EPS brushless motor rotor core structure

A rotor iron core, brushless motor technology, applied in the magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problem of low moment of inertia, reduce the moment of inertia, reduce the harmonic content of back EMF, The effect of reducing the cost of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the invention is further described.

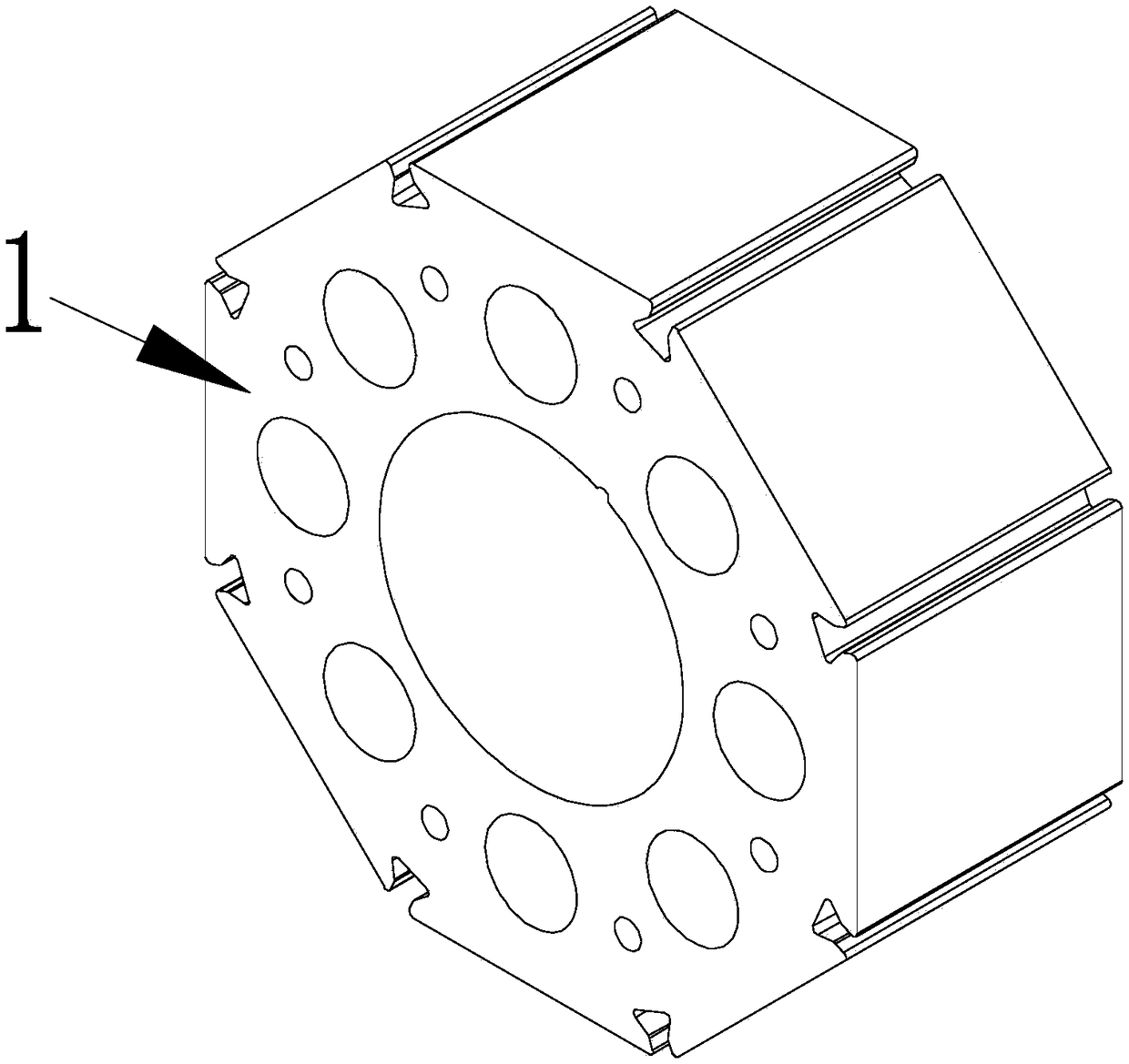

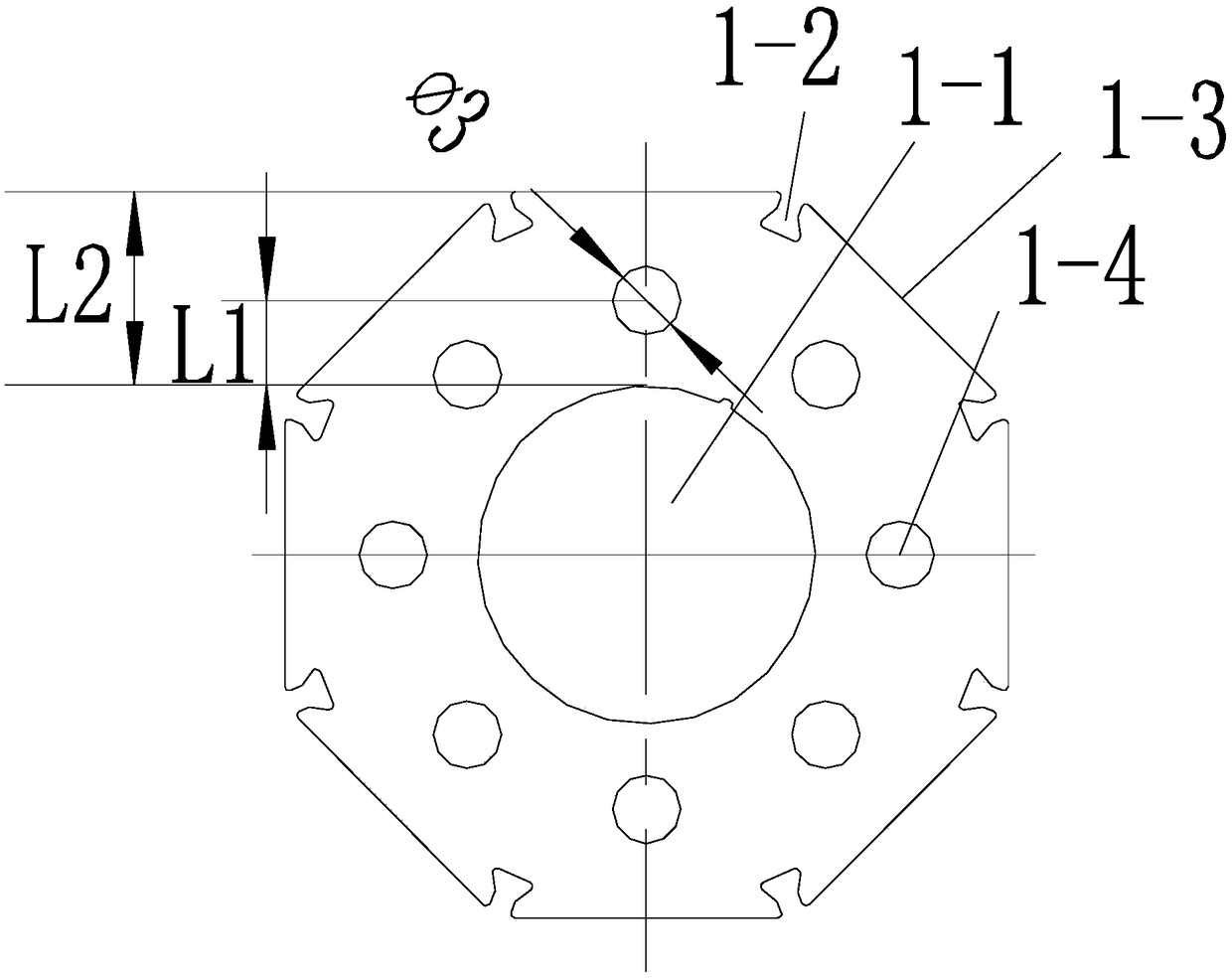

