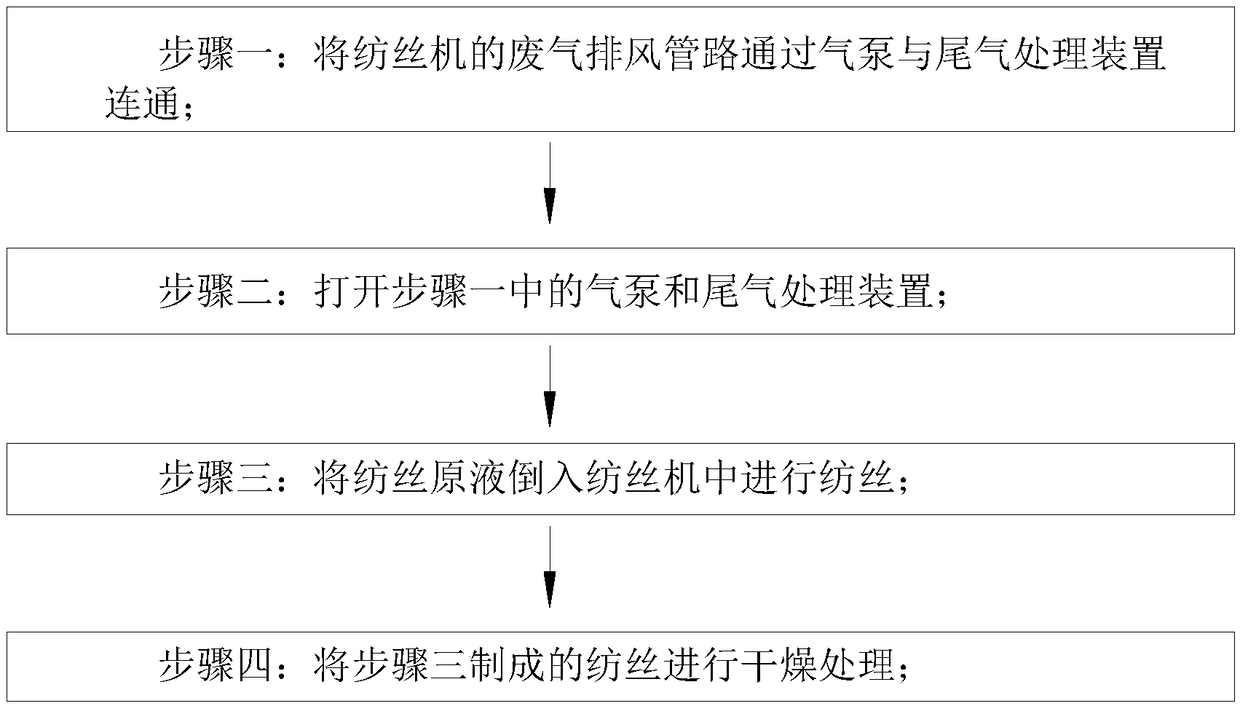

Polyurethane spinning method

A polyurethane and spinning technology, which is applied in the field of gas treatment equipment, can solve the problems of impurity filtration, restriction, and inability to use tail gas power, etc., and achieves the effect of improving purification efficiency and purification capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

