A bamboo cutting machine with fixed length for lantern production is disclosed

A sizing and lantern technology, which is applied in sawing equipment, mechanical equipment, sugarcane machining, etc., can solve the problems of time-consuming and laborious, too many bamboo strips, reducing production efficiency, etc., and achieve the effect of ensuring processing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

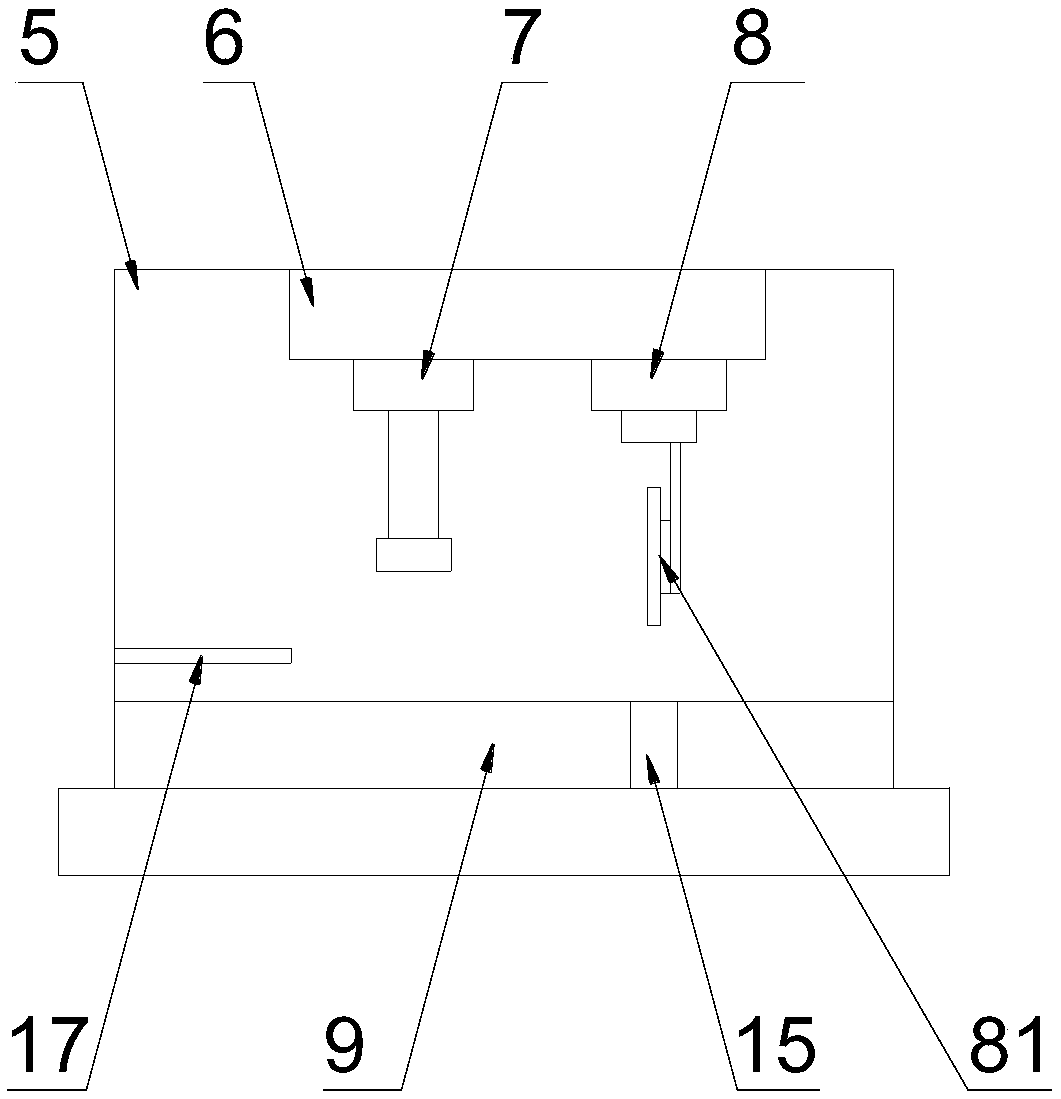

[0024] Such as Figure 1-3 as shown, figure 1 The structural representation of the bamboo cutting machine to length for lantern production proposed by the present invention; figure 2 Schematic diagram of part of the structure of the bamboo cutting machine to length for the production of lanterns proposed by the present invention; image 3 for figure 2 Side view of the midsection structure.

[0025] refer to Figure 1-3 , a kind of lantern production that the present invention proposes cuts bamboo machine with fixed length, comprises base 1, the first workbench 2, the second workbench 3, cutting device, the first fixing part 10 and the second fixing part 11; Cutting device comprises Frame 5, moving part 4, third fixed part 9, fixed frame 6, first driving mechanism 7, second driving mechanism 8, pressing part 71 and cutter assembly;

[0026] The first workbench 2 is arranged obliquely on the base, the second workbench 3 is arranged horizontally on the base 1, the first wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com