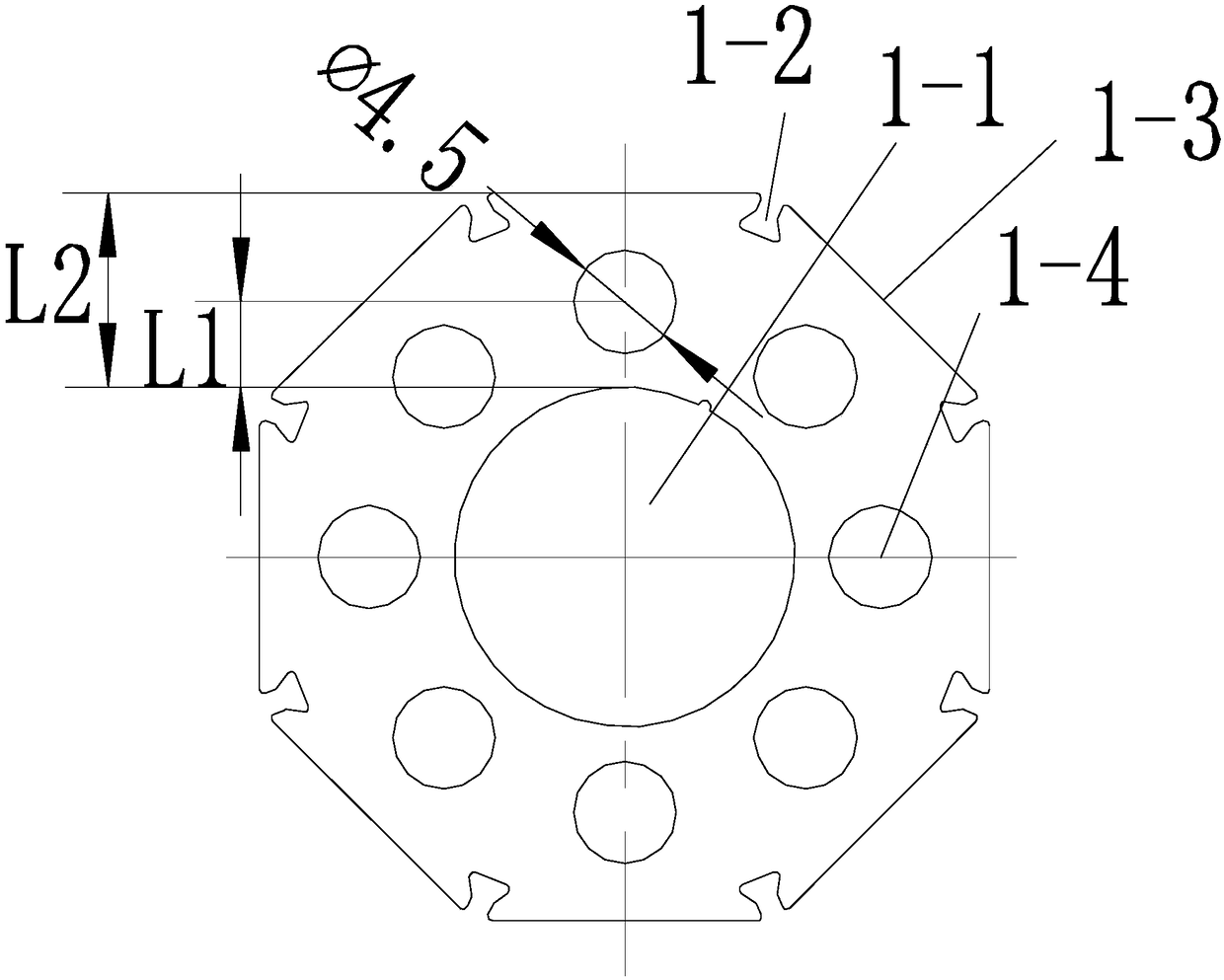

[0016] like figure 1 , 2 , 3, the EPS brushless motor rotor core structure provided by this embodiment includes a rotor punch 1, and a plurality of rotor punches 1 are laminated to form a rotor core, which is characterized in that: the geometric center of the rotor punch 1 There is a shaft hole 1-1 on the top, and several plastic sealing grooves 1-2 are provided on the edge of the rotor punching plate 1. Between the two adjacent plastic sealing grooves 1-2 is a magnetic steel mounting surface 1-3, and the magnetic steel Several additional holes 1-4 are provided between the mounting surface 1-3 and the shaft hole 1-1, the shortest distance from the geometric center of the additional holes 1-4 to the shaft hole 1-1 is L1, and the magnetic steel mounting surface 1 The shortest distance between -3 and the shaft hole 1-1 is L2, and L1 / L2 is less than or equal to 0.5.

[0017] The numbers of the add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com