A saw blade deburring device

A burr removal and saw blade technology, which is applied to tool dressing of sawing machines, metal sawing equipment, grinding heads, etc., can solve the problems of uneven grinding, fast scraper wear, difficult to repair and reuse, etc., so as to improve the grinding effect and improve the use. The effect of longevity and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

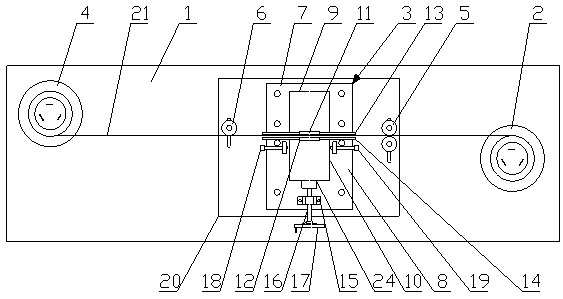

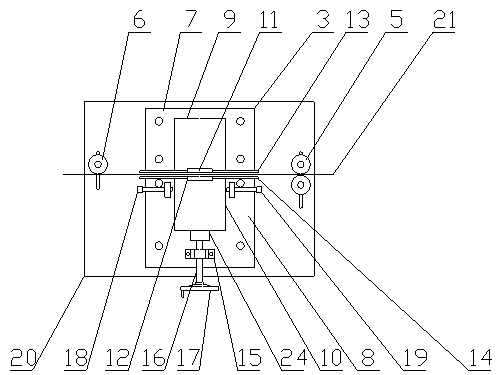

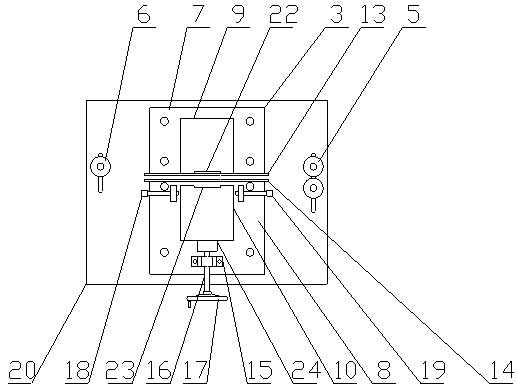

[0035] see Figure 1-7 , the embodiment of the present invention provides a device for removing burrs from a saw blade, the device includes a receiving structure 4, a grinding structure 3 and a discharging structure 2 arranged in sequence along the left and right directions, and the saw blade 21 passes through the grinding structure 3 horizontally from the discharging structure 2 (Between the fixed grinding seat 9 and the floating grinding seat 10 and the traction roller group) is wound up by the receiving structure 4, and the saw teeth of the saw blade 21 are upward.

[0036]Among them, the grinding structure 3 in this embodiment includes a base 20, traction roller sets (right traction roller set 5 and left traction roller set 6) for pulling the saw blade 21 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com