Collector ring for high temperature and high humidity environment

A high-temperature, high-humidity, slip ring technology, applied in the field of slip rings, can solve problems affecting service life and conductive effect, and achieve the effects of convenient replacement of dry parts, improved service life, and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

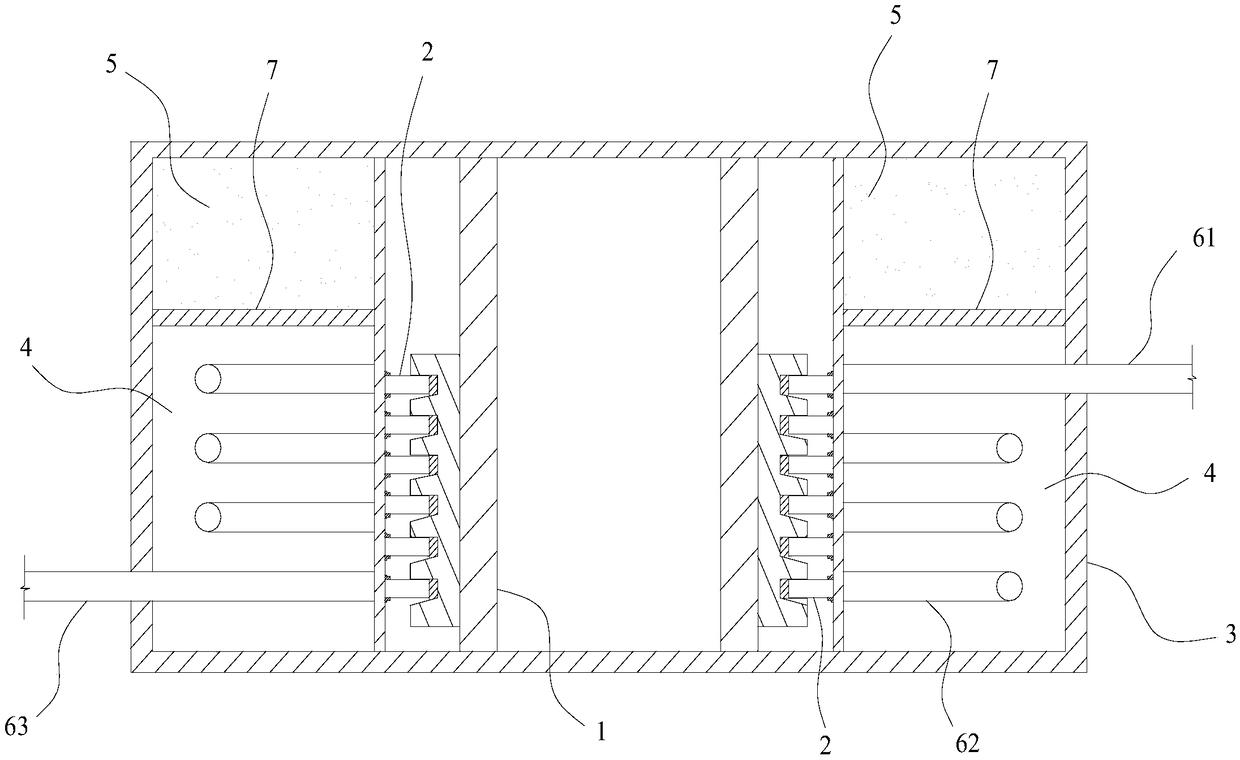

[0026] Such as figure 1 As shown, a bus ring for high temperature and high humidity environment according to the present invention includes a ring core 1, a brush 2 and a housing 3, and the outer surface of the ring core 1 is provided with multiple ring-shaped grooves at intervals, each A metal ring is correspondingly arranged in each of the ring-shaped grooves. Preferably, the bottom surface of the ring-shaped groove is a slope, which is conducive to dropping the grinding produced by wear as soon as possible, avoiding excessive accumulation, and affecting the conductive effect and heat dissipation effect. The brush 2 is connected to the inner surface of the housing 3, the end of the brush 2 is in sliding contact with the metal ring on the ring core 1, and the housing 3 is provided with a cavity 4, the cavity A partition 7 is provided in the cavity 4, and the partition 7 is provided with several through holes, and the drying part 5 is arranged in the cavity 4 above the partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com