Grabbing and placing device for deburring

A technology of brushing burrs and driving devices, which is applied in the direction of grinding machine tool parts, grinding feed movement, metal processing equipment, etc., which can solve the problem of difficult to ensure position and attitude accuracy, narrow the working space range of the mechanism, and affect the normal operation of the system, etc. problem, to achieve the effect of clear motion trajectory and position accuracy, simple and light construction and installation process, and simplified end effector device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

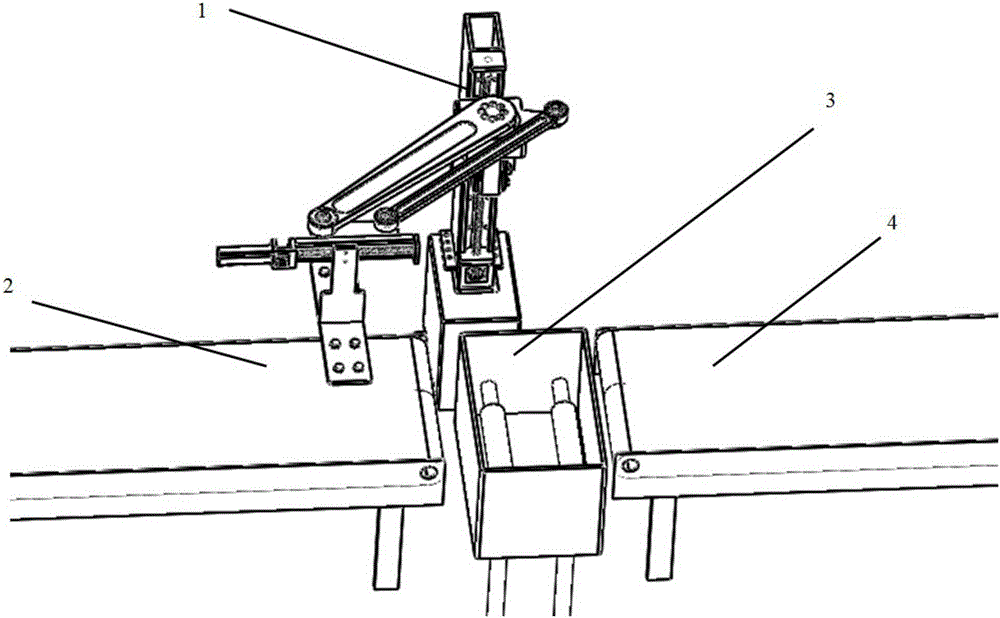

[0030] Such as figure 1 As shown, a kind of grabbing and placing device for brush burrs provided by the present invention includes a moving bracket three-degree-of-freedom handling robot 1, an input conveyor belt 2, a brush machine 3, and an output conveyor belt 4; the input conveyor belt is placed horizontally, and the brush machine It is located directly below the suction cup mounting plate when the active arm of the three-degree-of-freedom transporting robot arm conveying device on the movable support is in the middle position, and the output conveyor belt and input conveyor belt are symmetrically arranged relative to the brush machine.

[0031] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, a grabbing and placing device for brush burrs consists of a rectangular hollow column 5, a first linear module 6, a moving bracket 7, a base 8, an active arm 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com