Multifunctional tobacco shred and sliver separating device

A separation device and multi-functional technology, applied in the direction of solid separation, separation of solids from solids by air flow, tobacco, etc., can solve the problem of mixing a large number of stems, improve combustion performance and sensory quality, increase economic benefits, Optimizing the effect of process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

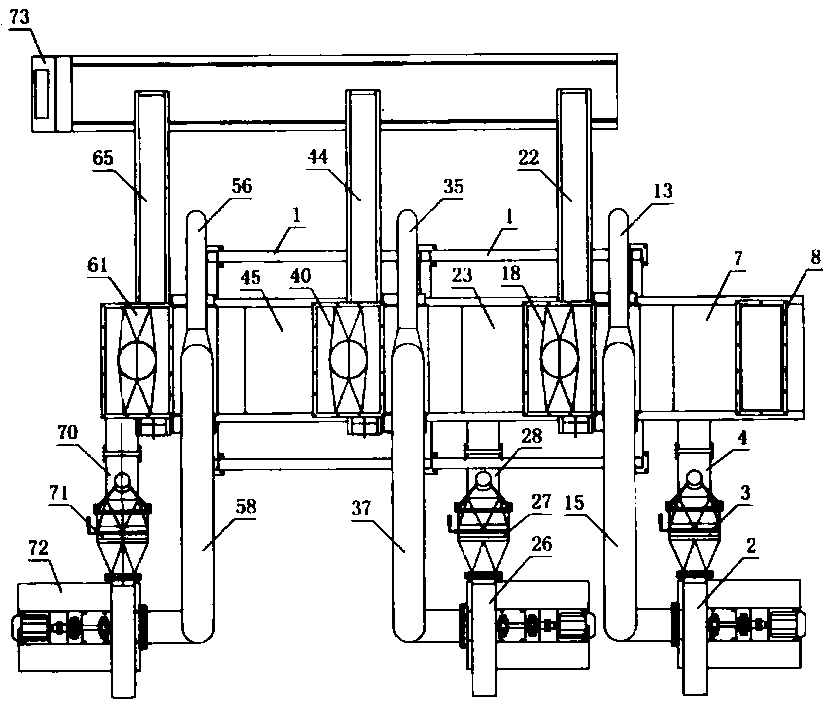

[0021] Figure 1-2 The upper right end of the frame 1 shown in the figure is provided with a first-level shredded tobacco separation air distribution bin fixed connection plate 10, and a first-level shredded tobacco separation air distribution bin 11 is housed on the first-level shredded tobacco separation air distribution bin 11 on the fixed connection plate of the first-level shredded tobacco separation air distribution bin. The upper warehouse and the lower warehouse are composed of the upper warehouse and the lower warehouse. The middle part of the upper warehouse and the lower warehouse is fixed as a whole by flange connection. The upper end of the first-level shredded tobacco separation air distribution warehouse is provided with a first-level wire suction transfer device 12, and the left end of the first-level wire suction transfer device is provided. There is a first-level shredded tobacco separation and settling chamber 20, the lower end of the first-level shredded tob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com