Wood door perforation cooling device

A technology of cooling device and wooden door, which is applied in the direction of wood processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of poor workshop environment, poor workshop environment, overheating and fracture of drill bits, etc., and achieve good cooling effect and reduce Maintenance frequency, the effect of low maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

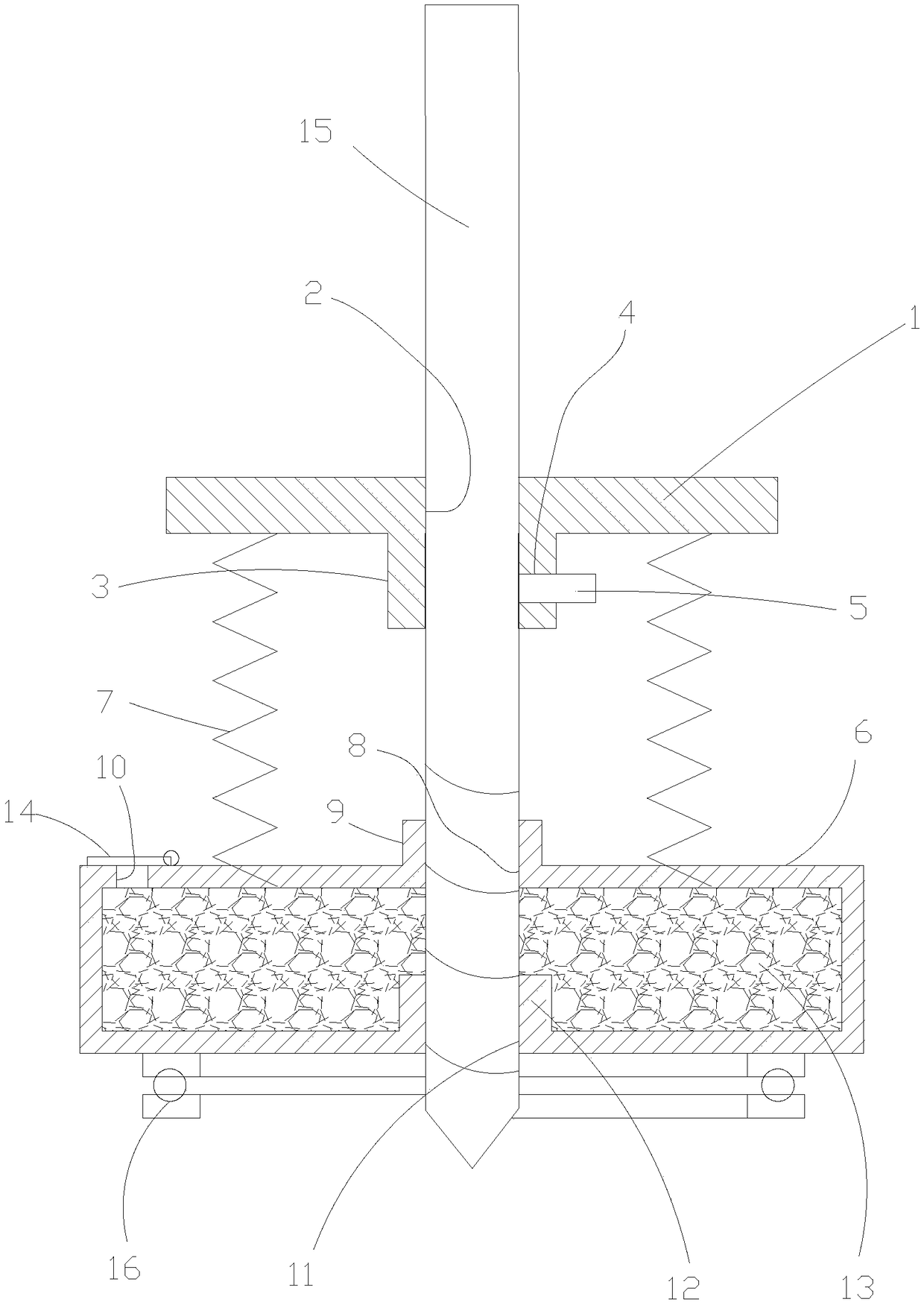

[0013] Example. A wooden door perforating cooling device, comprising a circular fixing plate 1, the fixing plate 1 is provided with a first through hole 2 in the axial direction, the edge of the first through hole 2 is provided with a downward first flange 3, the second The side wall of a flanging 3 is provided with a threaded hole 4, and a screw 5 is arranged in the threaded hole 4, and a cooling box 6 is provided under the fixed plate 1, and the fixed plate 1 is connected with the cooling box 6 by a spring 7, and the cooling box 6 The top plate is provided with a second through hole 8 coaxial with the first through hole 2, and the edge of the second through hole 8 is provided with an upward second flange 9, and one side of the second flange 9 is provided with a water inlet hole 10. The bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com