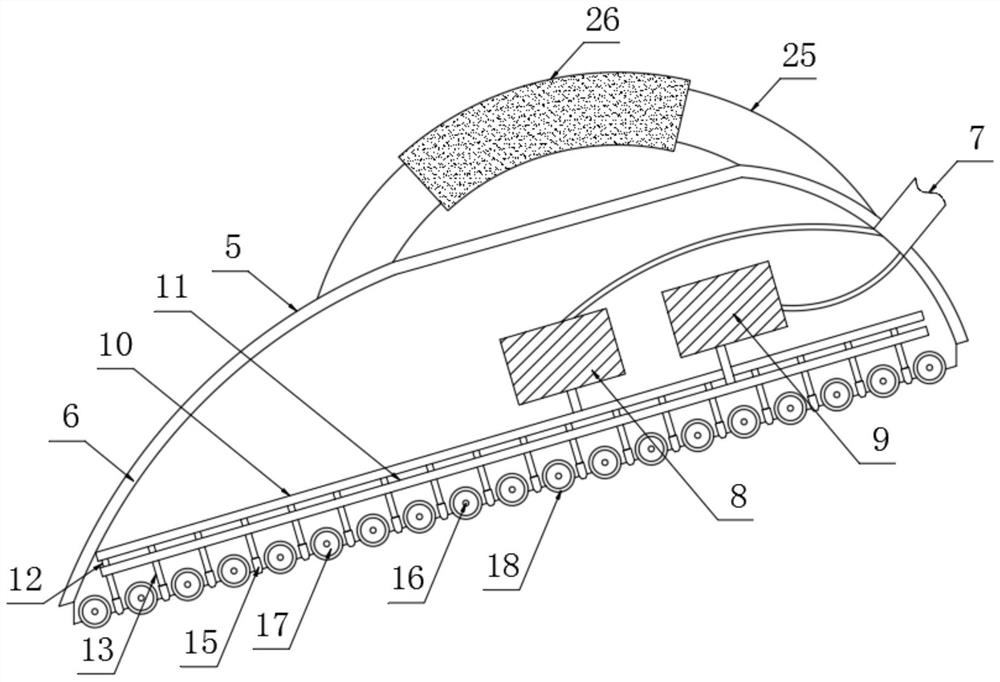

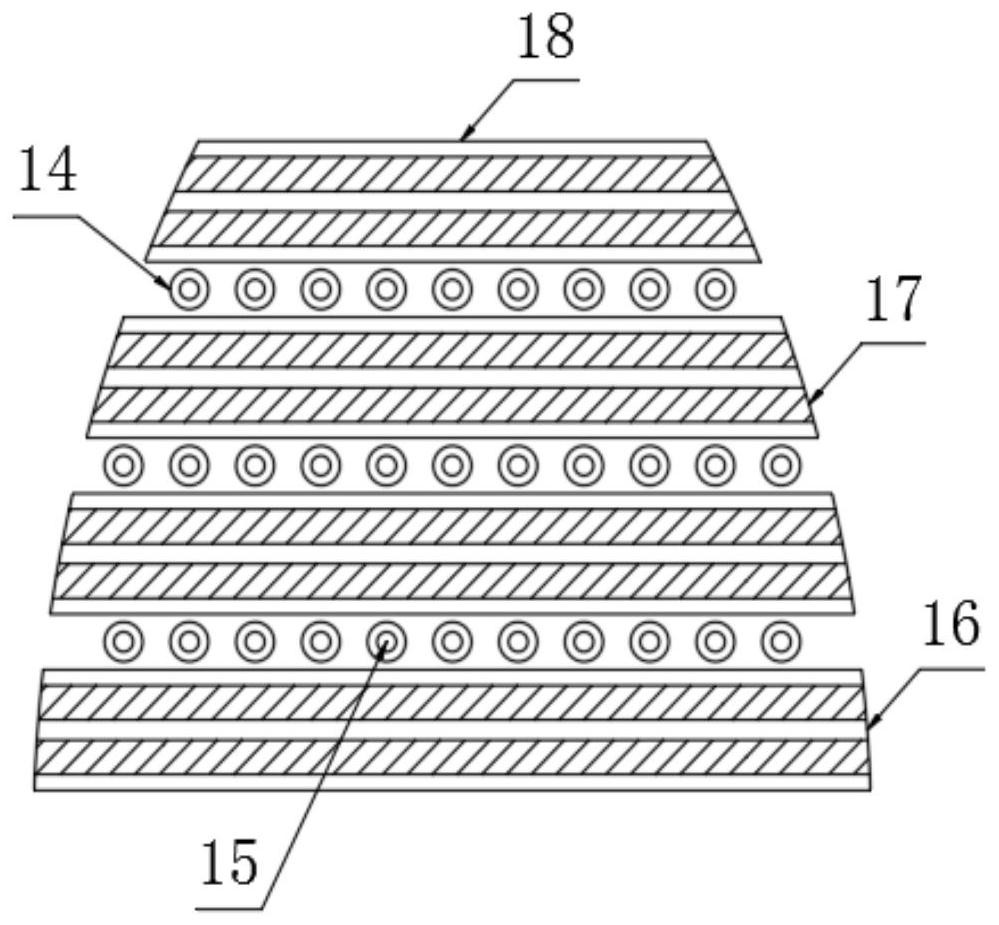

[0026] The present invention provides such Figure 1-4 The shown electric iron includes a first casing 1, a storage chamber 2 is provided inside the first casing 1, a placement seat 3 is provided inside the storage chamber 2, and a placement seat 3 is provided on the top of the placement seat 3. slot 4, the inside of the placement slot 4 is provided with an ironing mechanism 5, the ironing mechanism 5 includes a second casing 6, the side of the second casing 6 is provided with a connecting line 7 and a first fan 8 is provided inside With the second fan 9, the second fan 9 is located on the first fan 8 side, the connecting line 7 is provided with an exhaust pipe 19 and a steam outlet pipe 20, and the exhaust pipe 19 and the outlet pipe 20 Wires 21 are arranged between them, and the bottom of the first fan 8 is provided with a first steam guide pipe 10 and a second steam guide pipe 11, and the second steam guide pipe 11 is arranged inside the first steam guide pipe 10. The bott...

Embodiment 2

[0029] Further, in the above-mentioned embodiment 1, an atomization chamber 22 is provided on the side of the first casing 1, an atomization cup 23 is provided inside the atomization chamber 22, and a heating device is provided on the inner wall of the atomization cup 23. The element and the bottom of the inner chamber are provided with an ultrasonic nebulizer, and the atomization chamber 22 is provided with a sealing cover 24, and the sealing cover 24 is movably connected with the first casing 1 through a hinge.

[0030] Further, in the above-mentioned embodiment 1, a handle 25 is provided on the top of the second casing 6, and an elastic layer 26 is sleeved on the outside of the handle 25, and the elastic layer 26 is made of rubber material. The outer side of the elastic layer 26 is provided with anti-skid lines for users to hold.

[0031] Further, in the above-mentioned embodiment 1, the top cover 27 is provided on the top of the first casing 1, and the top cover 27 is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com