Automatic cake production system with discharge packaging function

A production system and cake technology, applied in packaging, packaged food, transportation and packaging, etc., can solve the problems of high labor intensity, inability to guarantee a hygienic environment, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing

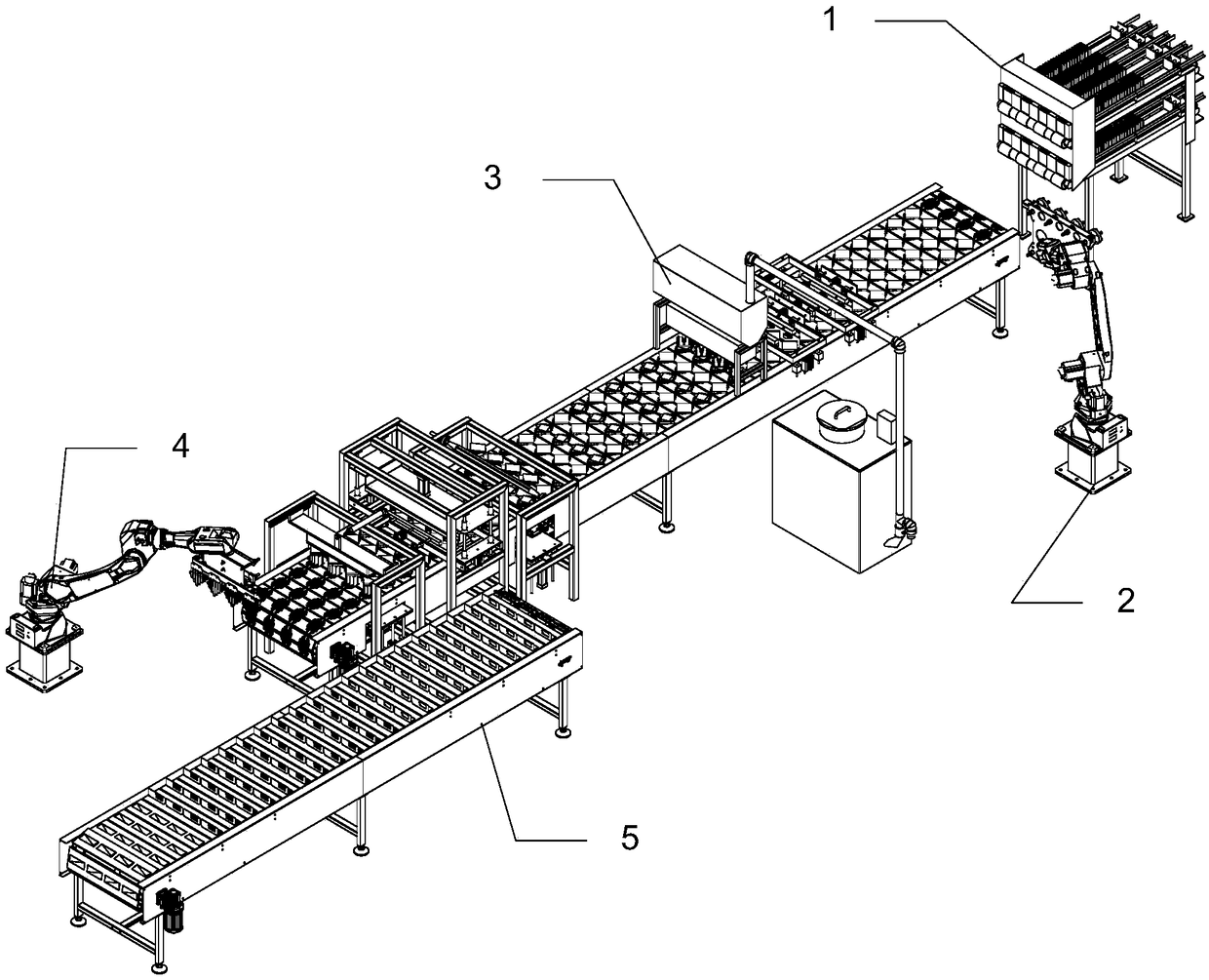

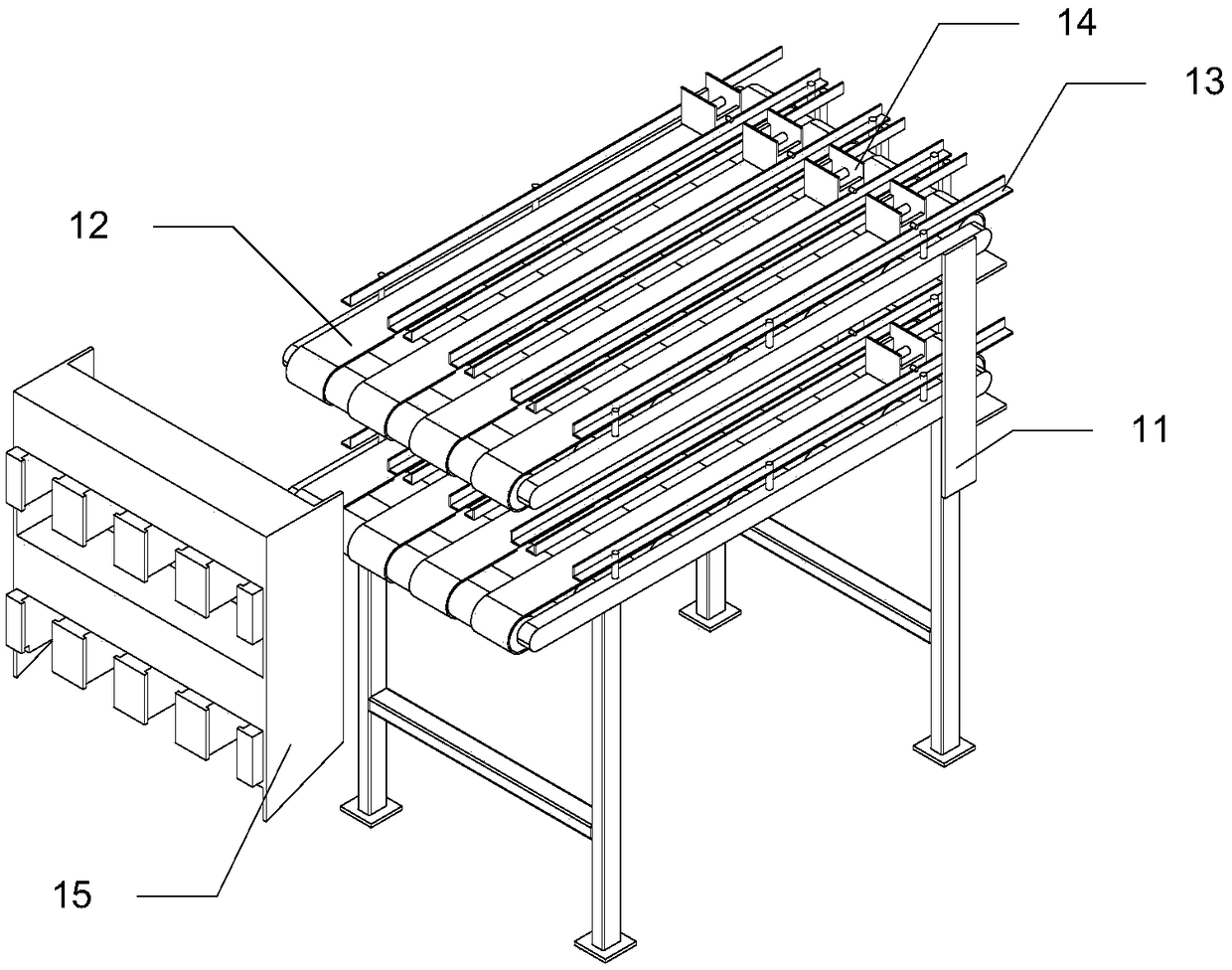

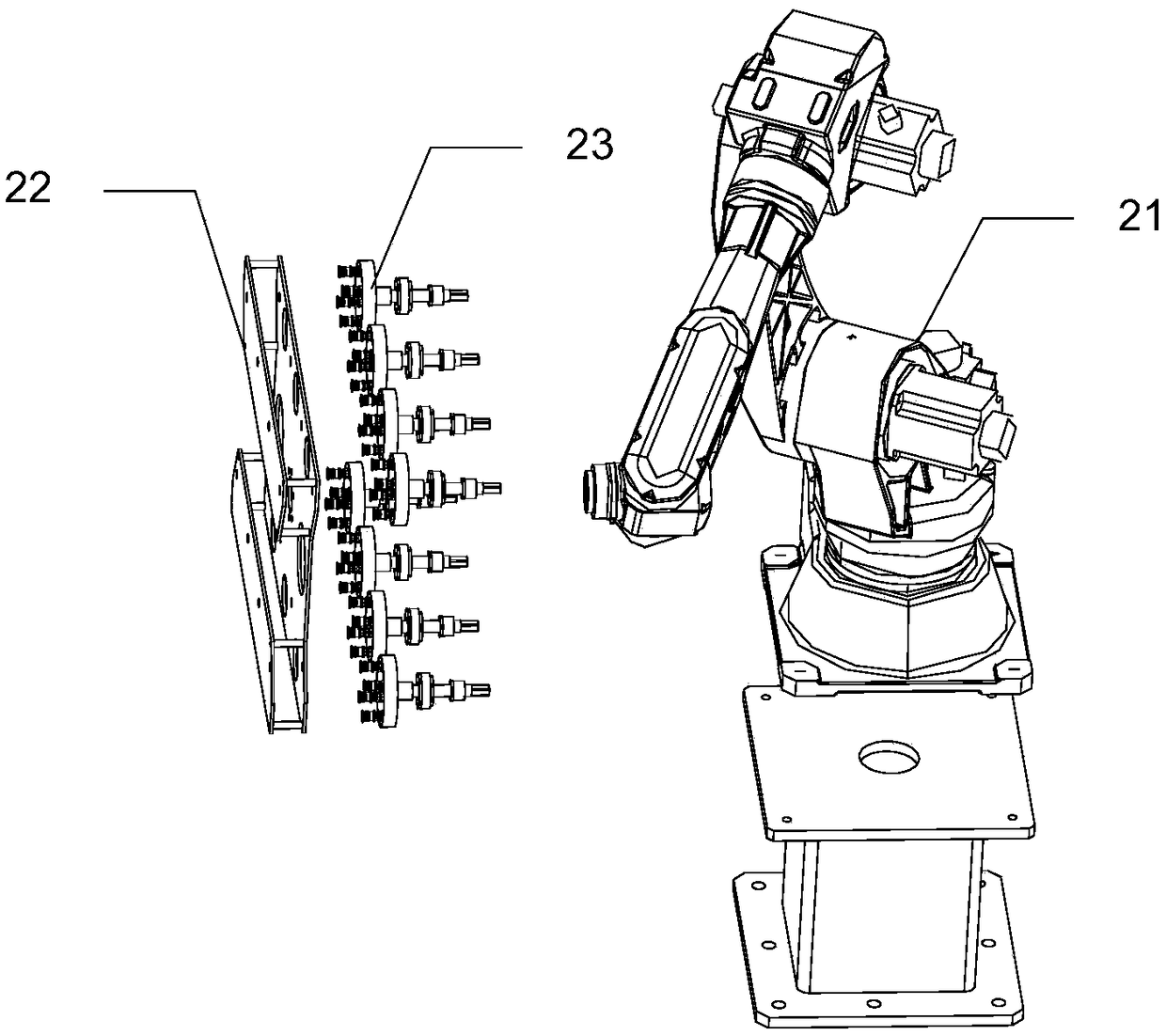

[0040] like figure 1 As shown, this is an automatic production system for cakes and hamburgers, including a feeding mechanism 1, a first manipulator mechanism 2, a processing mechanism 3, a second manipulator mechanism 4 and a packaging transmission mechanism 5. The feeding mechanism 1 is placed at the front end of this system. The processing mechanism 3 is connected with the feeding mechanism 1 , and the toast slice is removed from the feeding mechanism 1 by the first manipulator mechanism 2 and placed on the processing mechanism 3 . The front end of the packaging mechanism and the rear end of the processing mechanism 3 are placed side by side, and the cake is clamped from the processing mechanism 3 by the second manipulator mechanism 4 and placed on the packaging transmission mechanism 5 . The toast slices are artificially placed on the feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com