A special fixture for grinding and polishing flat soft stone

A special fixture and soft technology, which is applied to machine tools, grinding/polishing equipment, and grinding machines suitable for grinding workpiece planes. It can solve problems such as troublesome clamping and pressure control, large geometric differences, and stone damage and waste. , to achieve accurate and effective limit, prevent offset and slip, and ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

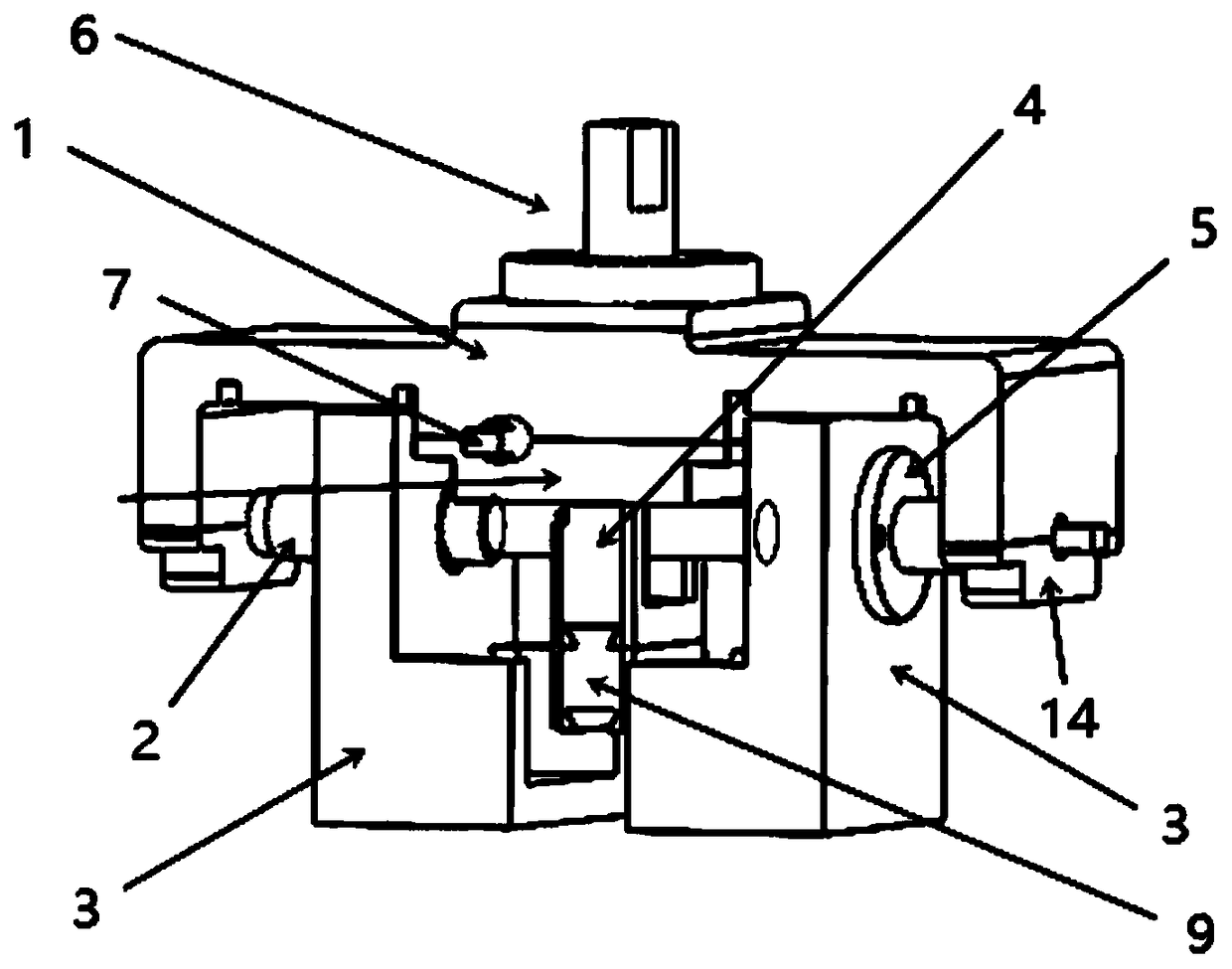

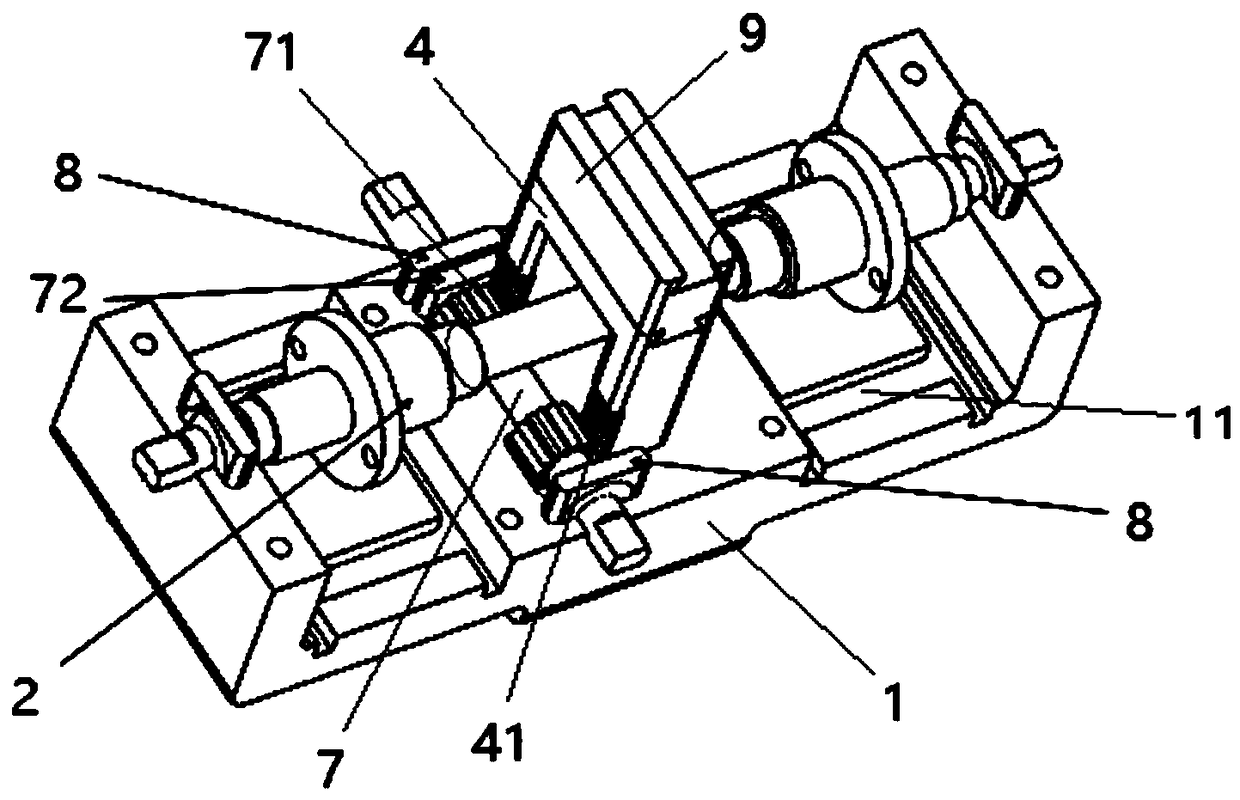

