Preparation method and application of fluorine removal material

A fluorine material and acid hydrolysis technology are applied in the field of preparation of fluorine removal materials, which can solve the problems of limited fluoride removal effect and difficulty in obtaining the roots of reeds, etc., so as to improve the fluoride removal effect, reduce the preparation cost, and increase the fluorine adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of a fluorine removal material of the present invention is described in detail through Examples 1 to 10 and Comparative Example 1.

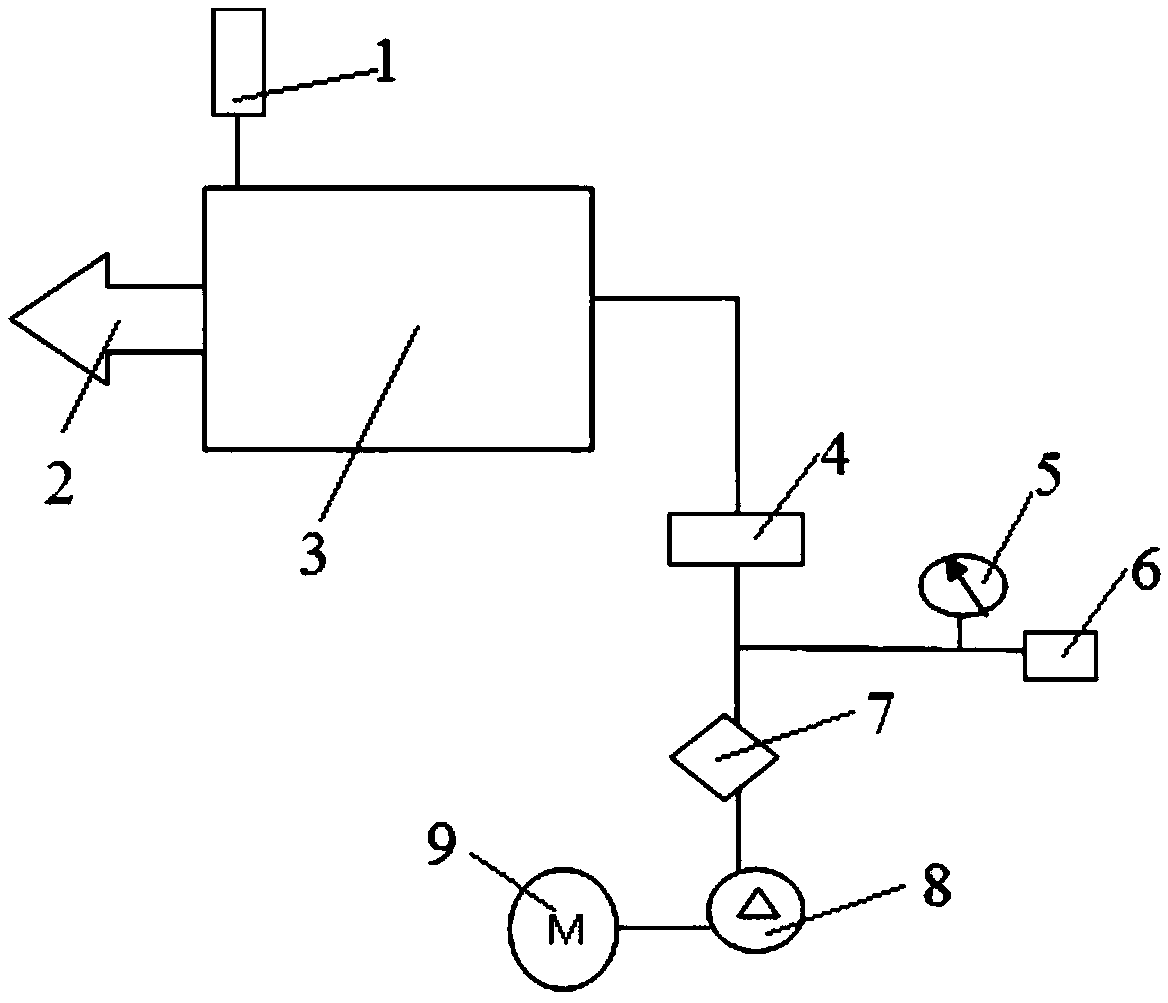

[0036] Such as figure 1As shown, the pneumatic puffing device in Embodiment 1 to Embodiment 10 of the present invention includes a material chamber 3, a reversing valve 4, an air filter 7 and an air pump 8. One end of the material chamber 3 is provided with a material port 2, and the material chamber 3 is installed above the quick discharge valve 1, the material chamber 3 is sequentially connected with the reversing valve 4, the air filter 7 and the air pump 8, and a pneumatic overflow valve is set between the reversing valve 4 and the air filter 7 6. An air pressure gauge 5 is installed on the pneumatic overflow valve 6, and the air pump 8 is connected with a motor 9.

Embodiment 1

[0038] The preparation method of the defluorination material of the present embodiment comprises the following steps:

[0039] Step 1, cleaning and air-drying the stems of reeds after removing the soil, then crushing and passing through a 40-mesh sieve;

[0040] Step 2: Add 160 mL of acid solution to 20 g of reed stems that have passed through a 40-mesh sieve in step 1 and stir evenly to form a mixed system, then heat the mixed system to 75°C and keep it warm and reflux for 2 hours to carry out acidolysis to desugar the reed stems ; The concentration of hydrochloric acid in the acid solution is 2mol / L, and the concentration of sulfuric acid is 1mol / L;

[0041] Step 3. Separating the mixed system after acidolysis in step 2 from solid to liquid. The obtained solids are acidolysis residues, and then rinse the acidolysis residues with deionized water until neutral, and then under the condition of 80°C to dry;

[0042] Step 4. Place the dried acidolysis residue in step 3 in the m...

Embodiment 2

[0054] The preparation method of the defluorination material of the present embodiment comprises the following steps:

[0055] Step 1, cleaning and air-drying the stems of reeds after removing the soil, then crushing and passing through a 40-mesh sieve;

[0056] Step 2: Add 160 mL of acid solution to 20 g of reed stems that have passed through a 40-mesh sieve in step 1 and stir evenly to form a mixed system, then heat the mixed system to 75°C and keep it warm and reflux for 3 hours to carry out acidolysis to desugar the reed stems , to obtain acidolysis solution; the concentration of hydrochloric acid in the acid solution is 2mol / L, and the concentration of sulfuric acid is 2.5mol / L;

[0057] Step 3. Separating the mixed system after acidolysis in step 2 from solid to liquid. The obtained solids are acidolysis residues, and then rinse the acidolysis residues with deionized water until neutral, and then under the condition of 80°C to dry;

[0058] Step 4. Place the dried acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com