Cement mixer based on uniform agitation of lead screw

A cement mixer and uniform mixing technology, applied in cement mixing devices, control devices, clay preparation devices, etc., can solve the problems of uneven and insufficient mixing of the items to be mixed, inability to control the mixing temperature of the mixing box, and insufficient mixing at the center position. , to achieve the effect of simple structure, improving stirring effect and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

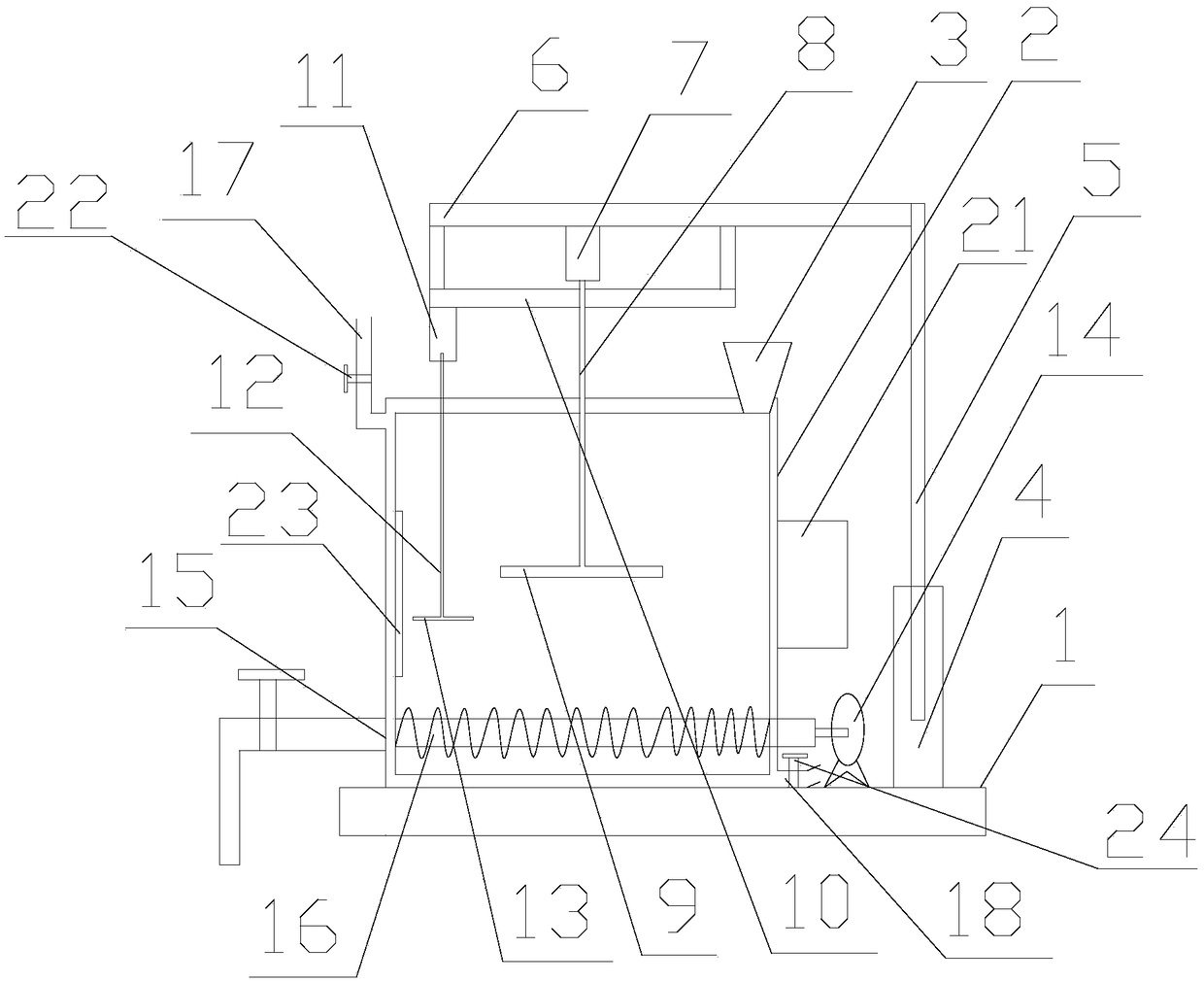

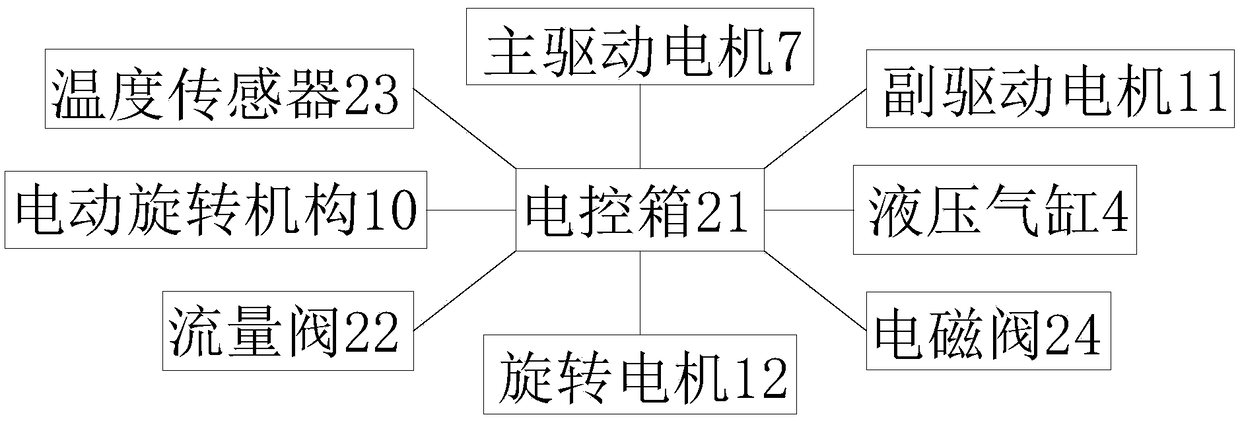

[0021] Such as figure 1 and 2 As shown, the cement mixer based on screw uniform mixing provided by the present invention has simple structure, reasonable design, convenient use, can control the mixing temperature in the mixing tank, and expands the scope of application. The present invention includes a base 1 fixed on the base 1, a mixing box 2 with a feeding funnel 3 connected to the top, and a double-layer structure, located on one side of the mixing box 2 and fixed on the base 1, with a vertical piston rod 5 The hydraulic cylinder 4 is vertically connected with the vertical piston rod 5 and is positioned at the support rod 6 directly above the mixing box 2, and the main drive motor 7 fixedly connected with the support rod 6 is located in the mixing box 2 and is connected to the drive motor through the main stirring shaft 8. 7. The main stirring blade 9 connected to the drive shaft, located directly below the support rod 6, the electric rotating mechanism 10 fixed by the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com