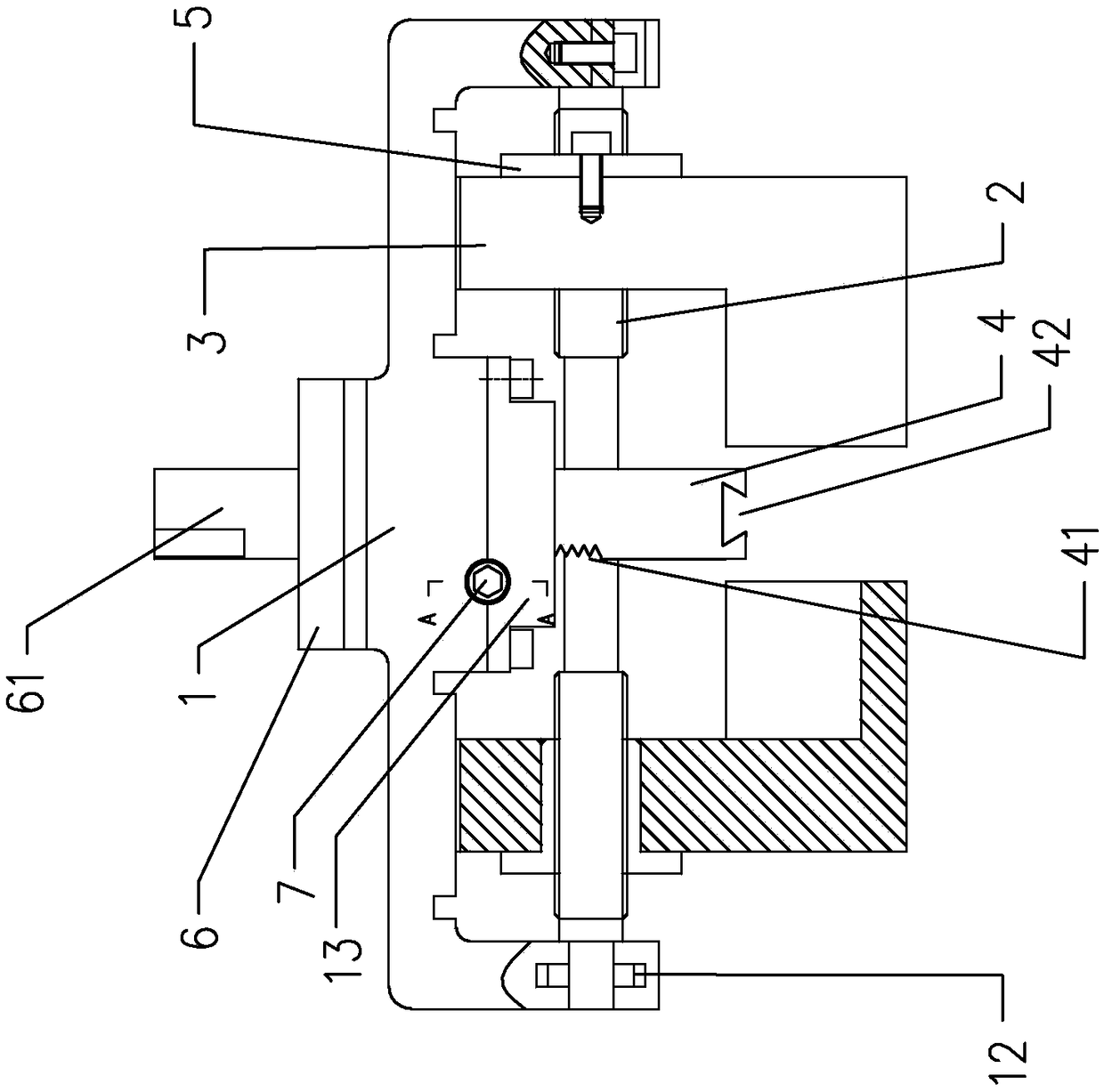

[0029] Please check Figure 1 to Figure 5 , a special fixture for grinding and polishing flat soft stone, including a base 1, a bidirectional threaded shaft 2, a clamp body 3, a limit block 4, a sleeve 5, a flange 6 and a flange 61.

[0030] The two-way threaded shaft 2 is located on the horizontal axis, and the thread directions on both sides of the two-way threaded shaft 2 are opposite. There are two clamp bodies 3, which are symmetrically arranged on both sides of the two-way threaded shaft 2, and pass through the sleeve 5 is linked with the two-way threaded shaft 2, specifically, two sleeves 5 are provided correspondingly, and the two clamping bodies 3 are respectively threaded with the two sleeves 5 through two screw holes. The direction of the thread of the sleeve 5 is opposite, and matches with the threads on both sides of the two-way threaded shaft 2. The shaft 2 cooperates with the clamp body 3 to realize the central clamping of the workpiece. .

[0031] The clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com