Sliding block guide and precision adjustment structure applied to hot blanking press machine

A technology for adjusting structures and presses, applied to presses, metal processing equipment, forming tools, etc., can solve problems affecting the machining accuracy of workpieces, loss of guide gap, rupture of lubricating oil film, etc., to ensure operating accuracy, prolong service life, The effect of meeting market requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

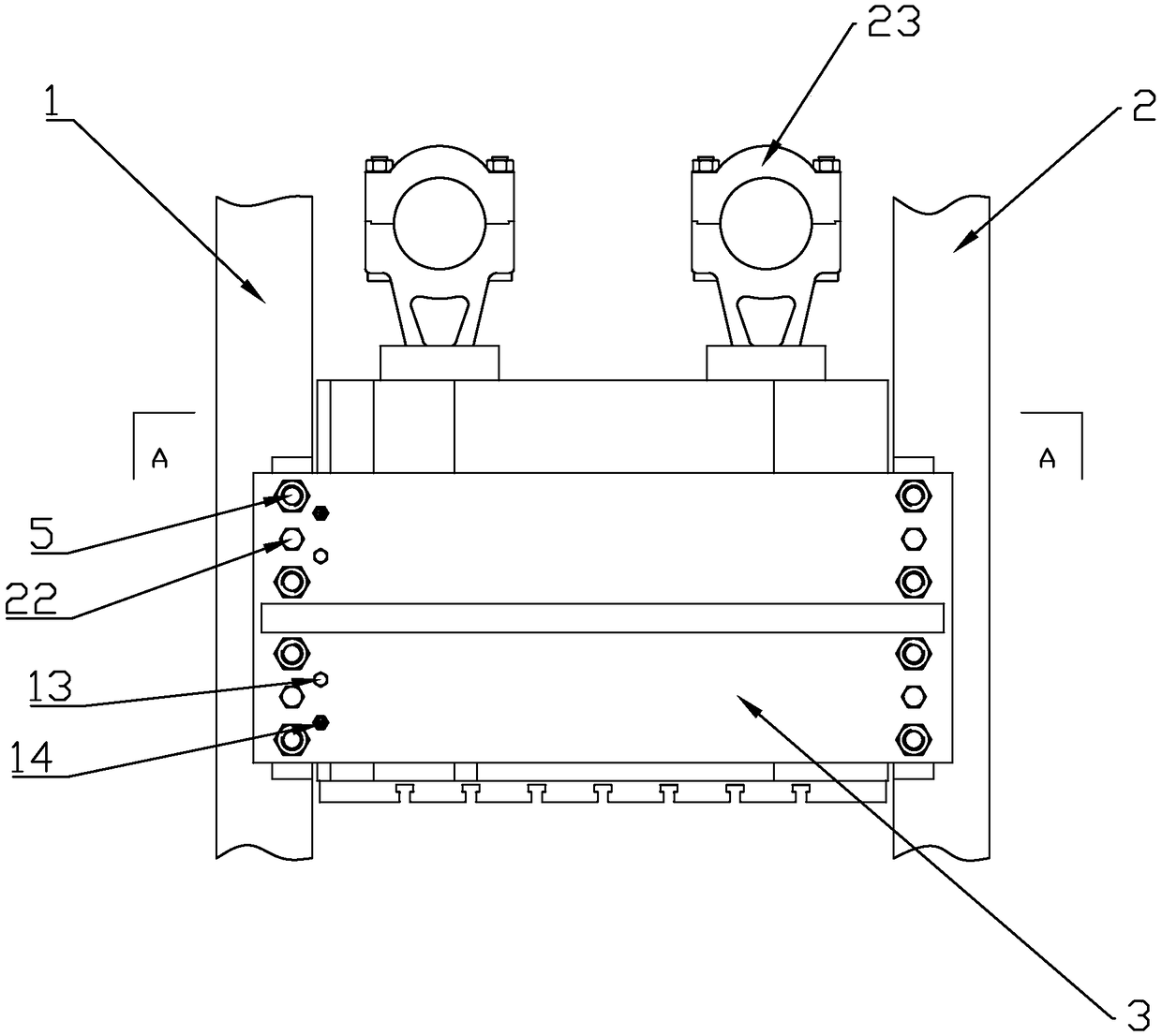

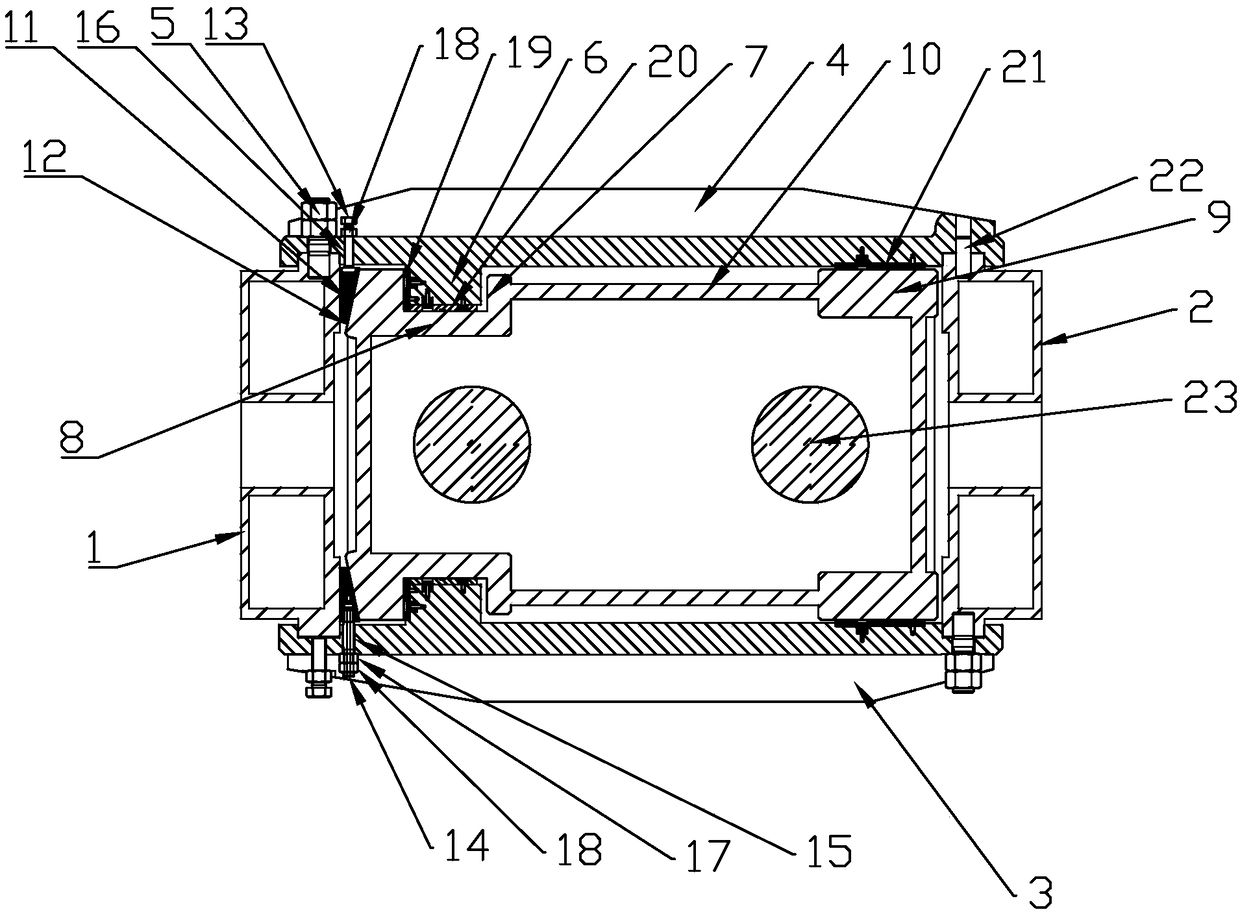

[0021] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0022] like Figure 1-2 As shown, a slider guide and precision adjustment structure suitable for hot stamping presses, including a left column 1 and a right column 2 located at the left and right ends of the slider, and a front guide plate 3 respectively located at the front and rear sides of the slider and the rear guide plate 4, the front guide plate 3 and the rear guide plate 4 are respectively connected with the left column 1 and the right column 2 through the guide plate adjustment bolts 5, and the left ends of the inner side walls of the front guide plate 3 and the rear guide plate 4 are symmetrical Two bumps 6 are vertically provided, and the slider is provided with a groove 7 corresponding to the bump 6, between the slider and the left column 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com