Structure test system with tension-compression bending shear force applying function

A structural test and application device technology, applied in the direction of using a stable bending force to test the material strength, using a stable shear force to test the material strength, using a stable tension/pressure test to test the material strength, etc. Test the problems of the combined effect of the three forces to achieve the effects of quick assembly and disassembly, good adjustability and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

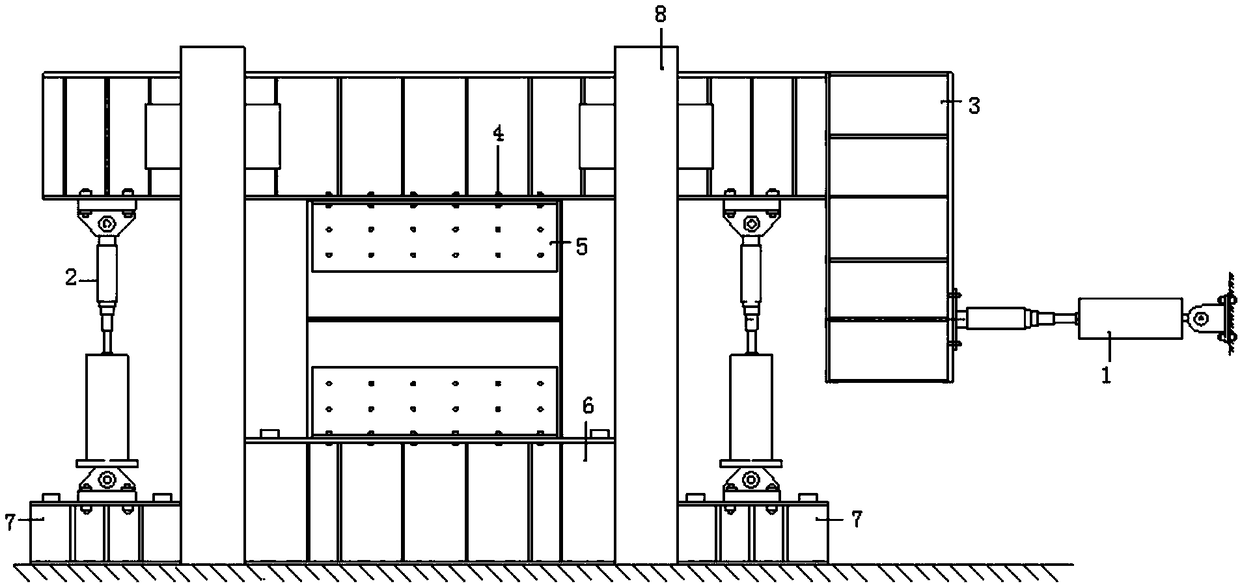

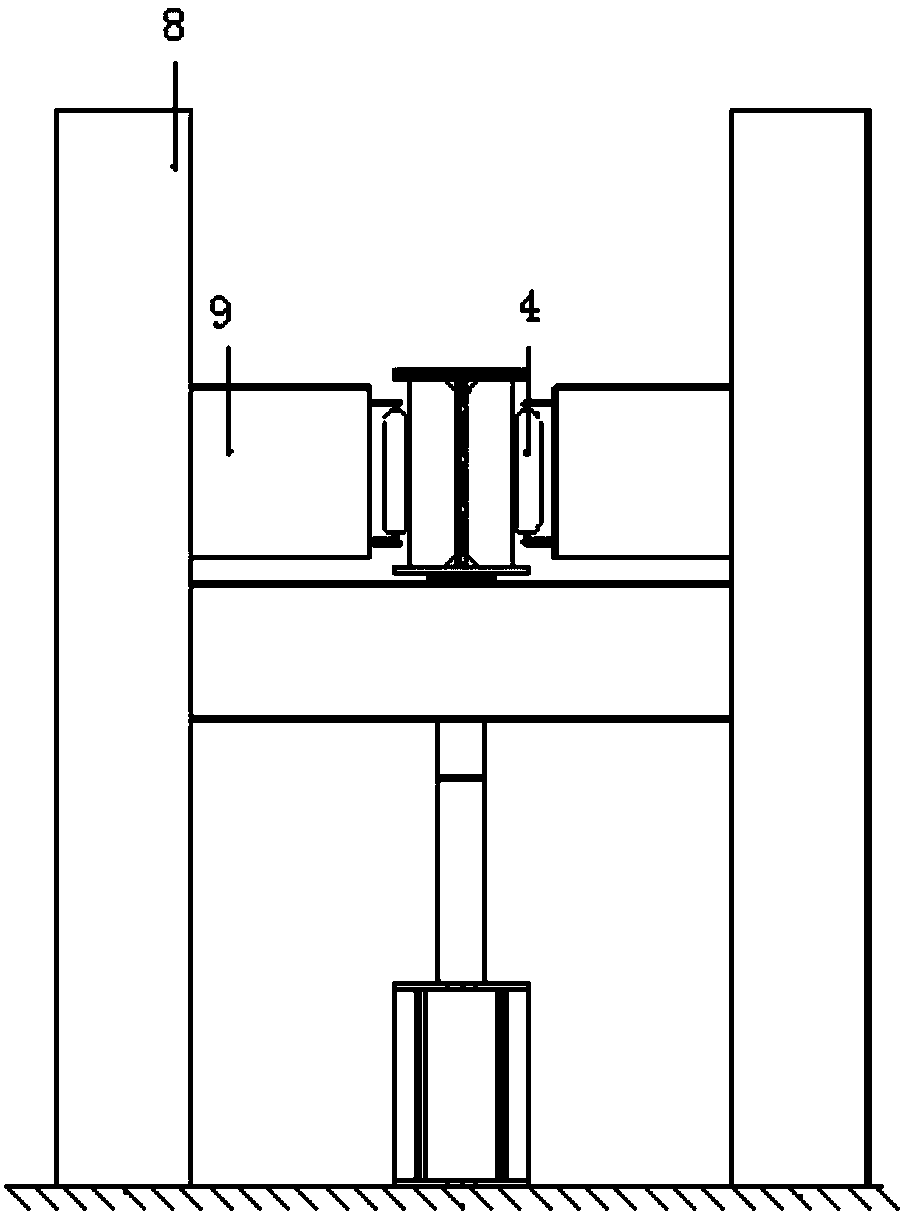

[0036] Such as figure 1 , 2 As shown, the structural test system that can apply tension, compression, bending and shear forces includes:

[0037] The L-shaped beam 3 includes a horizontal part and a vertical part integrally connected, and the bottom surface of the middle section of the horizontal part is rigidly connected with the upper part of the test piece;

[0038] Horizontal force applying device 1, one end is connected to the reaction force frame or the reaction force wall, and the other end is connected to the vertical part of the L-shaped beam 3;

[0039] Vertical force applying device 2, the upper end is hinged with the bottom surface of the horizontal part of the L-shaped beam 3, the lower end is hinged with the support 7, and the support 7 is connected with the ground foundation or the trough. There are two vertical force applying devices 2, one One end of the horizontal part of the L-shaped beam 3 away from the vertical part is arranged, and the other is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com