A kind of preparation method of lithium iron phosphate/lithium metaaluminate composite cathode material

A composite positive electrode material, lithium metaaluminate technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of poor rate performance and cycle performance, poor compatibility, lithium ion conductivity There is no improvement in the efficiency and other problems, and the effect of improving the cycle performance, high consistency, and improving the ability of absorbing and retaining liquid is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

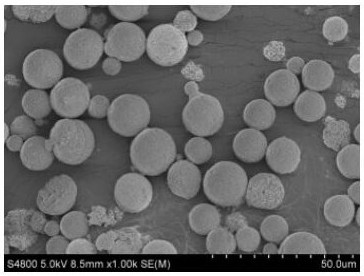

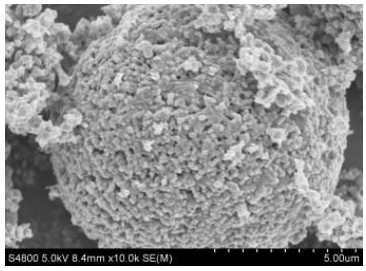

Image

Examples

Embodiment 1

[0023] A preparation method of lithium iron phosphate / lithium metaaluminate composite material, comprising the following steps:

[0024] 1) Preparation of lithium iron phosphate precursor:

[0025] Take 7.4g (0.1mol) of lithium carbonate, 29.8 (0.2mol) of ammonium phosphate, add 500ml of water to dissolve, mix well; then weigh 5.8g (0.02mol) of theophylline, add 100ml of water to dissolve, and add 3.6g of (0.2mol) ferrous nitrate, mix well; then mix the above two solutions, and adjust the pH value of the mixed solution to 7 by carbon dioxide, stir and fully react at 95°C for 12h, and obtain lithium iron phosphate precursor A after filtration ;

[0026] 2) Preparation of porous lithium metaaluminate airgel:

[0027] Preparation of porous lithium metaaluminate airgel: 10 g of sodium metaaluminate solution was adjusted to pH 8 with 0.1 mol / L hydrochloric acid to form sol aluminum hydroxide sol. The aluminum hydroxide sol was put into an oven and dried at a temperature of 50° C...

Embodiment 2

[0031] 1) Preparation of lithium iron phosphate precursor:

[0032] Weigh 6.66g (0.09mol) lithium carbonate, 2.07g (0.018mol) ammonium dihydrogen phosphate, add 500ml water to dissolve, mix well; then weigh 4.83g (0.015mol) cyanidin, add 100ml water to dissolve, and Add 2.286g (0.018mol) ferrous chloride to the solution, mix well; then mix the above solution, adjust the pH value of the mixed solution to 6.5, stir and fully react at 90°C for 6h, and obtain lithium iron phosphate after filtration Precursor A;

[0033] 2) Preparation of porous lithium metaaluminate airgel:

[0034] Preparation of porous lithium metaaluminate airgel: 10 g of sodium metaaluminate solution was adjusted to pH 8 with 0.1 mol / L hydrochloric acid to form sol aluminum hydroxide sol. The aluminum hydroxide sol was dried in an oven at 50°C for 3 h to form an aluminum hydroxide gel. Then place it in 100ml, 0.1mol / l lithium carbonate solution to form a lithium metaaluminate gel, then put the gel into a hi...

Embodiment 3

[0038] 1) Preparation of lithium iron phosphate precursor:

[0039] Weigh 8.14g (0.11mol) of lithium carbonate, 2.90g (0.022mol) of diammonium hydrogen phosphate, add 500ml of water to dissolve, mix well; then weigh 12.2g (0.02mol) of rutin, add 100ml of water to dissolve, and add to the solution Add 1.58g (0.022mol) of ferrous oxide into the solution, mix well; then mix the above solutions, adjust the pH value of the mixed solution to 7.5, stir and fully react at 100°C for 6h, and obtain lithium iron phosphate precursor A after filtration ;

[0040] 2) Preparation of porous lithium metaaluminate airgel:

[0041] Preparation of porous lithium metaaluminate airgel: 10 g of sodium metaaluminate solution was adjusted to pH 8 with 0.1 mol / L hydrochloric acid to form sol aluminum hydroxide sol. The aluminum hydroxide sol was dried in an oven at 50°C for 3 hours to form an aluminum hydroxide gel. Then place it in 100ml, 1.0mol / l lithium carbonate solution to form a lithium metaal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com