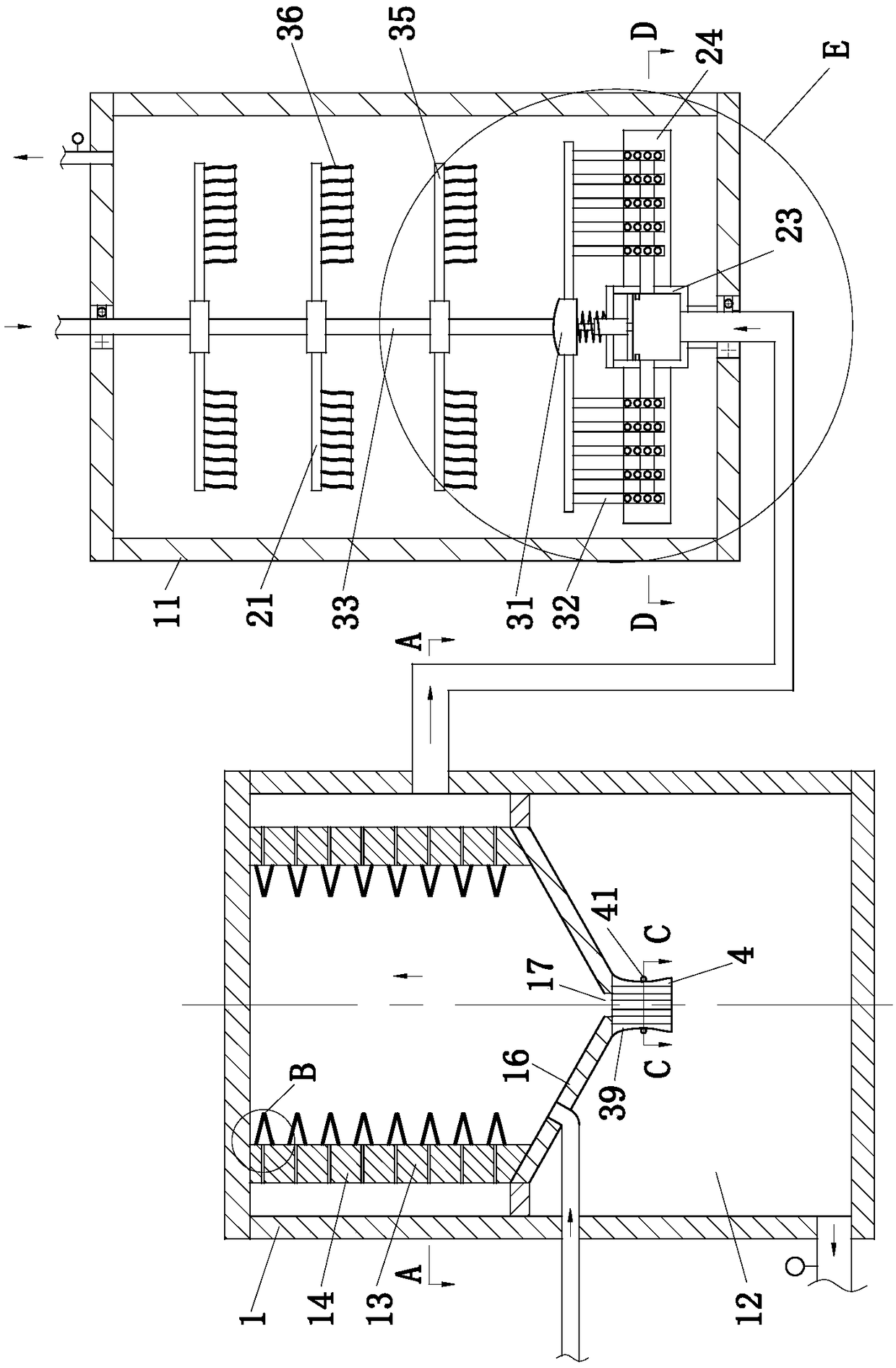

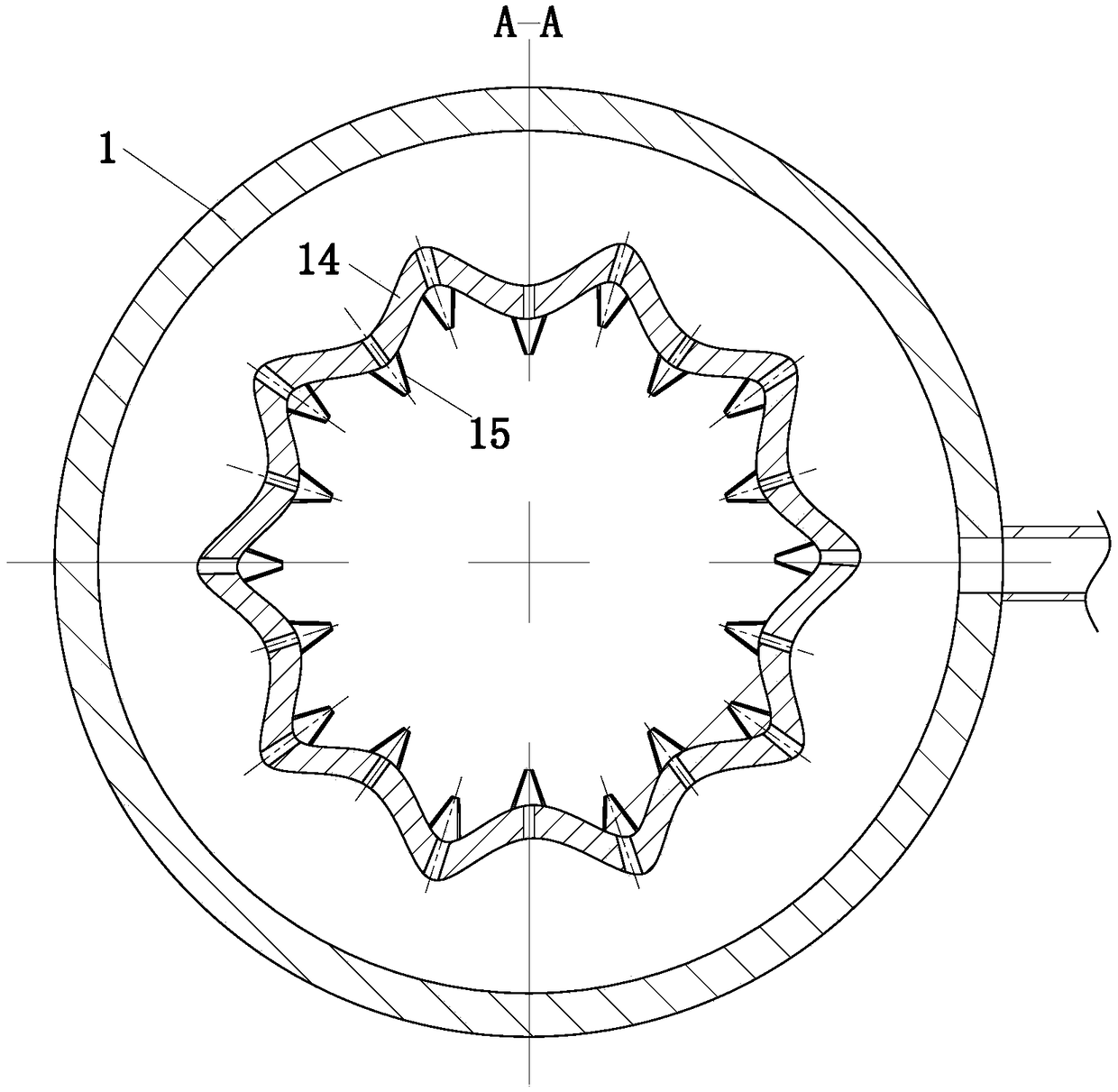

[0045] As an embodiment of the present invention, the air flotation module 2 includes a hollow shaft 22, an air storage tank 23, a rotating plate 24 and a shielding unit 25; the hollow shaft 22 is rotatably connected to the conduit through a bearing; the upper end of the hollow shaft 22 It is fixedly connected with the gas storage tank 23, and the hollow shaft 22 is used to transport the tail gas in the conduit to the gas storage tank 23; the number of the rotating plates 24 is multiple, and the multiple rotating plates 24 are evenly installed in a circular arrangement. The side wall outer surface of the gas tank 23; the side surface of the rotating plate 24 in contact with the gas tank 23, the surface is provided with a No. 1 gas storage tank 26; the top surface of the rotating plate 24 is provided with a No. 2 gas storage tank 27, The side surface of the rotating plate 24 is provided with an air injection hole 28 communicating with the No. 2 air storage tank 27; the air injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com