Prestressed actively-coolable artillery pipe made from composite material

A composite material, artillery barrel technology, applied in cooling or heating systems, weapon accessories, offensive equipment, etc., can solve the problem of not considering active cooling, difficult to large-scale promotion, artillery manufacturing technical requirements and high costs, to reduce the temperature. , the effect of increasing the shooting power and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

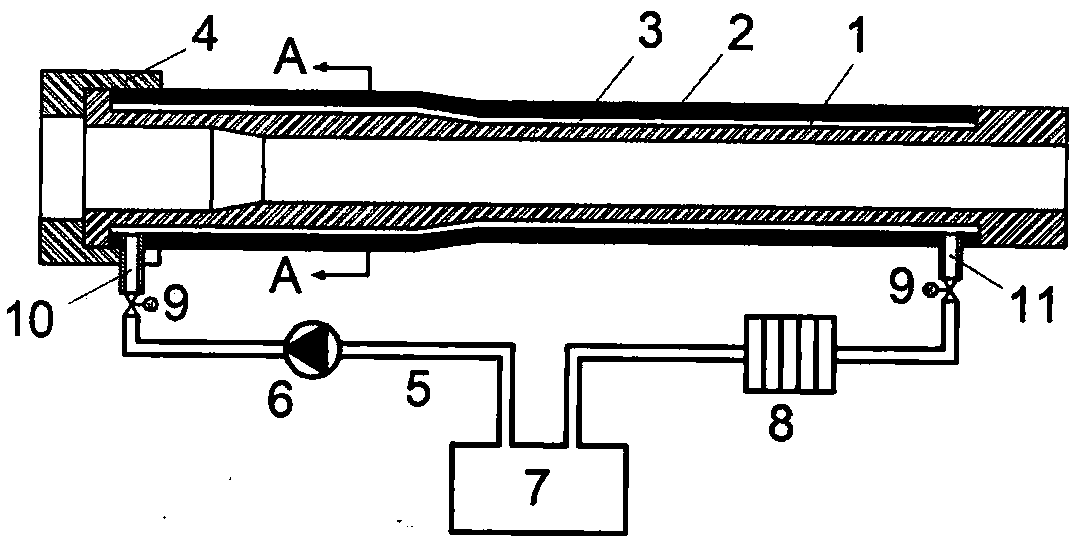

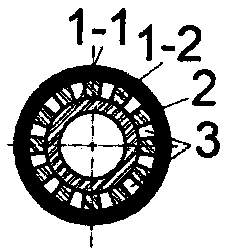

[0016] A prestressed cannon active cooling composite artillery barrel, comprising an artillery barrel 1 and a gun breech 4, and a carbon fiber composite reinforcement layer 2 is arranged outside the artillery barrel; the artillery barrel includes a steel inner liner 1-1, Steel interlayer pressure-bearing spacers 1-2 are arranged outside the steel liner pipe, and the gap between the liner pipe and the carbon fiber composite material reinforcement layer is a cooling channel 3, and the cooling channel is provided with a coolant inlet 10 and an outlet 11 , the inlet is connected to the coolant storage tank 7 through a pipeline 5 provided with a pump 6, and the outlet is connected to the coolant storage tank through a pipeline provided with a radiator 8; the carbon fiber composite reinforcement layer is wound on a steel interlayer bearing Pressure spacer appearance. There is also a valve 9 in the figure.

[0017] The coolant inlet is located at the rear end of the cooling channel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com