Self-adjustment uniform-pressure sealing mechanism of compound air adjustment packing machine

A self-adjusting, packaging machine technology, applied in packaging automatic control, packaging sealing/tightening, packaging, etc., can solve the problems of difficult storage, sealing air leakage, sealing displacement, etc., to achieve difficult to move, strong friction, bite strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

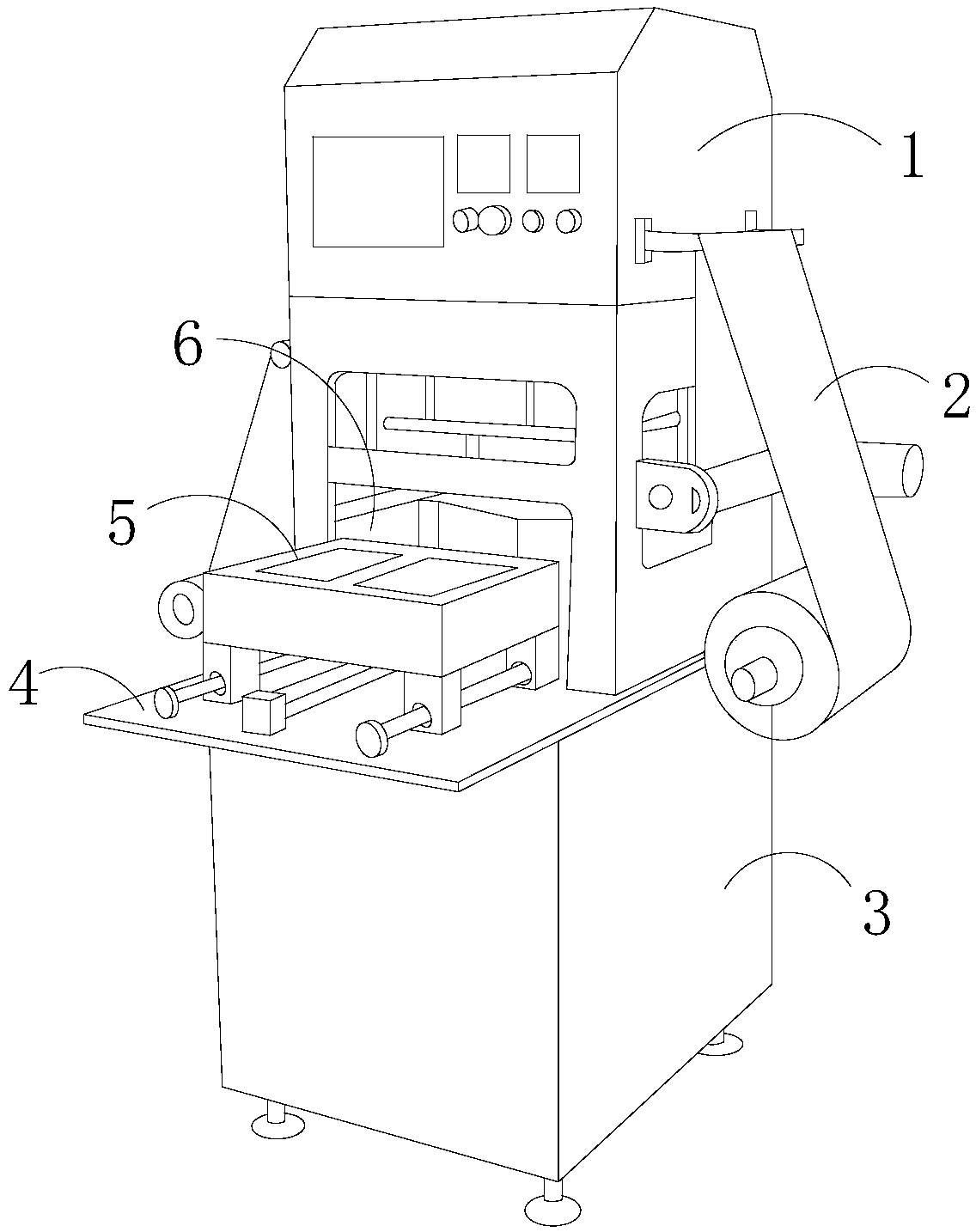

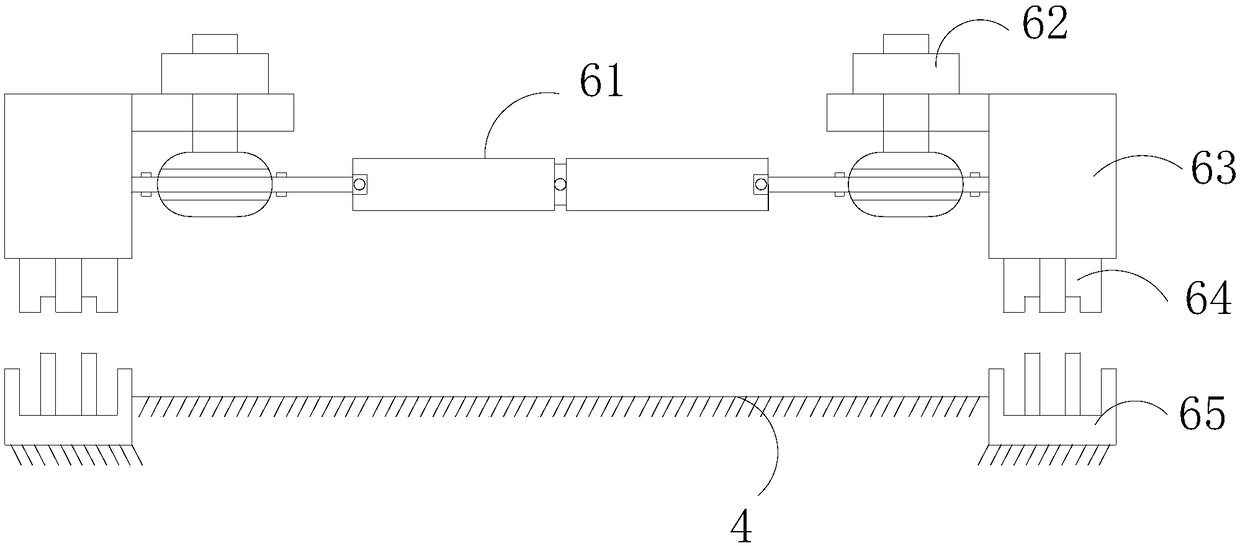

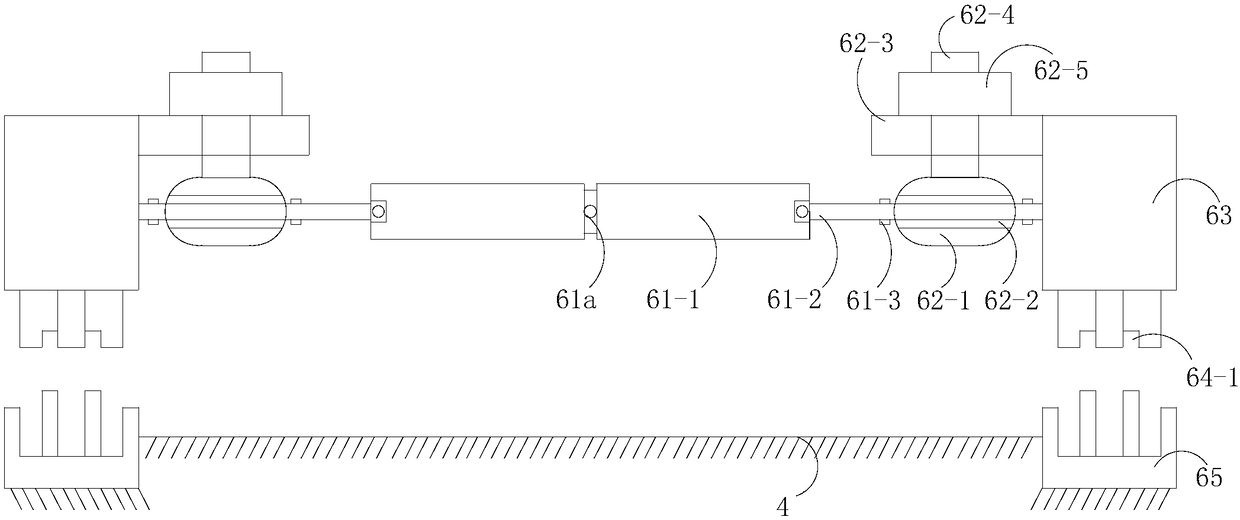

[0023] see Figure 1-Figure 3 , the present invention provides a self-adjusting pressure-equalizing sealing mechanism for a composite modified atmosphere packaging machine, the structure of which includes a control box 1, a feeding roller 2, a machine bottom box 3, an operating platform 4, a placing box 5, and a self-adjusting structure 6. The bottom of the machine The top surface of the box 3 is the operation platform 4, the control box 1 is vertically installed on the operation platform 4, and the feeding rollers 2 are installed on both sides of the control box 1 and cooperate with the self-adjusting structure 6 located inside the bottom end of the control box 1, so The placing box 5 and the operating platform 4 adopt sliding fit, the placing box 5 and the self-adjusting structure 6 are located on the same horizontal plane and the two cooperate with each other, and the self-adjusting structure 6 is provided with two and is stacked with respect to the vertical centerline of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com