Ecological rock and method for preparing same

An ecological stone and fabric technology, applied in clay products, other household appliances, household appliances, etc., can solve the problems of lack of stone resources, ecological environment damage, high grinding consumption, etc. The effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing an ecological stone, characterized in that it comprises:

[0036] Batching steps: Weigh the raw materials of the fabric and base material according to the formula ratio; batching is carried out through sophisticated batching and measuring equipment to ensure the accuracy of the product formula, ensure the product quality is good, the color number is small, and the product color is stable, which meets the requirements of the project. Large area paving needs.

[0037] Ball milling and stale steps: add the fabric raw materials of the formula amount into the ball mill for sufficient ball milling, then use the slurry storage equipment to stale the slurry, and after mixing evenly, obtain the fabric slurry; add the bottom material raw materials of the formula amount into the ball mill for fully The ball mill, and then use the slurry storage equipment to stale the slurry, after mixing evenly, get the bottom material slurry

[0038] Spray drying step: dry...

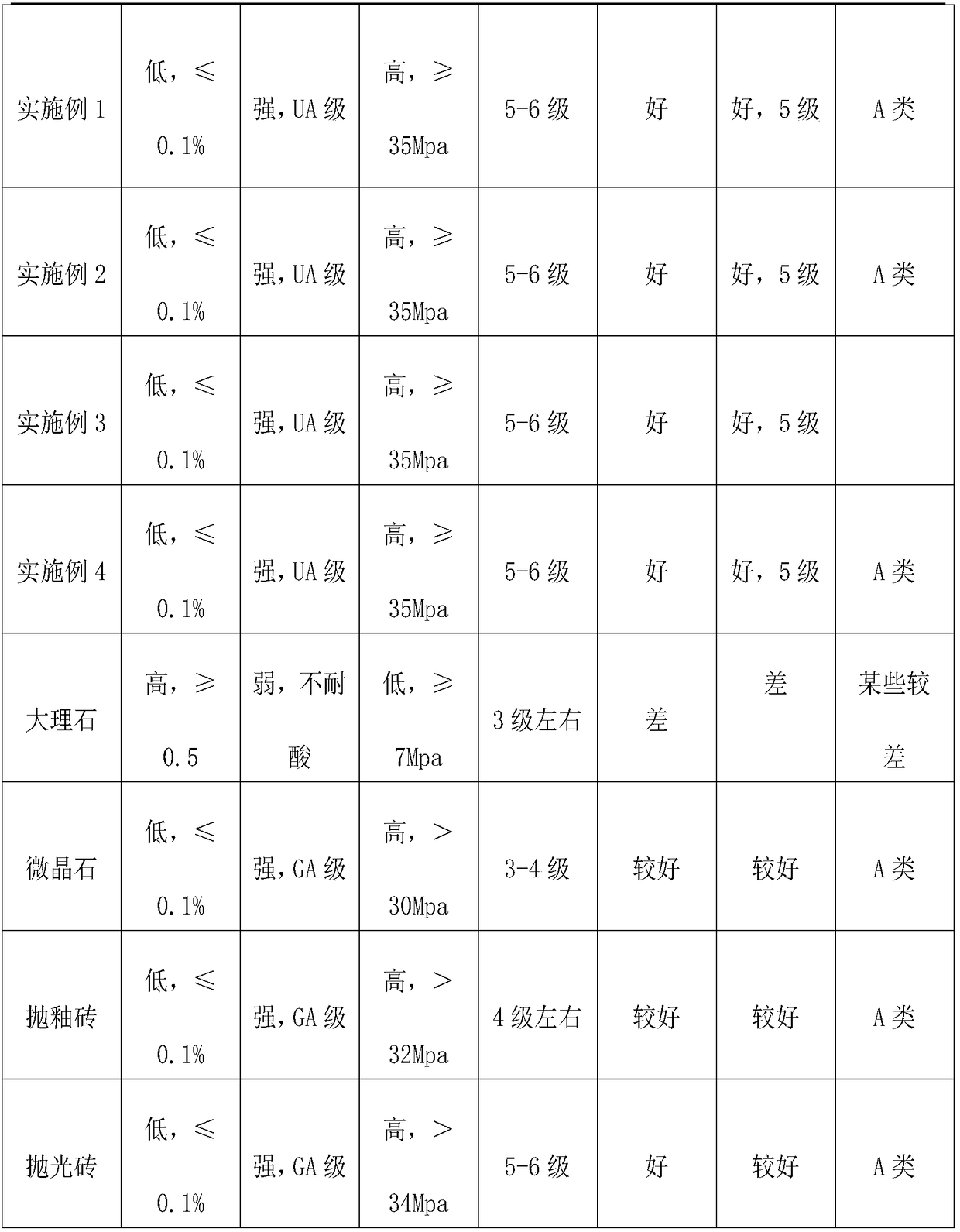

Embodiment 1

[0047] A method for preparing an ecological stone, comprising:

[0048] Ingredients step: Weigh the fabric raw materials and bottom material raw materials respectively according to the formula ratio; wherein, the fabric is prepared from the following raw materials in terms of weight percentage: ball clay 9%, super white ball clay 9%, transparent powder 28% %, mixed sand 52%, bentonite 2%. The primer is a known ceramic tile primer in the prior art.

[0049] Ball milling and stale steps: add the fabric raw materials of the formula amount into the ball mill for sufficient ball milling, then use the slurry storage equipment to stale the slurry, and after mixing evenly, obtain the fabric slurry; add the bottom material raw materials of the formula amount into the ball mill for fully The ball mill, and then use the slurry storage equipment to stale the slurry, and after mixing evenly, obtain the bottom material slurry; in the steps of ball milling and aging, a coloring agent is als...

Embodiment 2

[0056] A method for preparing an ecological stone, comprising:

[0057] Ingredients step: Weigh the fabric raw materials and bottom material raw materials respectively according to the formula ratio; wherein, the fabric is prepared from the following raw materials in terms of weight percentage: ball clay 8%, super white ball clay 8%, transparent powder 25% %, mixed sand 58%, bentonite 1%. The primer is a known ceramic tile primer in the prior art.

[0058] Ball milling and stale steps: add the fabric raw materials of the formula amount into the ball mill for sufficient ball milling, then use the slurry storage equipment to stale the slurry, and after mixing evenly, obtain the fabric slurry; add the bottom material raw materials of the formula amount into the ball mill for fully The ball mill, and then use the slurry storage equipment to stale the slurry, and after mixing evenly, obtain the bottom material slurry; in the steps of ball milling and aging, a coloring agent is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com