A three-dimensional shell-imitated material and a preparing method thereof

A structural material and shell imitation technology, applied in the field of materials, can solve the problems of slow preparation method and poor material tolerance, and achieve the effect of simple operation and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

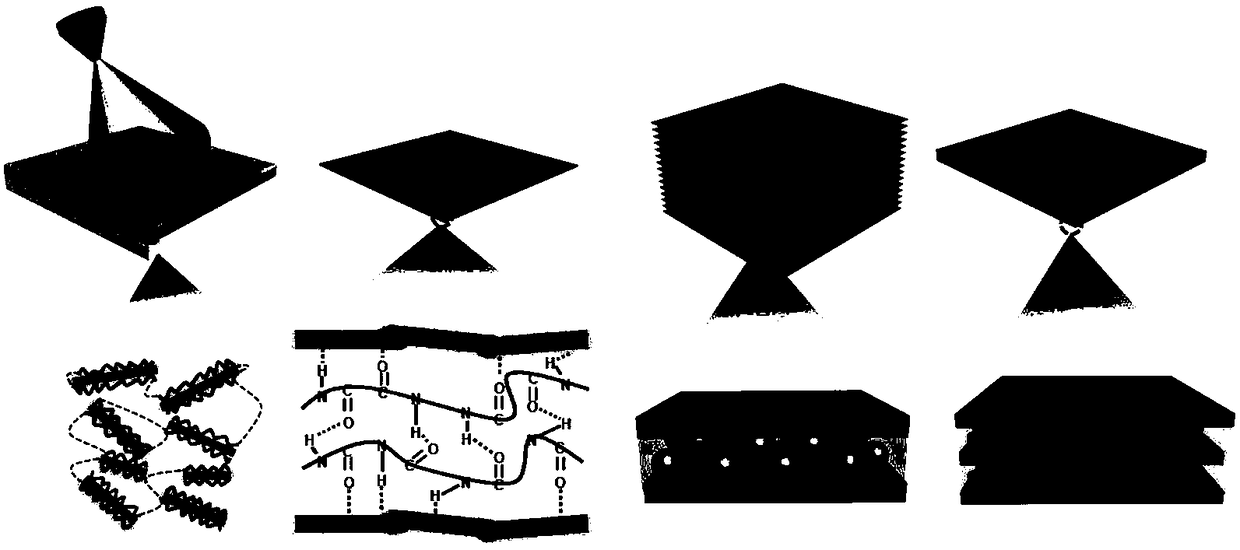

[0033] The invention provides a preparation method of a three-dimensional imitation shell structure material, comprising:

[0034] A) the aramid fiber is in a solvent, and the aramid nanofiber solution is obtained by stirring and stripping;

[0035] The mica dispersion is mixed with a surface modifier and a dispersant to obtain a suspension of mica flakes modified by the surface modifier;

[0036] B) mixing the mica sheet suspension modified by the surface modifier with the aramid fiber dissolving solution to obtain a mica-aramid nanofiber dispersion;

[0037] C) the mica-aramid nanofiber dispersion is sprayed into a composite film by spraying assembly method;

[0038] D) spraying zinc oxide nanoparticles on the composite film, impregnating epoxy resin, stacking, and hot pressing to obtain a three-dimensional imitation shell structure material.

[0039] The preparation method of the three-dimensional imitation shell structure material provided by the invention first dissolve...

Embodiment 1

[0074] Preparation of artificial shell composites:

[0075] a. Prepare 10mg / mL polyacrylic acid, 0.1mol / L sodium chloride solution, 1L, add 20mL polyacrylic acid and sodium chloride solution to the 4mg / mL mica flake suspension, stir at room temperature for 1h, centrifuge at 8000r / min for 10min, After washing for 3 times, a suspension of 2% polyacrylic acid-modified nano-mica flakes was obtained. figure 2 It is a scanning electron micrograph of a polyacrylic acid-modified mica sheet in Example 1 of the present invention.

[0076] b. Weigh 10g of potassium hydroxide and 10g of aramid fibers into a 2L beaker containing 1L of dimethyl sulfoxide, stir for one week at room temperature, and wait until the fibers are completely peeled off to obtain a 1% solution of aramid nanofibers. The scanning electron micrographs of aramid nanofibers prepared under these conditions are as follows: image 3 as shown, image 3 It is a scanning electron micrograph of the aramid nanofiber in Examp...

Embodiment 2

[0082] Preparation of pure aramid nanofiber three-dimensional bulk composites:

[0083] a. The preparation of aramid nanofiber is the same as in Example 1.

[0084] b. The preparation of pure aramid nanofiber membrane is the same as in Example 1.

[0085] c, Pure aramid nanofiber membrane as the object to prepare three-dimensional composite materials. Prepare a certain concentration of nano-zinc oxide solution, use a small spray gun to evenly spray a layer of nanoparticles on the surface of the film, after drying, use scissors to cut the film into ~2.25cm*4cm, and measure the film thickness with a spiral micrometer. Configure a certain volume of epoxy resin, use the infiltration method to coat the epoxy resin, and after the composite film is infiltrated, use the lamination method to tightly bond the films together. After the block is briefly covered with filter paper, use a tablet press. Under the action of 60°C and 30KPa for 48 hours, a pre-pressed block with a certain hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com