A kind of fast and controllable preparation method of cocoon silk fibroin short fiber

A technology of short fibers and cocoon silk, which is applied in the field of preparation of cocoon silk fibroin short fibers, can solve the problems of difficult to control the degree of hydrolysis, severe reaction conditions, and great harm to human body, and achieves easy batch processing, simple process and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

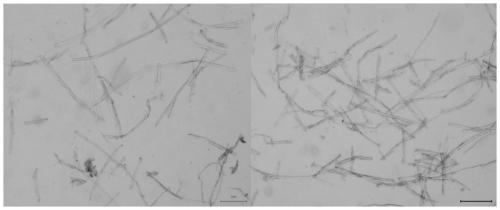

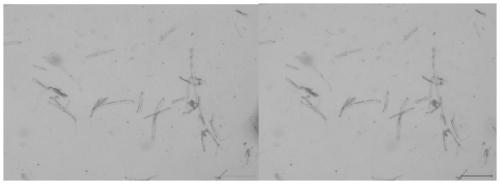

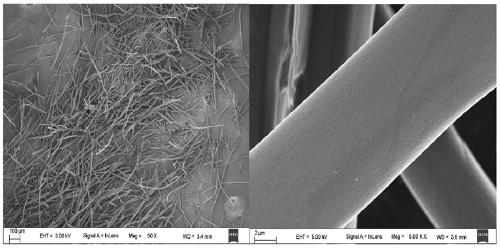

[0035] Dissolve 5g of silkworm cocoons in a mixed solution consisting of 7g of lithium hydroxide, 10g of sodium hydroxide, 70g of urea and 120g of water, and add alcohol solution drop by drop to the mixed solution of silkworm cocoons (ethanol is used for alcohol), Control the dropping rate at 1mL / min to obtain a mixed solution with an alcohol mass concentration of 2%. The obtained mixed solution was incubated at room temperature for 3 to 3.5 hours, and intermittently supplemented with slight stirring and dispersion at room temperature to obtain a length mainly Cocoon silk fibroin short fiber solution with a uniform distribution of 1mm to 3mm; place the prepared cocoon silk fibroin short fiber solution in a dialysis bag for dialysis treatment, and change the ultrapure water every 3 hours. Dialysis for 2 days. Afterwards, the insoluble particles in the cocoon silk fibroin short fiber solution are removed with a suction filter (washed 4 times with deionized water) and qualitative...

Embodiment 2

[0037] Dissolve 10g silkworm cocoons in a mixed solution consisting of 12g lithium hydroxide, 20g sodium hydroxide, 120g urea and 240g water, add alcohol solution dropwise to the mixed solution (propanol is used for alcohol), and control the dropping rate as 1mL / min to obtain a mixed solution with a mass concentration of alcohols of 7%. The obtained mixed solution was incubated at room temperature for 5.5-6.5 hours, and intermittently supplemented with slight stirring and dispersion at room temperature to obtain a length of 700μm-1.2 mm and uniformly distributed cocoon fibroin short fiber solution; the prepared cocoon silk fibroin short fiber solution is placed in a dialysis bag for dialysis treatment, and the ultrapure water is changed every 3 hours, and the ultrapure water is dialyzed for 3 sky. Afterwards, the insoluble particles in the cocoon silk fibroin short fiber solution are removed with a suction filter (washed 5 times with deionized water) and qualitative filter pap...

Embodiment 3

[0039] Dissolve 20g silkworm cocoons in a mixed solution consisting of 32g lithium hydroxide, 40g sodium hydroxide, 320g urea and 480g water, add alcohol solution (isopropanol) drop by drop to the mixed solution, and control the dropping speed 1mL / min to obtain a mixed solution with an alcohol mass concentration of 8%. The obtained mixed solution was incubated at room temperature for 7.5 to 8 hours, supplemented by light stirring and dispersion treatment at room temperature intermittently to obtain a length of mainly 400 μm to 1mm and Uniformly distributed cocoon fibroin short fiber solution; put the prepared cocoon silk fibroin short fiber solution in a dialysis bag for dialysis treatment, change the ultrapure water every 3 hours, and dialyze in the ultrapure water for 3 days. Afterwards, the insoluble particles in the cocoon silk fibroin short fiber solution are removed with a suction filter (washed 5 times with deionized water) and qualitative filter paper. After all the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com