Heat exchange tube reaming device

A technology of heat exchange tubes and hole heads, which is applied in the field of heat exchange tube reaming devices, can solve the problems of heat exchange tubes relying on manpower, etc., and achieve the effects of reduced production costs, low failure rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

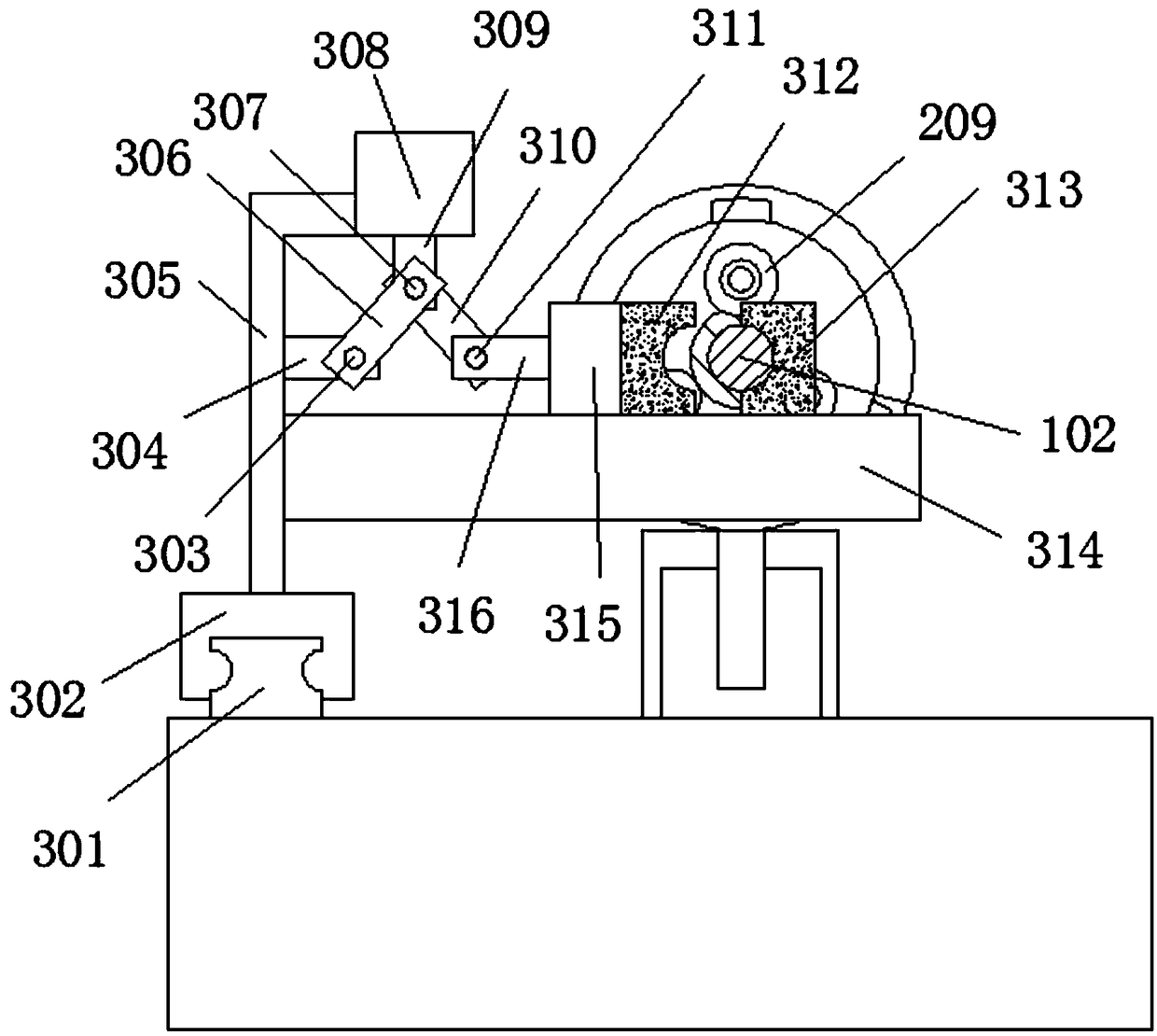

[0032] This embodiment provides a heat exchange tube expansion device, such as Figure 1 to Figure 7 shown.

