Fiber core and silica gel ring assembly center and pre-assembly transfer method

A fiber core and silicone ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not conforming to modern production rhythm, high scrap rate, low assembly efficiency, etc., to simplify the structure, ensure continuity, The effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

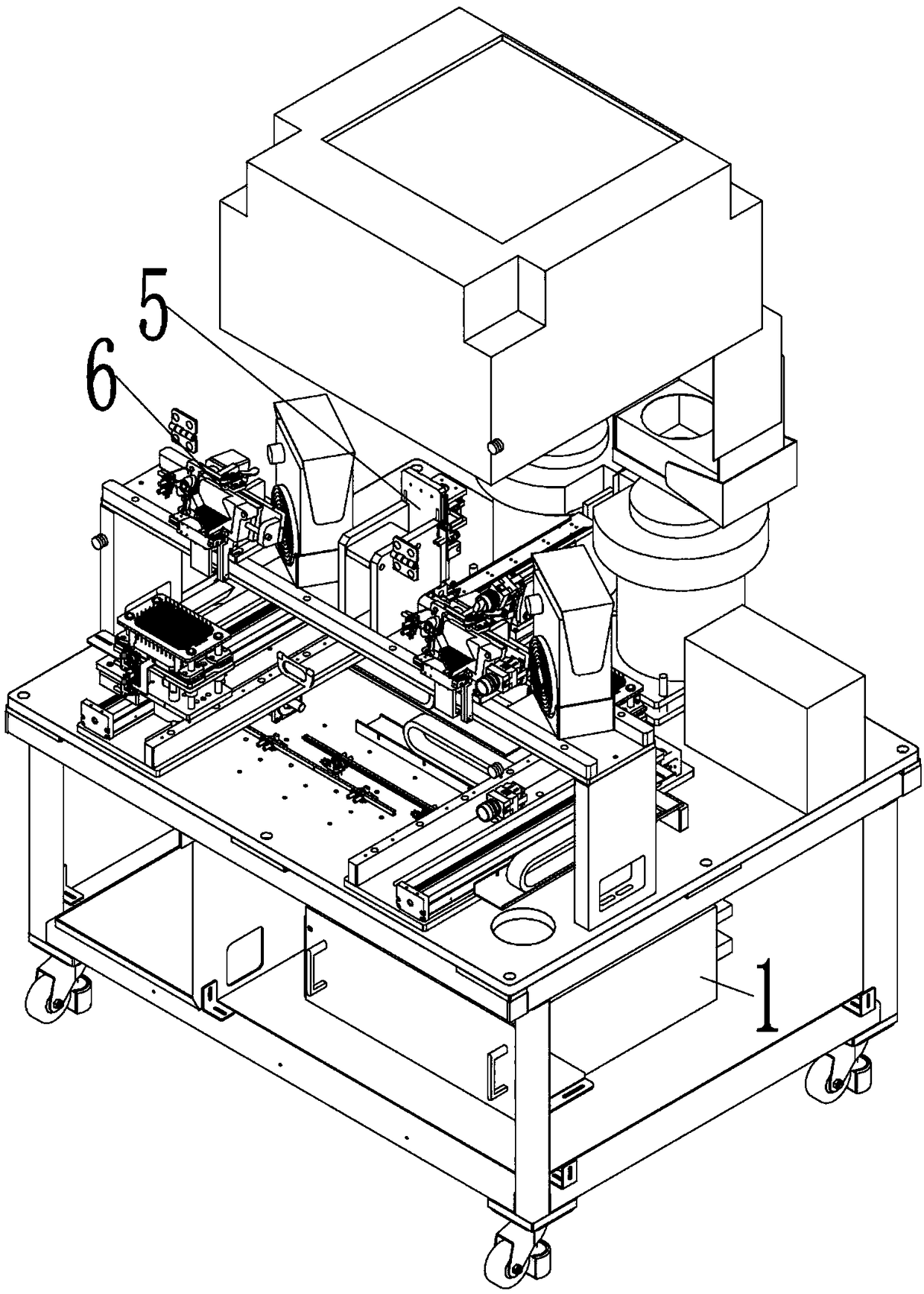

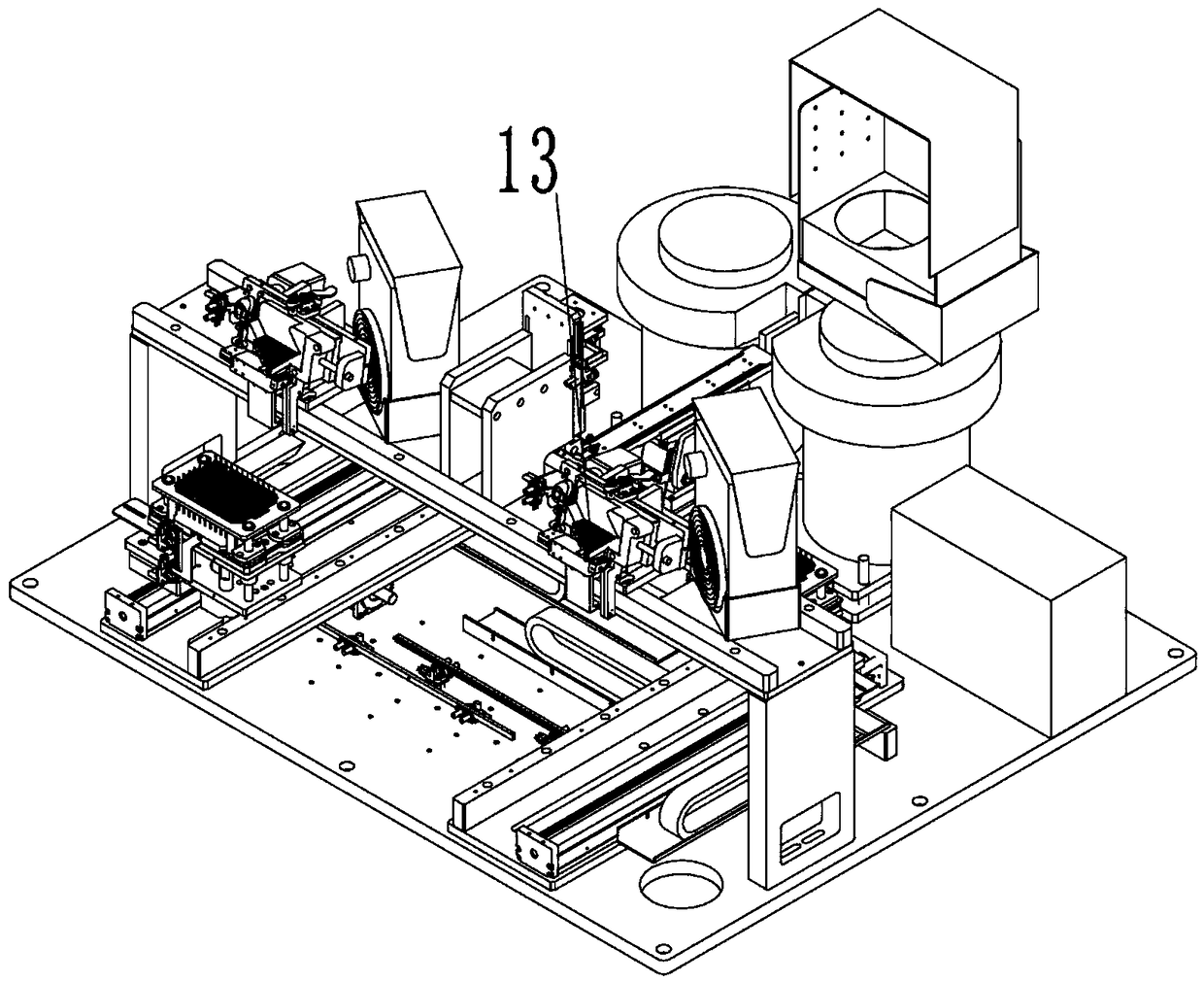

[0025] like Figure 1-7 As shown, the fiber core and silicone ring assembly center of this embodiment includes a main frame 1, a delivery rubber ring device 5 vertically arranged on the main frame 1, and a delivery needle device 6 arranged on the main frame 1;

