High performance PTFE coated needle felt and preparation method thereof

A high-performance, needle-punched felt technology, applied in the field of needle-punched felt, can solve the problems of low structural strength of PTFE needle-punched felt, and achieve the effects of high fixing strength, convenient and fast operation, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

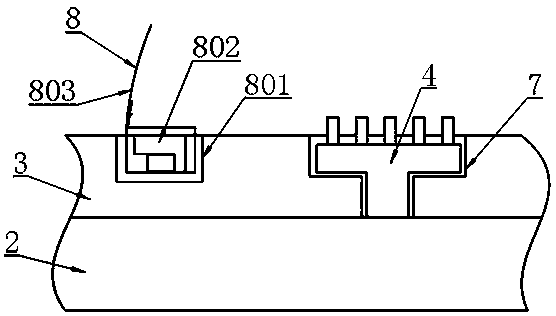

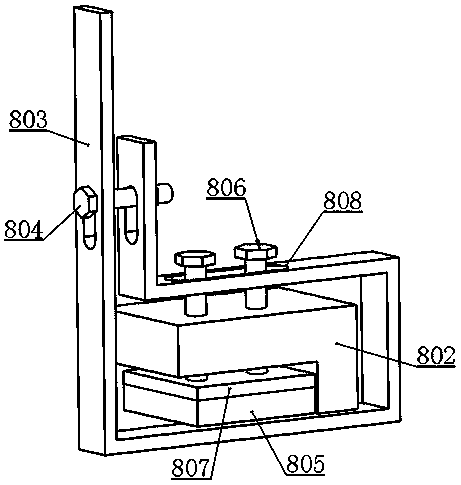

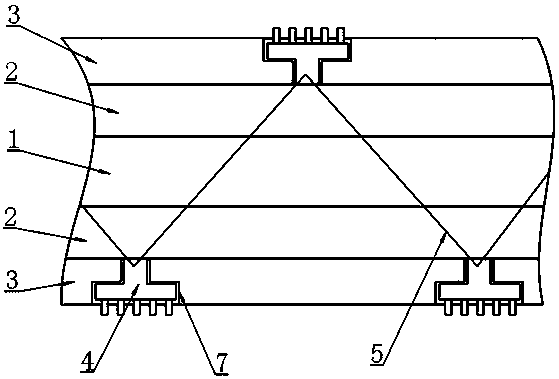

[0028] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Image 6 As shown, the high-performance PTFE coated needled felt and its preparation method include a PTFE mesh base layer 1, an insulating cotton layer 2 arranged on both sides of the PTFE mesh base layer 1, and an insulating cotton layer 2 arranged on The PTFE coating layer 3 is provided with a heat dissipation copper plate 4 on the PTFE coating layer 3, and a connecting iron strip 5 is inserted on the heat dissipation copper plate 4, and the connecting iron strip 5 passes through the PTFE mesh base layer 1 and Insulation cotton layer 2, said heat dissipating copper plate 4 is provided with a magnetic fixing unit 6 for fixing and installing said connecting iron bar 5 by means of magnetic attraction, and said PTFE coating layer 3 is also provided with a heat sink unit 8 , The heat sink unit 8 includes a U-shaped mounting groove 801 disposed on the PTFE coating layer 3, and a coating layer protruding post 802 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com