Method for preparing water-soluble lignin

A technology of water-soluble lignin and lignocellulose, applied in the field of renewable resources, can solve the problems of limited application, poor solubility, low economic benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

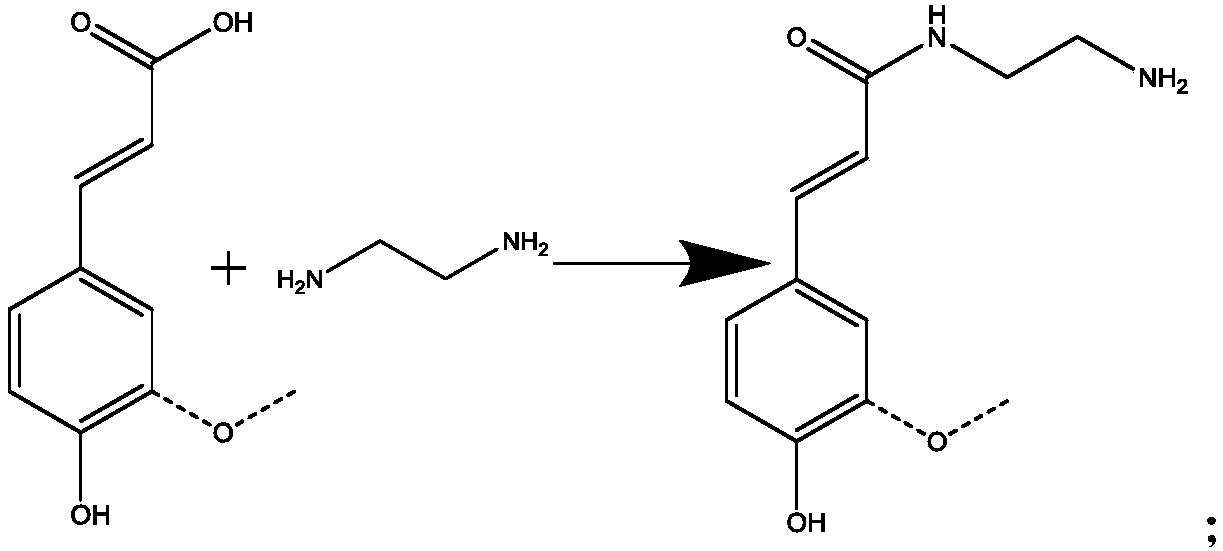

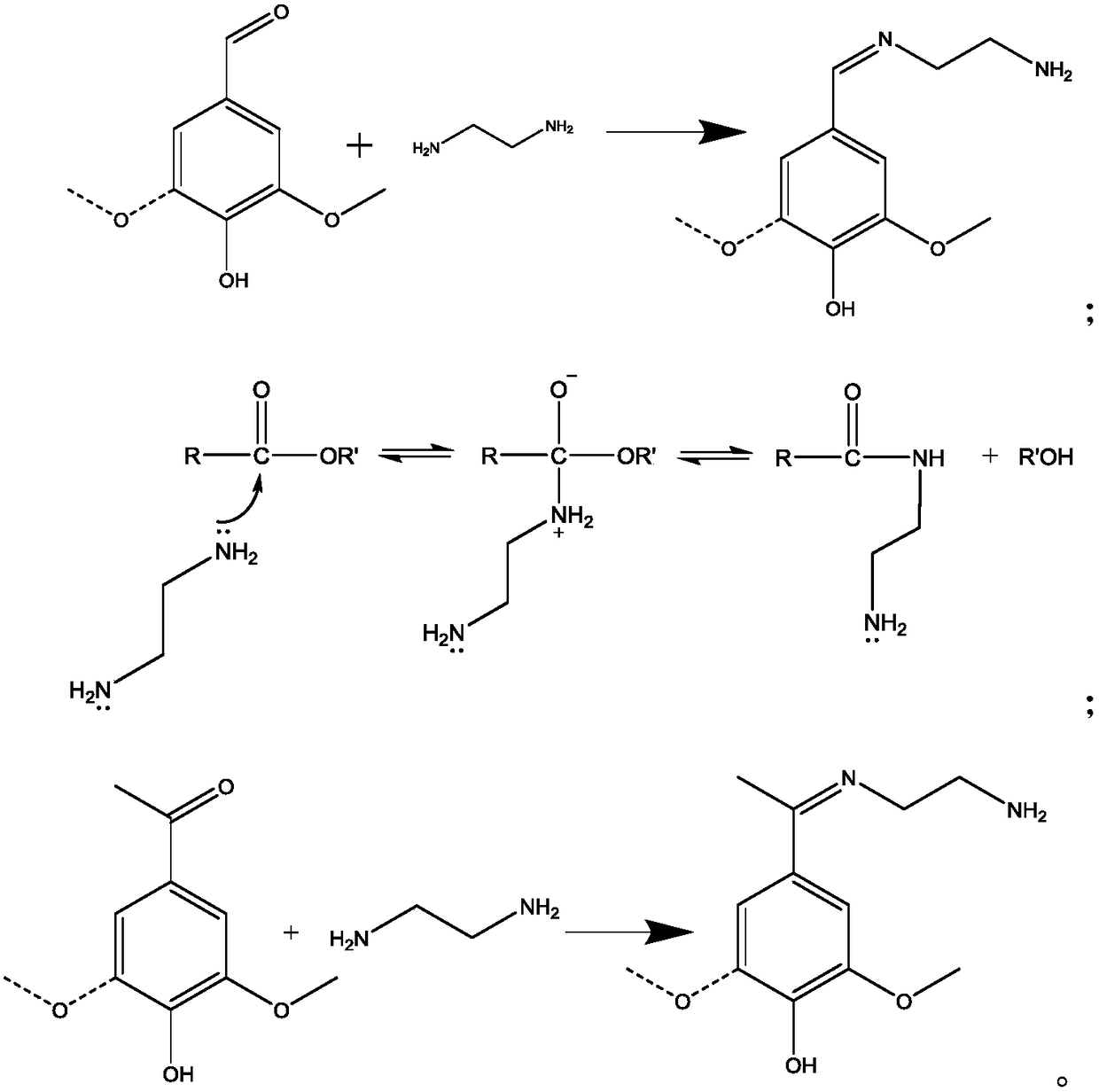

[0018] In view of the extensiveness of lignocellulose resources and the current situation that the water solubility of lignin limits its application, the application provides a method for preparing water-soluble lignin, including:

[0019] React lignocellulose powder with ethylenediamine in a closed container, dry and then wash and extract with water to obtain water-soluble lignin;

[0020] The ratio of the lignocellulose powder to the ethylenediamine is 1g:(0.4-1)ml; the reaction temperature is 50-180°C, and the reaction time is 0.5-4h.

[0021] This application uses ethylenediamine to treat lignin in lignocellulose, the connection between the treated lignin and hemicellulose is broken, and a certain amount of amino groups are introduced at the same time, so the treated lignin is acid-soluble and water-soluble Sexual enhancement.

[0022] Specifically, the lignocellulose is not particularly limited in this application, and may be lignocellulose well known to those skilled in...

Embodiment 1

[0032] Take 1.0g of straw powder, add 0.6ml of ethylenediamine, react at 120°C for 1h, dry at 60°C, wash once with 50ml of water and then dry. Measure the volume of washing liquid and the concentration of soluble lignin as shown in Table 1.

[0033] The concentration data table of the water-soluble lignin prepared in the present embodiment of table 1

[0034] frequency

[0035] The present invention detects that the soluble lignin content in the washing liquid is 0.126g, and the final lignin conversion rate is 62.9%.

Embodiment 2

[0037] Take 1.0g of straw powder, add 1.0ml of ethylenediamine, react at 100°C for 0.5h, dry at 105°C, wash with 15ml of water three times and then dry, measure the volume of washing liquid and the concentration of water-soluble lignin as shown in Table 2 Show,

[0038] The concentration data sheet of the water-soluble lignin prepared in the present embodiment of table 2

[0039] frequency

[0040] The present invention detects that the soluble lignin content in the washing liquid is 0.106g, and the final lignin conversion rate is 53.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com