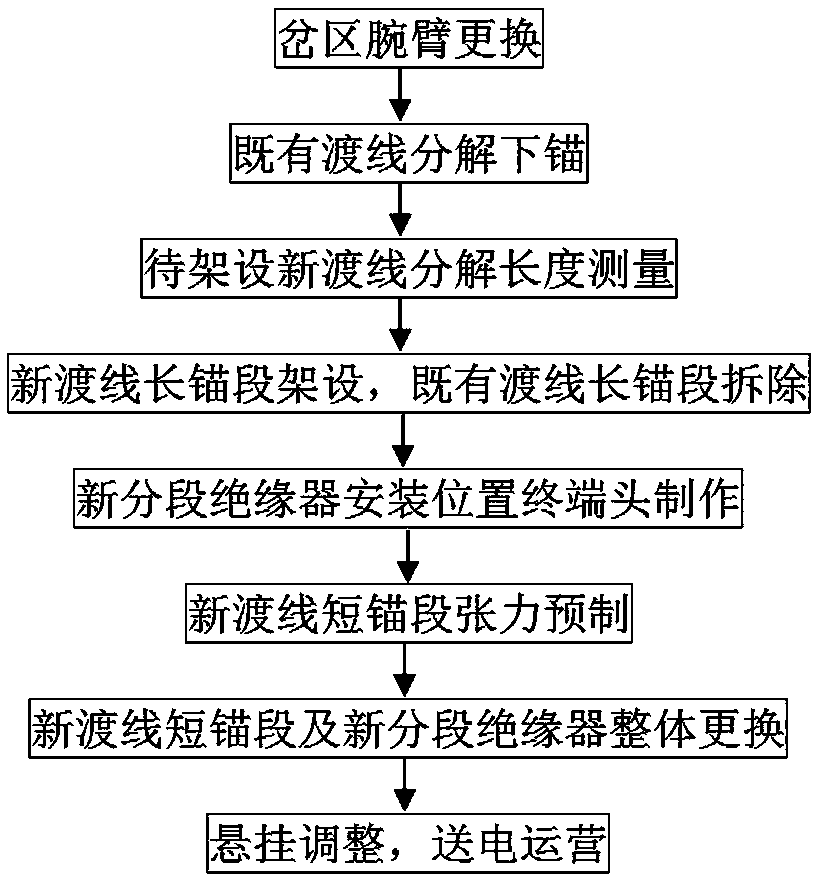

Construction method of integral replacement of existing electric railway overhead contact system crossover and section insulator

A segmented insulator and electrified railway technology, applied in the direction of overhead lines, etc., can solve the problems of large number of vertical skylights, many safety hazards, and difficulty in implementation, and achieve the effect of getting rid of complete dependence, fewer operation items, and smaller task load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

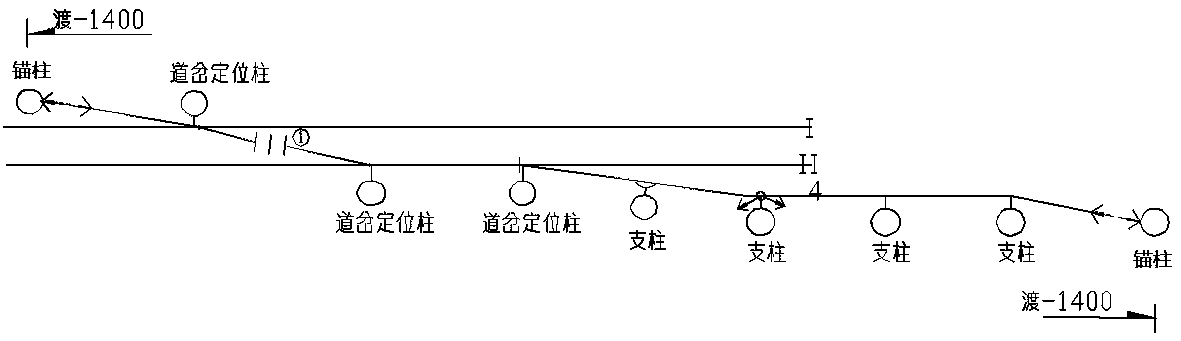

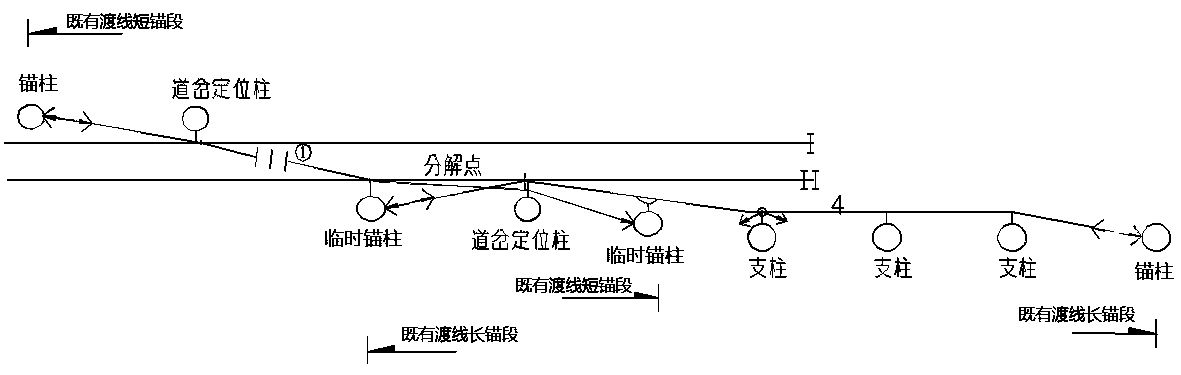

[0032] The following is an example of the Fengsha Line expansion project to describe the present invention in detail. Fengsha Line approves vertical skylights for 60 minutes every month, and the effective construction time after power failure is about 40 minutes. Only 2 vertical skylights are approved for each station every month Skylights, affected by transportation, construction skylights are often canceled. Considering the Xuanhua Station of the Fengsha Line, there are 6 crossover lines involving segmental insulators between the uplink and downlink in this station, and 2 crossover lines only involve the anchor section across the uplink and downlink. According to the traditional construction method, 22 vertical skylights are needed regardless of the skylight time. According to the Fengsha Line, only 2 vertical skylights are approved for each station every month, and only 11 months of construction are required for the replacement of the crossing line at Xuanhua Station. Howeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com