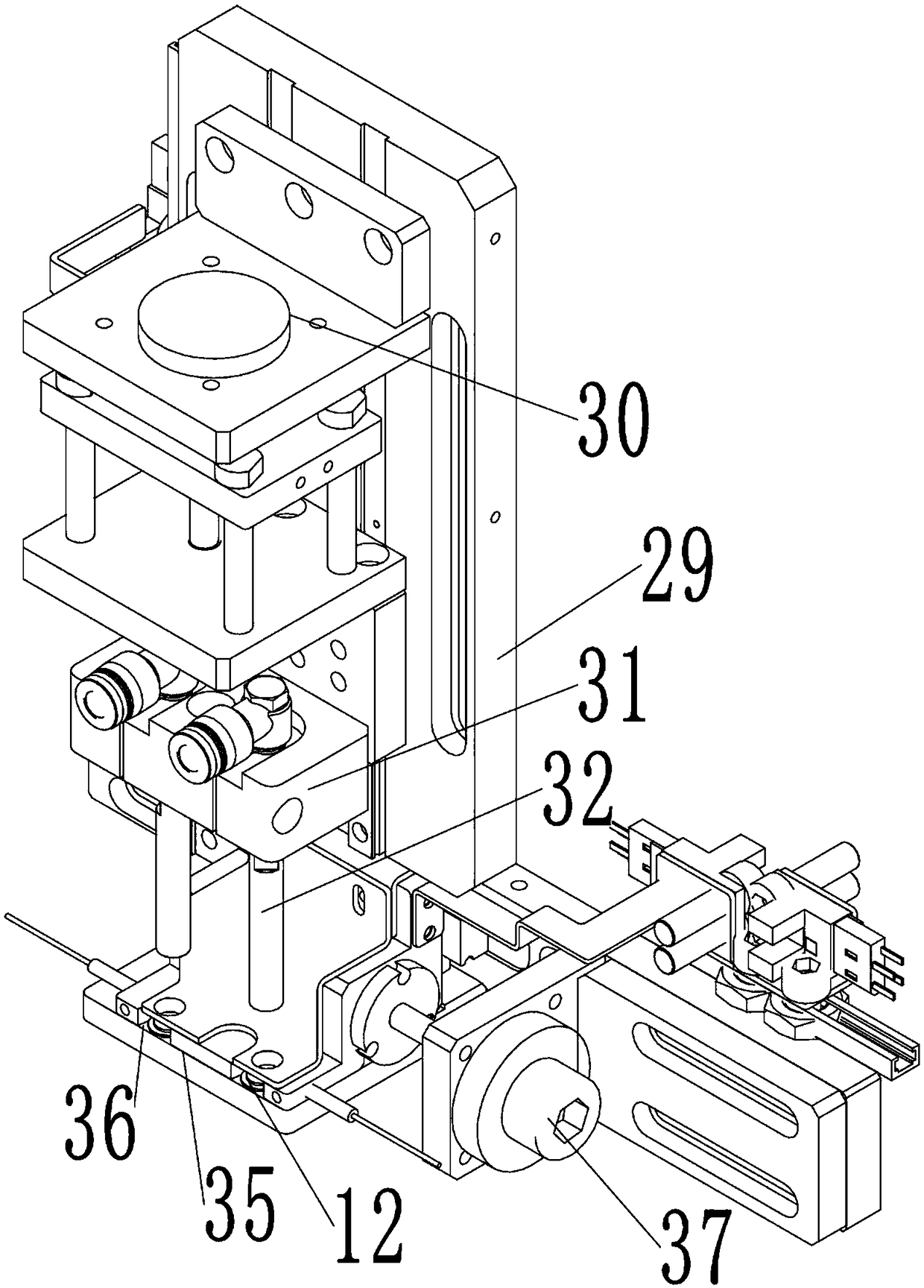

[0026] Conveying the apron device 5 comprises the apron holder 29 vertically arranged on the main frame 1, the apron lift cylinder 30 vertically arranged on the apron holder 29, the apron lift cylinder 30 lower end arranged on the apron holder The apron lifting seat 31 that slides up and down on the 29, the apron horizontal push rod 37 that is horizontally arranged on the apron frame 29, the apron middle rotating seat on the apron horizontal push rod 37 and that moves laterally on the apron lifting seat 31 35. The apron transfer channel 36 arranged on the apron transfer seat 35 and used to accommodate the silicone ring parts 12, and the apron lifting seat 31 vertically arranged on the lower end is used to absorb the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com