A tobacco shredding air distributor

A technology for cutting tobacco and breaking up, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problems of mixing a large number of stalks, improve combustion performance, sensory quality, and simple structure. , the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

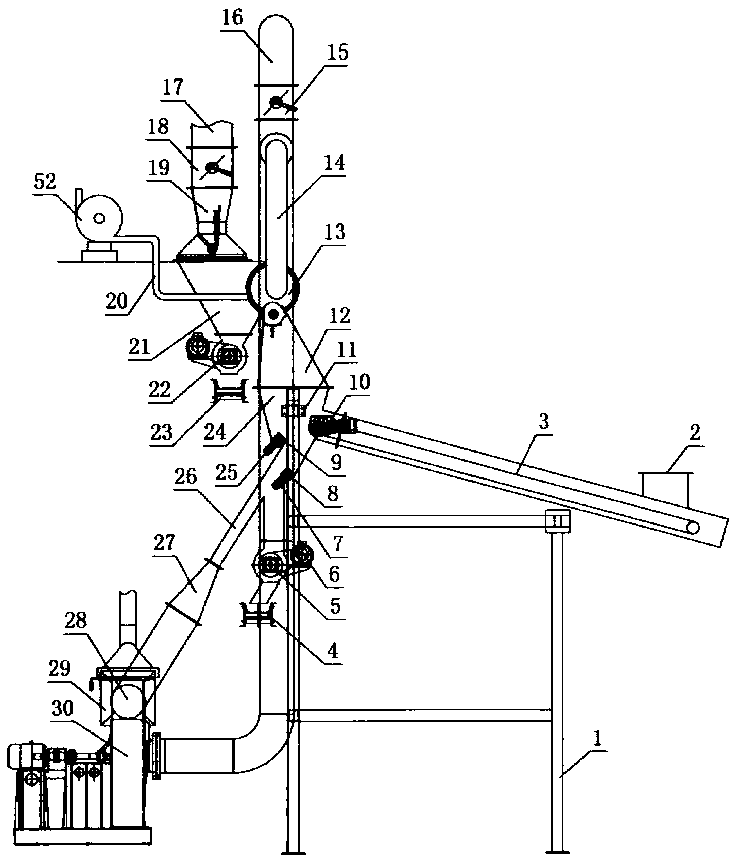

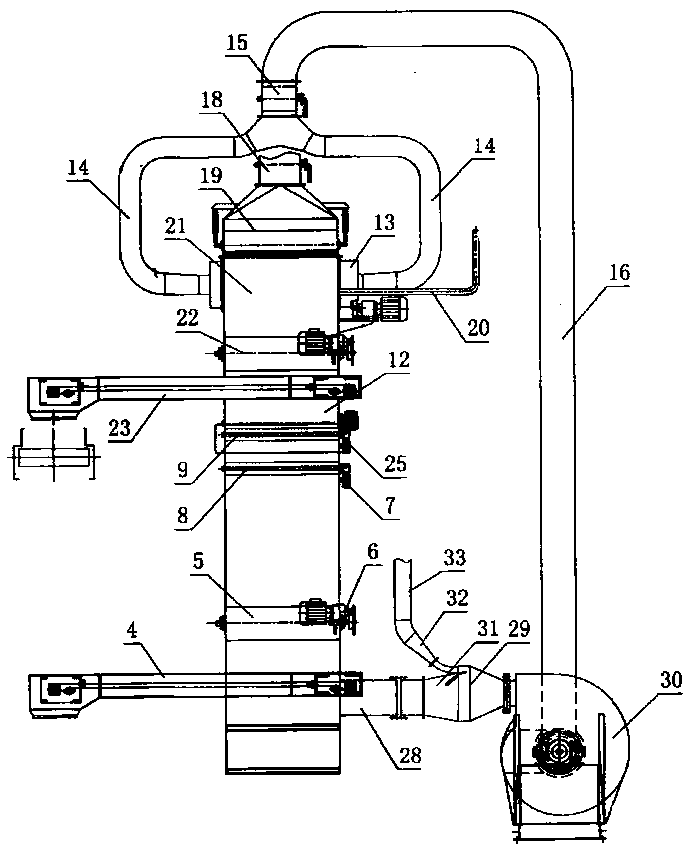

[0017] Figure 1-3 The upper left end of the frame 1 shown in is provided with shredded tobacco to separate and disperse the air sub-bin fixed connection plate 11, and the air sub-bin fixed connection plate is provided with shredded tobacco to separate and disperse the air sub-bin 12, and the shredded tobacco separates and disperses the air sub-bin by Composed of the upper wind bin and the lower wind bin, the middle part of the upper and lower wind bins is connected as a whole by a flange 24, the upper end of the shredded tobacco separation and dispersal air sub bin is provided with a suction wire transfer device 13, and the left end of the suction wire transfer device is provided with a shredded tobacco settlement Chamber 21, the lower end of the shredded tobacco settling chamber is provided with a shredded tobacco discharge valve 22, the left side of the shredded tobacco discharge valve is provided with a shredded tobacco unloading drive motor, the lower end of the shredded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com