Foam concrete, preparation method of foam concrete, and building wallboard built by using foam concrete

A foamed concrete and construction technology, which is applied in the field of building wall panels, foamed concrete and its preparation, can solve the problems of poor thermal insulation performance improvement effect, etc., and achieve the effect of increasing the lifting effect, increasing the mechanical performance, and increasing the thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

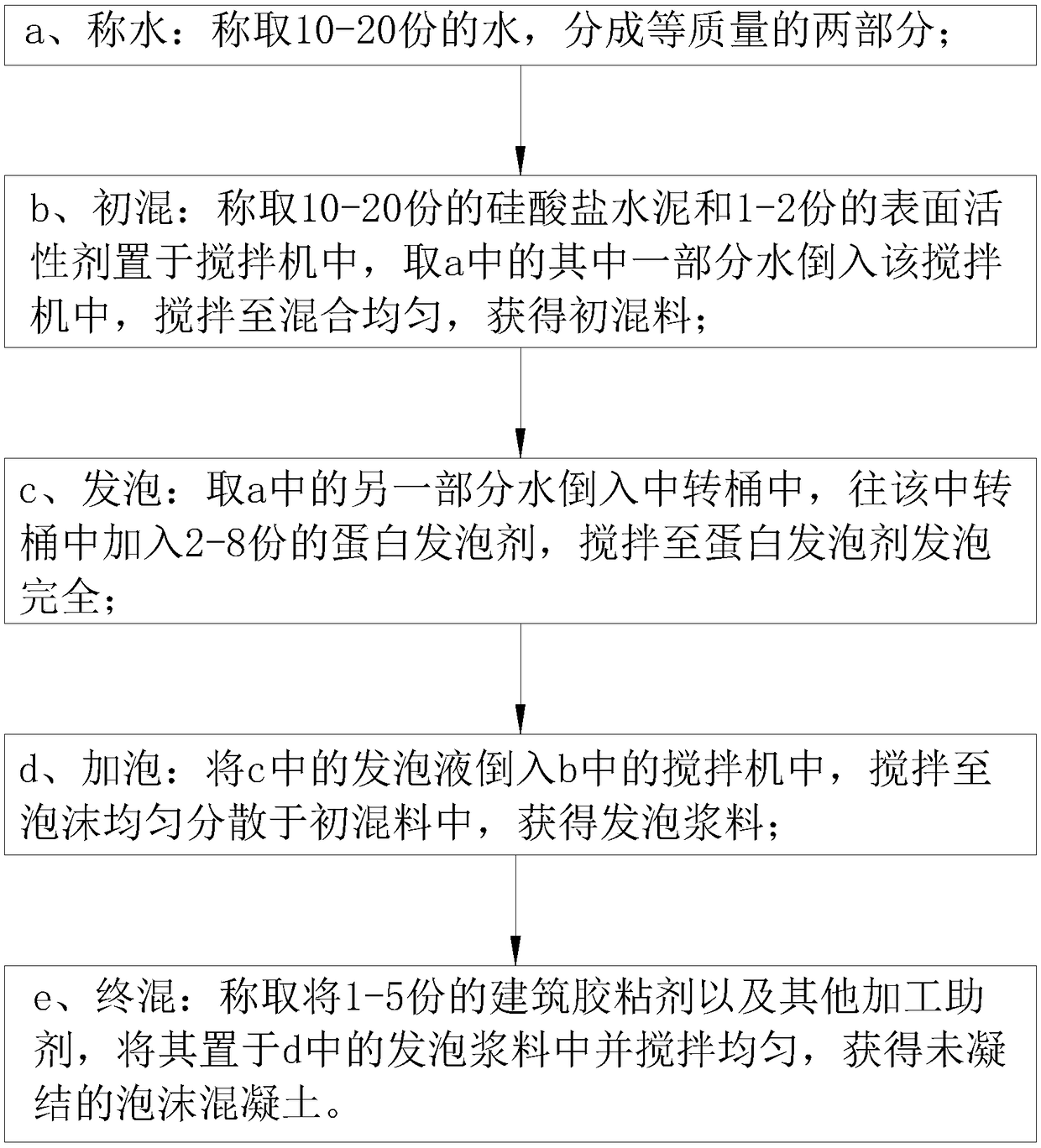

[0046] The preparation method of foam concrete among the present invention, see figure 1 , including the following steps:

[0047] a. Weighing water: Weigh 10-20 parts of water and divide it into two parts of equal mass;

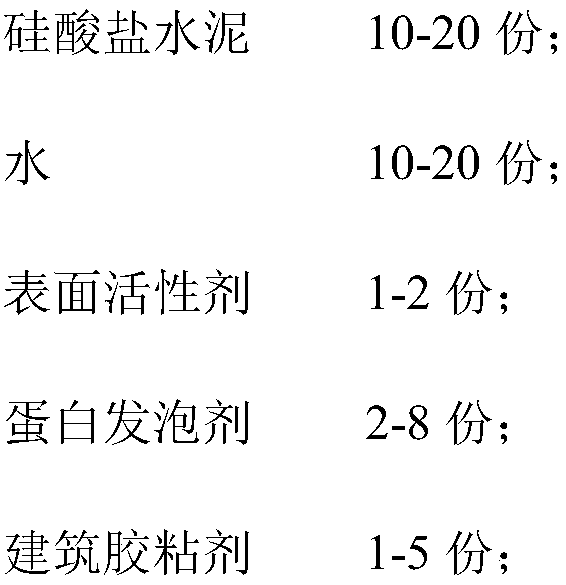

[0048] b. Initial mixing: Weigh 10-20 parts of Portland cement and 1-2 parts of surfactant and place them in a mixer, take part of the water in a and pour them into the mixer, and mix them at 25±5°C, 300 Stir under the condition of -350r / min until evenly mixed to obtain the initial mixture;

[0049] c. Foaming: Take another part of the water in a and pour it into the transfer bucket, add 2-8 parts of protein foaming agent into the transfer bucket, and stir it under the conditions of 25±5°C and 300-350r / min until The protein foaming agent foams completely;

[0050] d. Adding foam: Pour the foaming solution in c into the mixer in b, and stir under the conditions of 25±5°C and 300-350r / min until the foam is evenly dispersed in the initial mixture to obtain a...

Embodiment 1- Embodiment 11

[0054] Embodiment 1-Example 11 all prepare corresponding foamed concrete on the basis of the preparation method of above-mentioned foamed concrete, and its difference is that the components used in each embodiment and the weight of each component are different, specific each The components of the embodiment and the weight of each component are shown in the table below, and the weight unit is kg.

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com