Diamond color grading automatic measuring device

A technology of color grading and automatic measurement, applied in the direction of color/spectral characteristic measurement, jewelry testing, etc., to achieve the effect of ensuring consistency, ensuring analysis results, and reducing system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

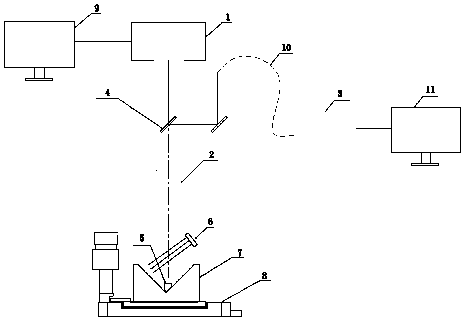

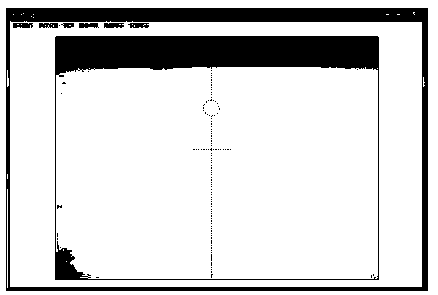

[0033] Embodiment 1, this embodiment provides the concrete structure of device, as figure 1 As shown, it mainly includes two parts: the microscopic area positioning system and the automatic spectrum acquisition and calculation system. Microscope positioning system includes a V-shaped sample slot 7 and a whiteboard, the V-shaped sample slot 7 is fixed on an adjustable two-dimensional platform 8, a light source 6 is arranged on one side of the sample 5, and a zoom lens 2 is arranged directly above the sample. Just above and one side of the variable-magnification focusing lens 2 are respectively provided with a semi-transparent half-mirror 4, these two half-transparent mirrors are arranged in parallel, and form an angle of 45 ° with the horizontal plane, the variable-magnification focusing lens 2 top A CCD detector 1 is arranged above the half mirror. CCD detector 1, variable magnification focusing lens 2, and half mirror 4 are fixed by an integral frame, and then the integral f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com