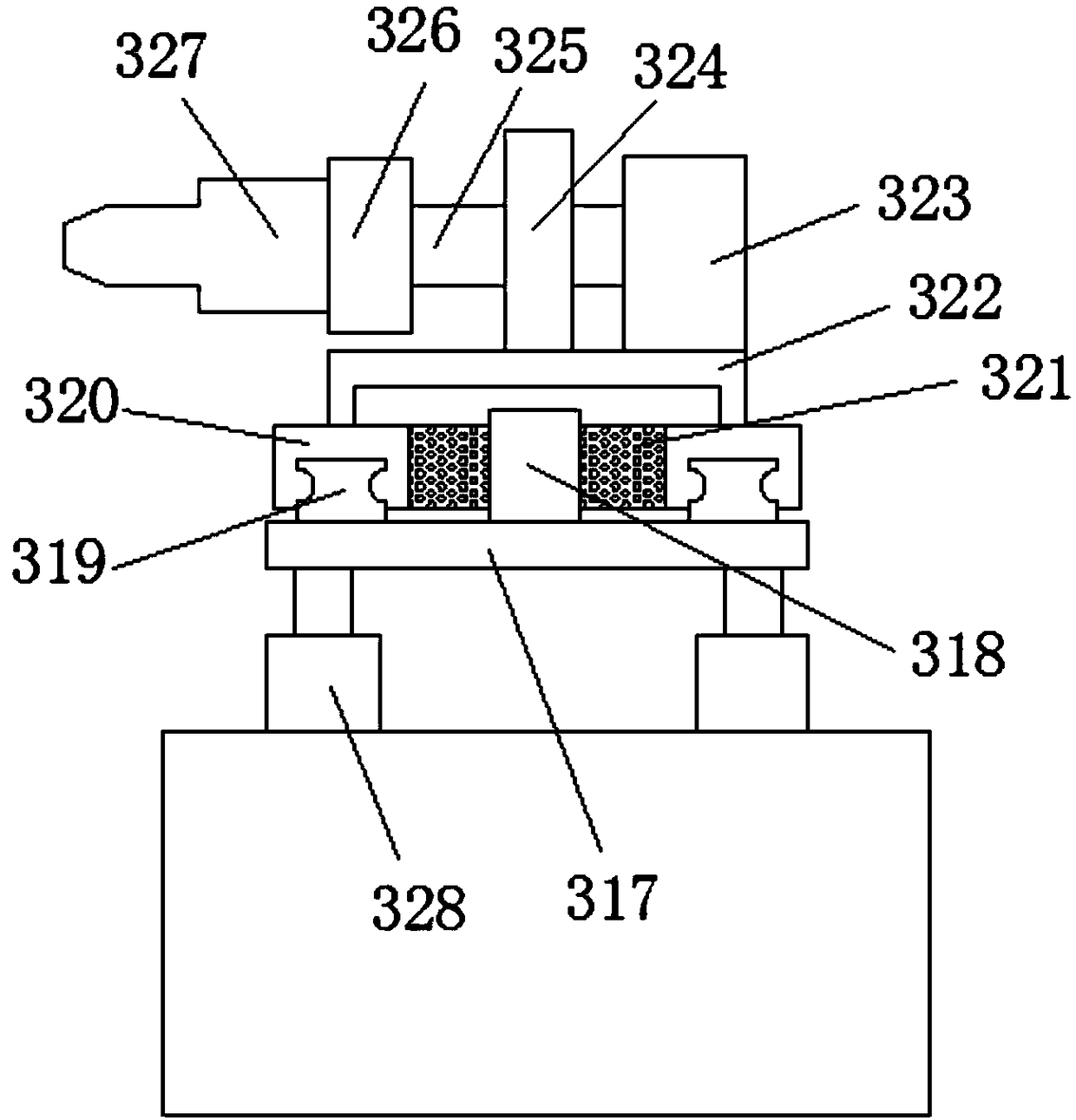

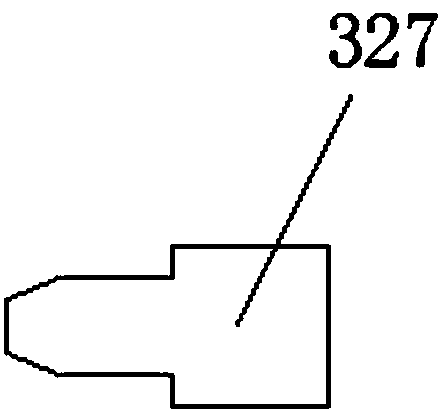

[0033] A heat exchange tube reaming device, including a reaming mechanism, a fixing mechanism for fixing the heat exchange tube 102 during reaming, and a transfer mechanism for transferring the heat exchange tube 102 to the next process after reaming, the reaming mechanism Including hydraulic cylinder six 323, the output end of hydraulic cylinder six 323 is connected with the reaming shaft 325, the end of the reaming shaft 325 is provided with a reaming head fixing seat 326, and the end of the reaming head fixing seat 326 is fixedly provided with a reaming Head one 327 and reaming head two 339, reaming head one 327 and reaming head two 339 are arranged in parallel.

Embodiment 2

[0035] This embodiment provides a heat exchange tube expansion device, such as Figure 1 to Figure 7 shown.

[0036]A heat exchange tube reaming device, including a reaming mechanism, a fixing mechanism for fixing the heat exchange tube 102 during reaming, and a transfer mechanism for transferring the heat exchange tube 102 to the next process after reaming, the reaming mechanism Including hydraulic cylinder six 323, the output end of hydraulic cylinder six 323 is connected with the reaming shaft 325, the end of the reaming shaft 325 is provided with a reaming head fixing seat 326, and the end of the reaming head fixing seat 326 is fixedly provided with a reaming Head one 327 and reaming head two 339, reaming head one 327 and reaming head two 339 are arranged in parallel.

[0037] The hydraulic cylinder six 323 is arranged on the support platform two 322, the support platform two 322 is arranged on the slide block three 320, the slide block three 320 is arranged on the guide ...

Embodiment 3

[0039] This embodiment provides a heat exchange tube expansion device, such as Figure 1 to Figure 7 shown.

[0040] A heat exchange tube reaming device, including a reaming mechanism, a fixing mechanism for fixing the heat exchange tube 102 during reaming, and a transfer mechanism for transferring the heat exchange tube 102 to the next process after reaming, the reaming mechanism Including hydraulic cylinder six 323, the output end of hydraulic cylinder six 323 is connected with the reaming shaft 325, the end of the reaming shaft 325 is provided with a reaming head fixing seat 326, and the end of the reaming head fixing seat 326 is fixedly provided with a reaming Head one 327 and reaming head two 339, reaming head one 327 and reaming head two 339 are arranged in parallel.

[0041] The hydraulic cylinder six 323 is arranged on the support platform two 322, the support platform two 322 is arranged on the slide block three 320, the slide block three 320 is arranged on the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com